Method for enhancing red mud dealkalization absorption of SO2 by using MgCl2 and utilizing ore pulp

A technology of SO2 and dealkalization, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve problems such as difficult large-scale application, no waste utilization, and single purpose, so as to control emissions, improve utilization, Effect of reducing environmental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

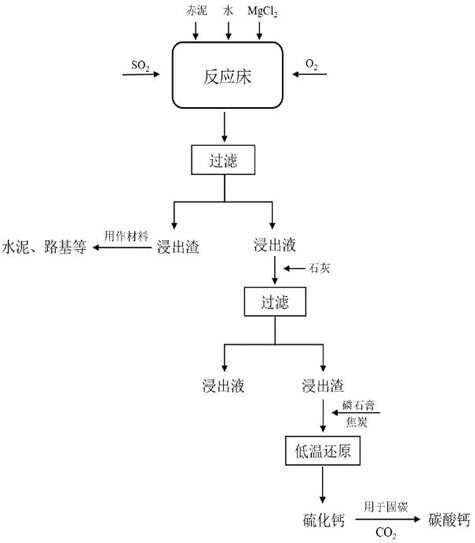

[0050] Utilize MgCl 2 Enhanced red mud dealkalization to absorb SO 2 And the method for utilizing the pulp includes the following steps:

[0051] S1, the red mud is pulverized, ground, passed through a 100-mesh sieve, and then transferred to the reaction bed, and water is added to stir for slurrying, and MgCl is added during the stirring process. 2 solution, the dealkalization time is 30min, the liquid-solid ratio of water and red mud is 18mL:1g, MgCl 2 The concentration is controlled at 0.04mol / L, and the temperature of the dealkalization process is controlled at 170℃;

[0052] S2. After the red mud is dealkalized, the reaction bed is fed with SO 2 At the same time, aeration and oxidation are carried out. During the desulfurization period, continuous stirring is carried out. The desulfurization time is 2h. 2 of smoke and aerated O 2 The volume ratio is 1:15, and the passage contains SO 2 The flow rate of the flue gas is 35mL / min, and the desulfurization temperature is c...

Embodiment 2

[0055] Utilize MgCl 2 Enhanced red mud dealkalization to absorb SO 2 And the method for utilizing the pulp includes the following steps:

[0056] S1, the red mud is pulverized, ground, passed through a 100-mesh sieve, and then transferred to the reaction bed, and water is added to stir for slurrying, and MgCl is added during the stirring process. 2 Solution, dealkalization time 60min, liquid-solid ratio of water and red mud is 22mL:1g, MgCl 2 The concentration is controlled at 0.06mol / L, and the temperature of the dealkalization process is controlled at 190℃;

[0057] S2. After the red mud is dealkalized, the reaction bed is fed with SO 2 At the same time, aeration and oxidation are carried out, and continuous stirring is carried out during the desulfurization period. The desulfurization time is 4h. 2 of smoke and aerated O 2 The volume ratio is 1: 25, and the feed contains SO 2 The flow rate of the flue gas is 50mL / min, and the desulfurization temperature is controlled ...

Embodiment 3

[0060] Utilize MgCl 2 Enhanced red mud dealkalization to absorb SO 2 And the method for utilizing the pulp includes the following steps:

[0061] S1, the red mud is pulverized, ground, passed through a 100-mesh sieve, and then transferred to the reaction bed, and water is added to stir for slurrying, and MgCl is added during the stirring process. 2 The solution, the dealkalization time is 45min, the liquid-solid ratio of water and red mud is 20mL:1g, MgCl 2 Its concentration is controlled at 0.05mol / L, and the temperature of the dealkalization process is controlled at 180℃;

[0062] S2. After the red mud is dealkalized, the reaction bed is fed with SO 2 At the same time, aeration and oxidation are carried out, and continuous stirring is carried out during the desulfurization period. The desulfurization time is 3h. 2 of smoke and aerated O 2 The volume ratio is 1:20, and the passage contains SO 2 The flow rate of the flue gas is 42.5mL / min, and the desulfurization tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com