Electric pump with signal control

An electric pump with signal technology, applied in pump control, rotary piston type/swing piston type pump components, pump components, etc. Avoid poor sealing effect, increase sealing area, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

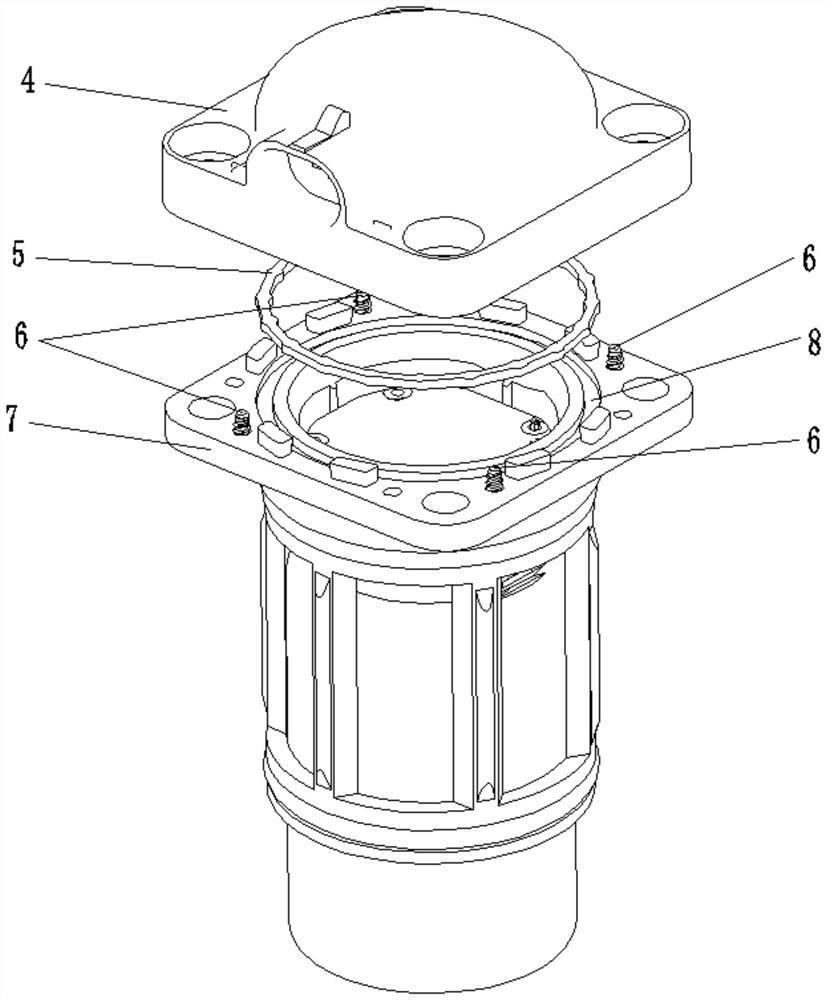

[0033] see Figure 1-5 , the present invention provides a technical solution: an electric pump with signal control, which is characterized in that it includes an upper cover 4 and a pump cover 14, a positioning bracket 15 is provided inside the pump cover 14, and a filter is provided at the bottom of the pump cover 14. Net 19, locating bracket 15 surface is movably connected with spool 16, and spool 16 is connected with filter screen 19 away from an end of locating bracket 15, and the junction of spool 16 and filter screen 19 is movably connected with valve bracket 18, and valve bracket 18 A valve spring 17 is movably connected to the surface, and the end of the valve spring 17 away from the valve bracket 18 is fixedly connected with the valve core 16 .

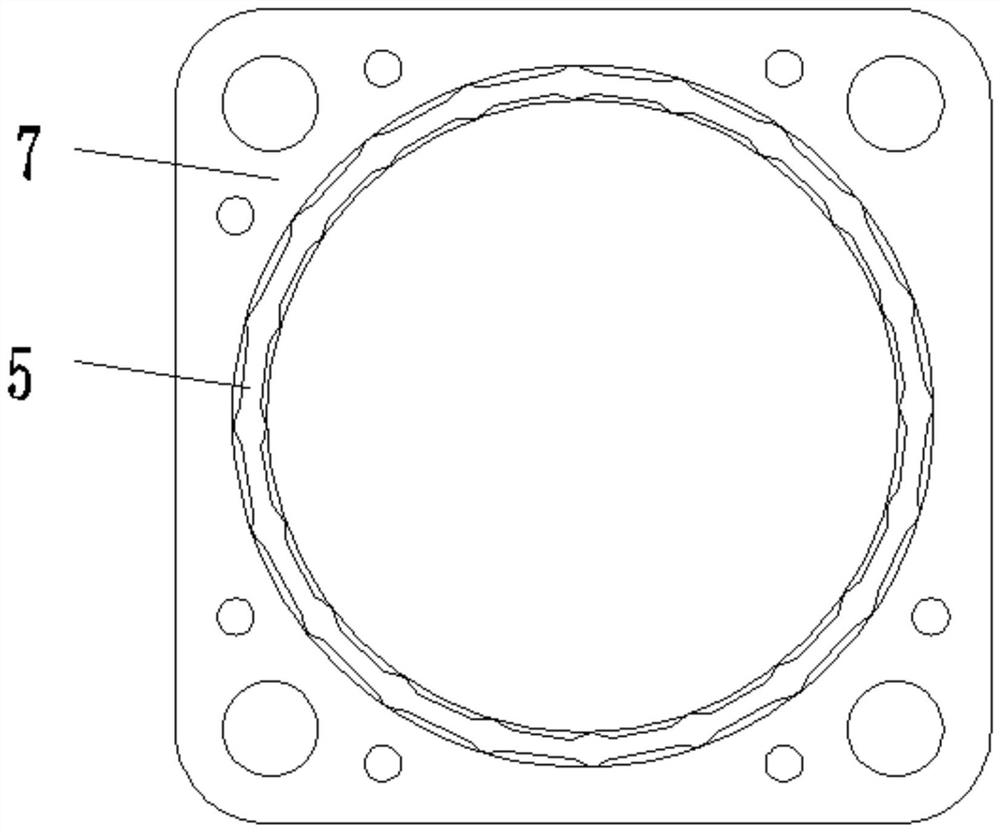

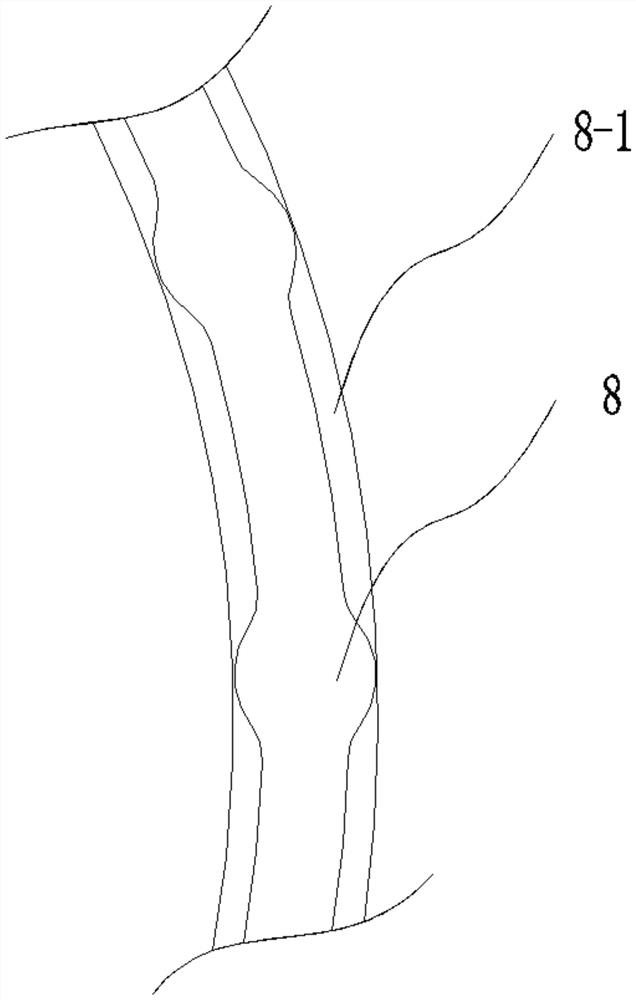

[0034] Further, the bottom of the upper cover 4 is provided with a controller housing 7, the surface of the controller housing 7 is provided with a controller housing groove 8, and the surface of the controller housing groove...

Embodiment 2

[0037] see Figure 1-7 , the present invention provides a technical solution: an electric pump with signal control, which is characterized in that it includes an upper cover 4 and a pump cover 14, a positioning bracket 15 is provided inside the pump cover 14, and a filter is provided at the bottom of the pump cover 14. Net 19, locating bracket 15 surface is movably connected with spool 16, and spool 16 is connected with filter screen 19 away from an end of locating bracket 15, and the junction of spool 16 and filter screen 19 is movably connected with valve bracket 18, and valve bracket 18 A valve spring 17 is movably connected to the surface, and the end of the valve spring 17 away from the valve bracket 18 is fixedly connected with the valve core 16 .

[0038] Further, the inner left and right side walls of the controller housing 7 are fixedly connected with the whole body 11, and the upper and lower sides of the whole body 11 are fixedly connected with the upper and lower i...

Embodiment 3

[0041] see Figure 1-10 , the present invention provides a technical solution: an electric pump with signal control, which is characterized in that it includes an upper cover 4 and a pump cover 14, a controller housing 7 is arranged at the bottom of the upper cover 4, and the controller housing 7 The inner left and right side walls are fixedly connected with the whole body 11, and the upper and lower sides of the whole body 11 are fixedly connected with the upper and lower insulating protective sleeves 10, and the upper and lower insulating protective sleeves 10 are provided with positioning grooves on the surface, and the surface of the positioning grooves is provided with rectangular clamping rods 9 A controller 13 is fixedly connected to the side of the rectangular clamping rod 9 away from the upper and lower insulating protective sleeves 10, and a sealant 12 is fixedly connected to the joint between the controller 13 and the rectangular clamping rod 9; this part is a self-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com