Garment processing device with rapid drying function

A technology of fast drying and processing equipment, applied in the direction of heating equipment, drying, dryers, etc., can solve the problems of slow drying speed and low efficiency of clothing, achieve fast speed, improve drying efficiency, and prevent horizontal shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

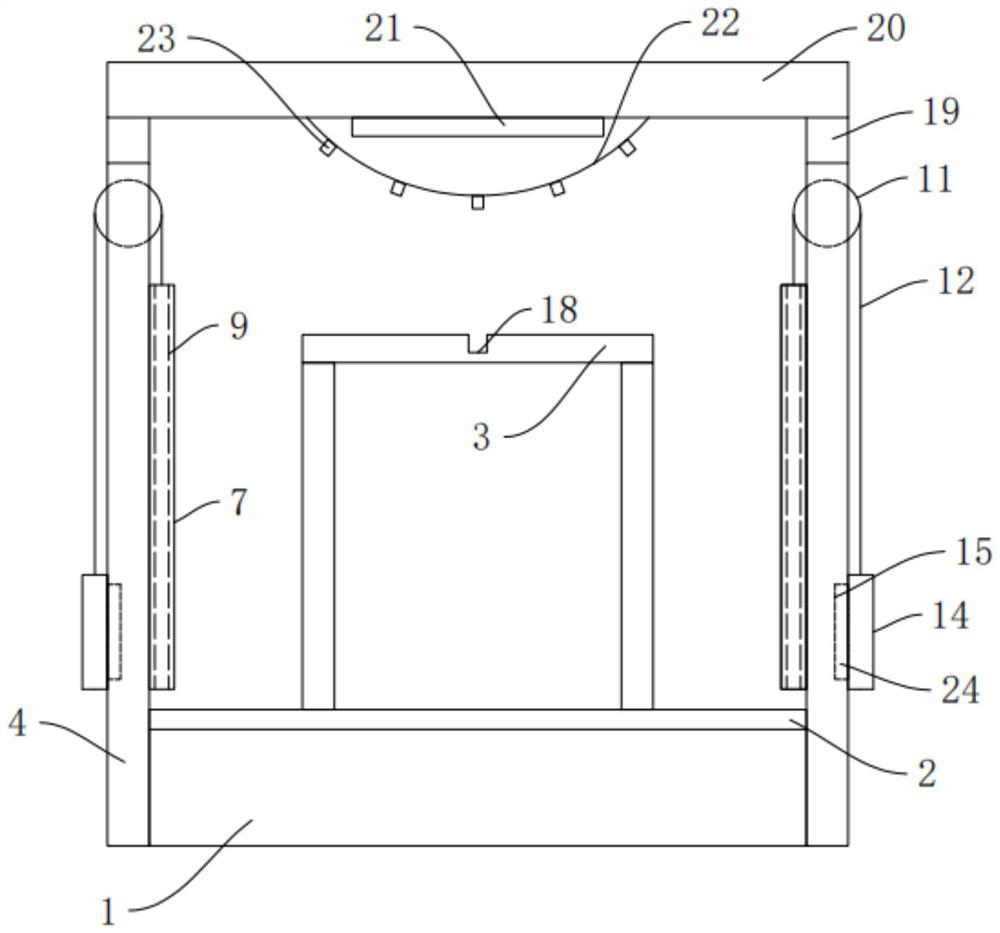

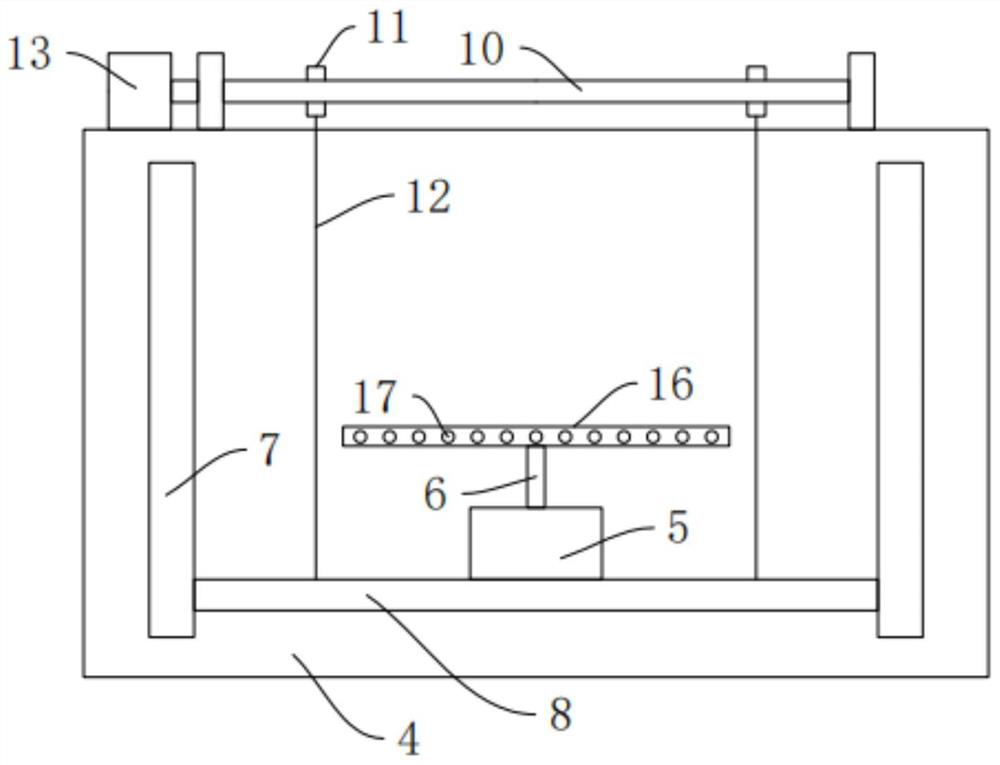

[0032] refer to Figure 1-2, the present invention provides a garment processing device with a fast drying function, comprising: a base 1, on which a conveyor belt 2 is arranged, and a hanger 3 is arranged on the conveyor belt 2, and the hanger 3 is used for hanging garments The support plate 4 is connected with the base 1, and the support plate 4 is provided with an air heater 5 and a warm air duct 6 communicated with the air heater 5, and the warm air duct 6 is used for the The clothes on the hanger 3 blow air; a driving device, which is connected with the support plate 4, is used to drive the heater 5 and the heater 6 to move in the vertical direction; a limit device, which is connected with the support The plate 4 is connected to limit the displacement of the warm air duct 6 in the horizontal direction.

[0033] Through the above settings, when the clothes need to be dried, the operator hangs the clothes to be dried on the hanger 3, and then starts the conveyor belt 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com