Glass film manufacturing method, glass roll manufacturing method, and glass film manufacturing device

A manufacturing method and technology of glass film, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., to achieve the effect of stable cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

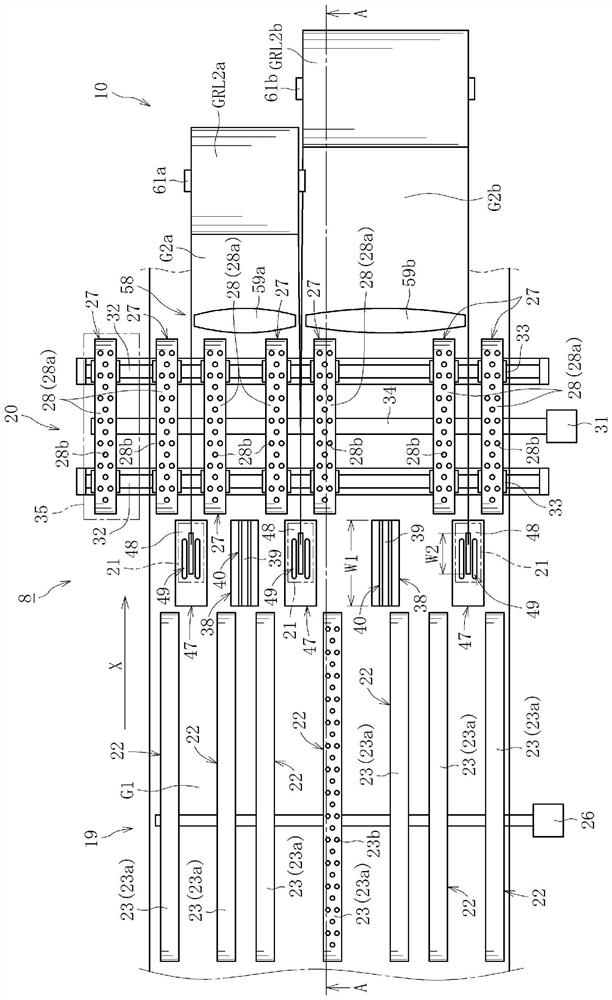

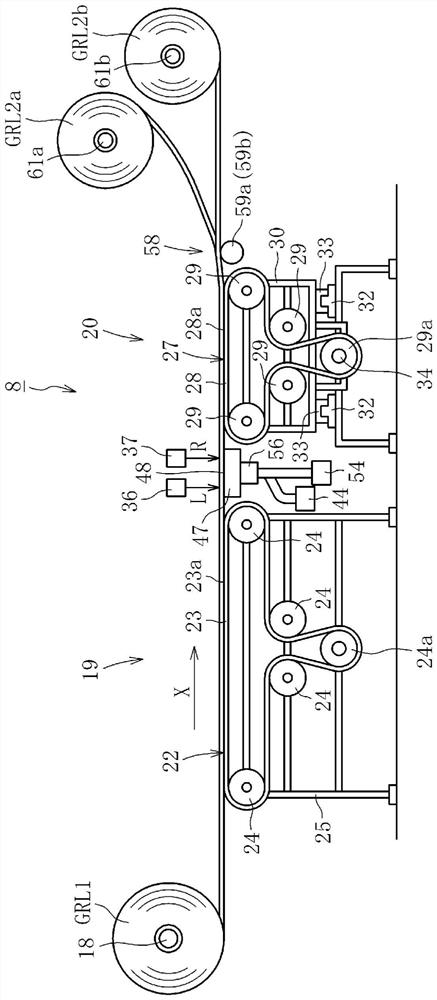

[0054] Below, based on Figure 1 to Figure 10 The 1st Embodiment of the manufacturing method of the glass film of this invention is demonstrated.

[0055] like figure 1 As shown, the manufacturing apparatus 1 of the glass film according to the first embodiment of the present invention includes: a forming part 2 that forms a strip-shaped base material glass film G; and a direction changing part 3 that changes the advancing direction of the base material glass film G from The longitudinal direction is changed from the bottom to the horizontal direction; the first conveying part 4 conveys the base material glass film G in the transverse direction after the direction change; In the present embodiment, the manufacturing apparatus 1 further includes a second glass film (hereinafter, referred to as a first glass film.) G1 from which both ends in the width direction are removed in a roll shape to obtain a first glass roll GRL1. One winding part 6 can therefore also be used as a manu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com