Rotary kiln device

A rotary kiln and cylinder technology, which is applied in the field of organic solid waste recycling, can solve the problems of toxic gas leakage, jumping or stringing, tightness and looseness of the sealing ring, etc., so as to avoid poor sealing effect and avoid gas leakage. , Improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention is further described below by means of examples, but the present invention is not limited to the scope of the examples.

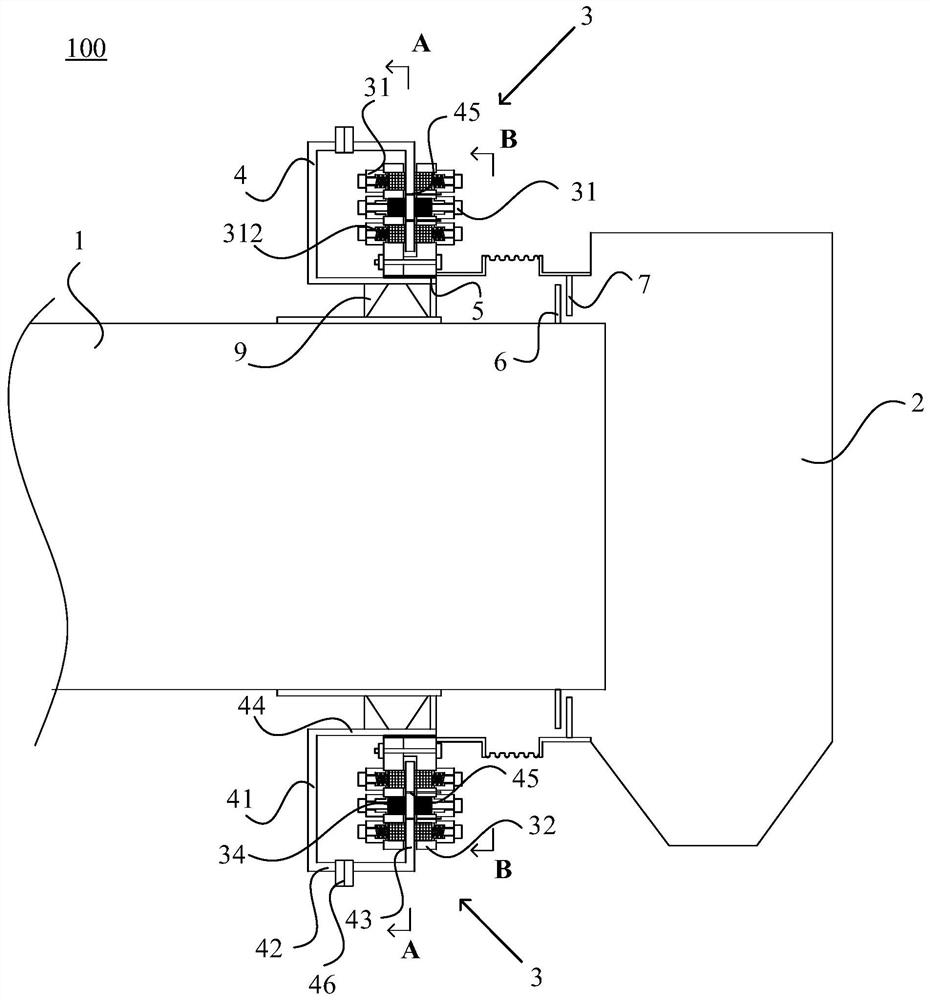

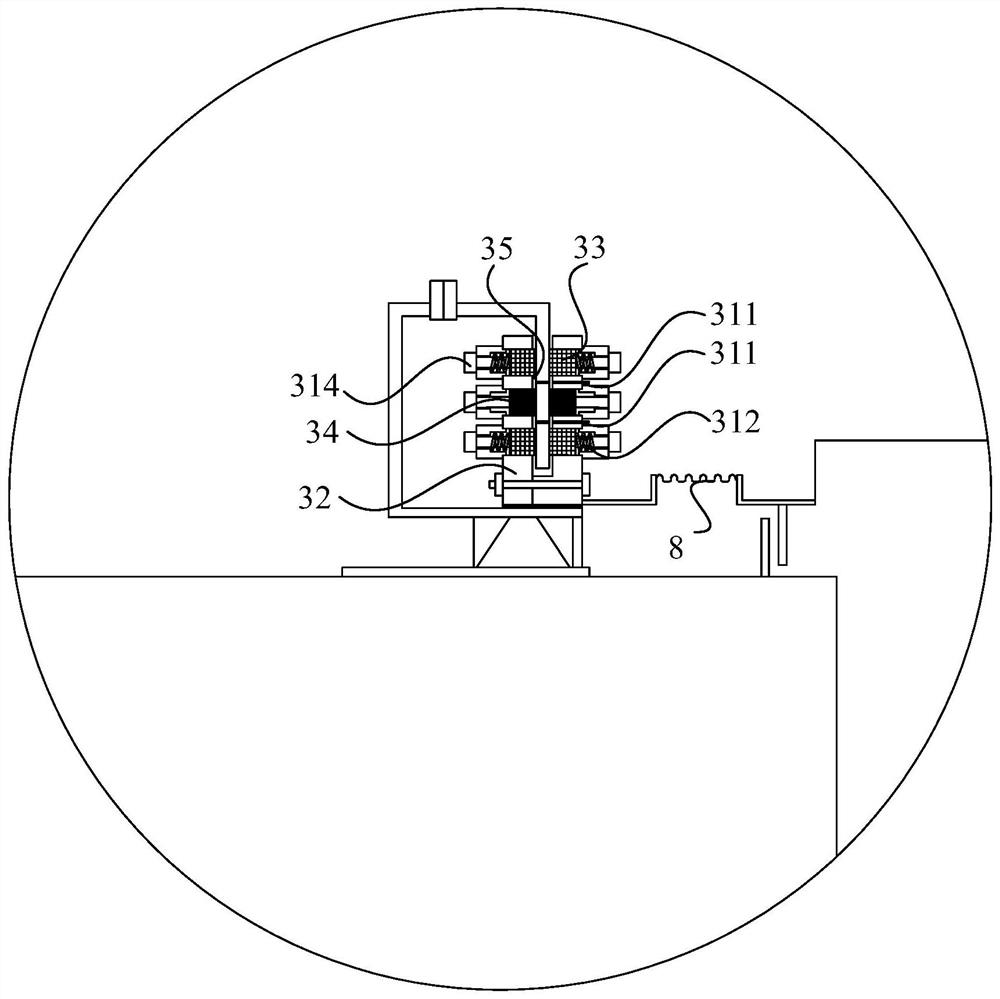

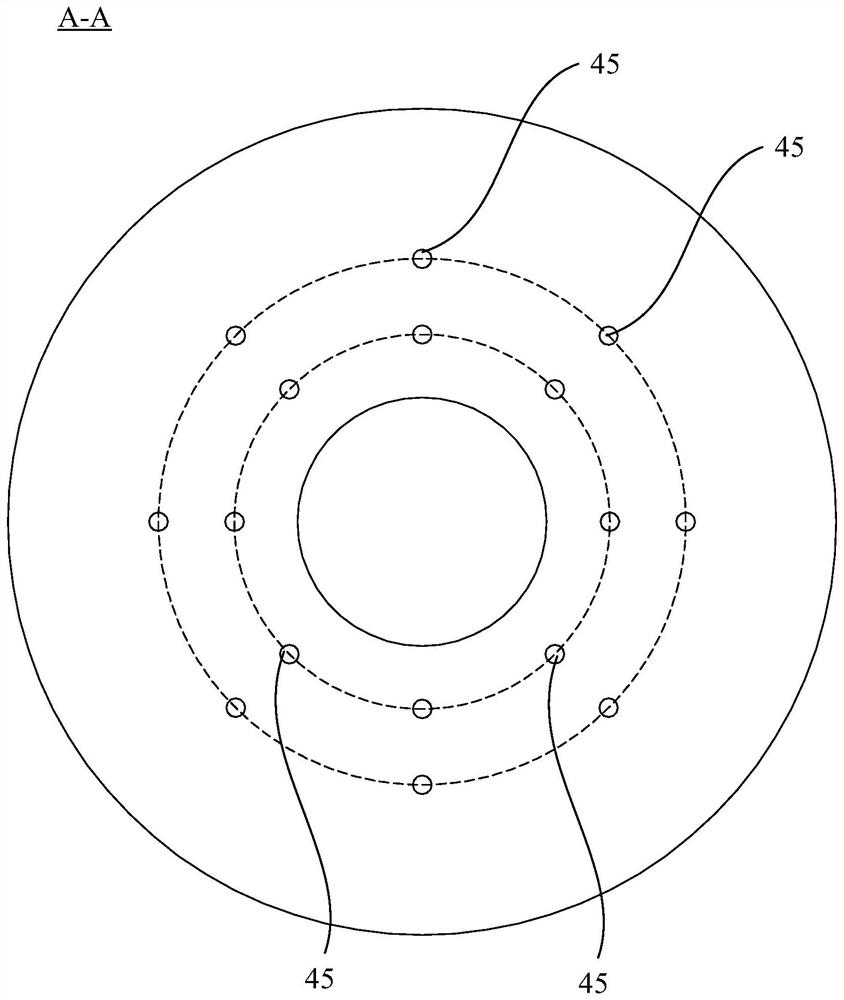

[0069] like Figure 1-Figure 4 As shown, this embodiment provides a rotary kiln device 100. The rotary kiln device 100 includes a cylindrical body 1 and a cover head 2. The cover head 2 is covered at the end of the cylindrical body 1, and the cylindrical body 1 can rotate around a pivot axis. The cover head 2 is fixedly arranged, the cylinder body 1 is communicated with the cover head 2, and the rotary kiln device 100 further includes: a sealing assembly 3, which is fixedly connected to the end of the cover head 2; Connected to the cylinder body 1, the enclosure plate assembly 4 extends radially outward from the outer wall of the cylinder body 1; the seal assembly 3 clamps the enclosure plate assembly 4 from both sides of the enclosure plate assembly 4, and the seal assembly 3 is used to block the cylinder body 1 and hood 2 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com