Anti-adhesion membrane for promoting nerve repair and preparation method thereof

An anti-adhesion film and nerve repair technology, which is applied in the field of medical materials, can solve the problems of different anti-adhesion film matching, anti-adhesion film hardening and brittleness, etc., to achieve wound healing, prevent adhesion, and simple and easy preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a preparation method for promoting nerve repairing anti-adhesion film, comprising the following steps:

[0038] a) dissolving the degradable polymer and the drug in the organic solvent A to obtain a precursor solution;

[0039] or

[0040] Dissolving the degradable polymer-drug conjugate in organic solvent A to obtain a precursor solution;

[0041] b) coating the precursor solution on the bottom plate to form a film, and forming a wet film on the bottom plate;

[0042] c) immersing the bottom plate with wet film obtained in step b) in solvent B to remove organic solvent A, and drying to obtain an anti-adhesion film;

[0043] in:

[0044] The organic solvent A is selected from one or more of N,N-dimethylformamide, N,N-dimethylacetamide, N-methylpyrrolidone and 1,4-dioxane;

[0045] Described solvent B is water, or is the mixture of water and organic solvent A;

[0046] The drug is a drug for promoting nerve repair.

[0047]In the preparation ...

Embodiment 1

[0072] 1. Preparation

[0073] Weigh 0.5g of PLGA-PEG copolymer (the number average molecular weight is 100,000, and the mass ratio of PEG structural fragments is 5%) and 25mg of drug RAPA were dissolved in 2mL of N,N-dimethylacetamide, and stirred evenly After that, the precursor solution was obtained. Set the parameters of the flat film scraper: the film thickness is 0.05mm, and the blade speed is 1m / min. Pour the above precursor solution on the glass plate and turn on the equipment to scrape the film, then quickly immerse the glass plate in excess deionized water, replace the deionized water after half an hour, and repeat the above operation until the organic solvent in the anti-adhesion film is completely removed . Finally, the formed film was taken out from the glass plate and dried at room temperature to obtain a drug-loaded anti-adhesion film.

[0074] 2. Characterization

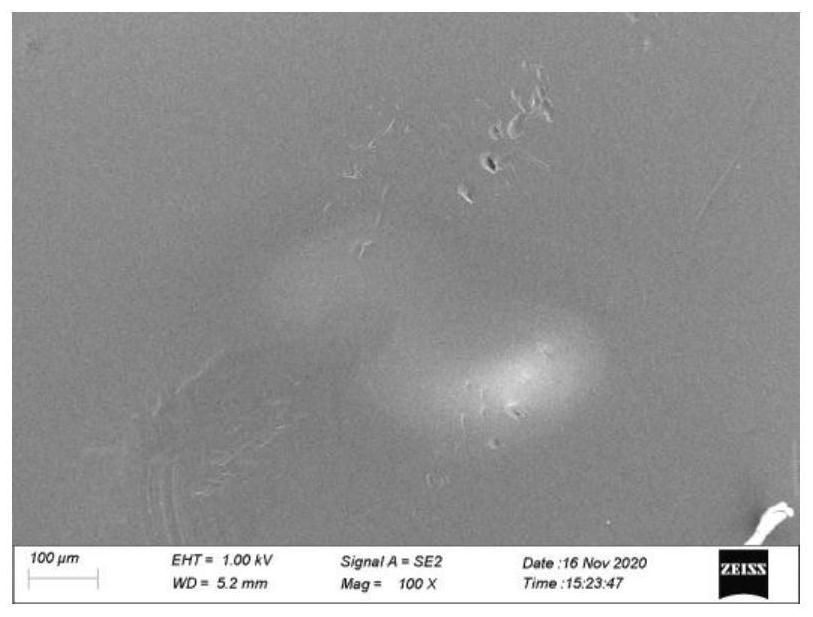

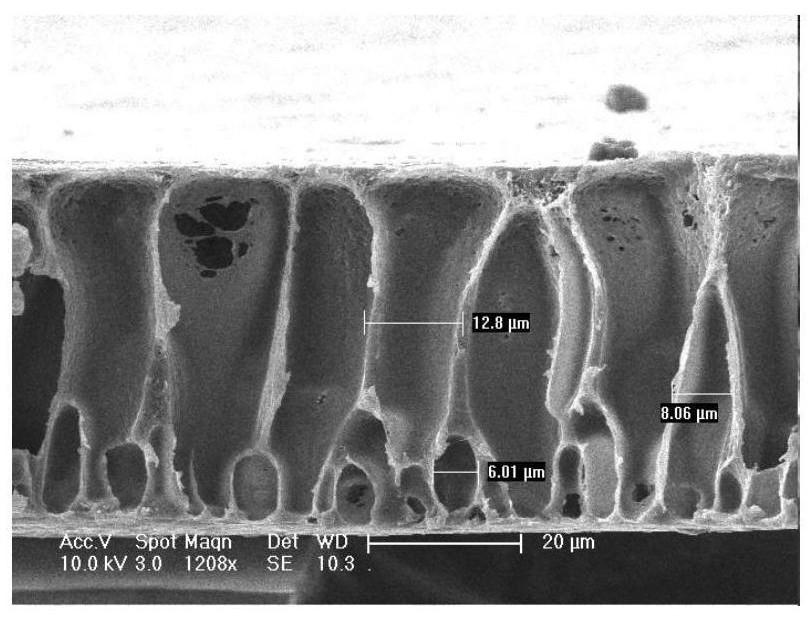

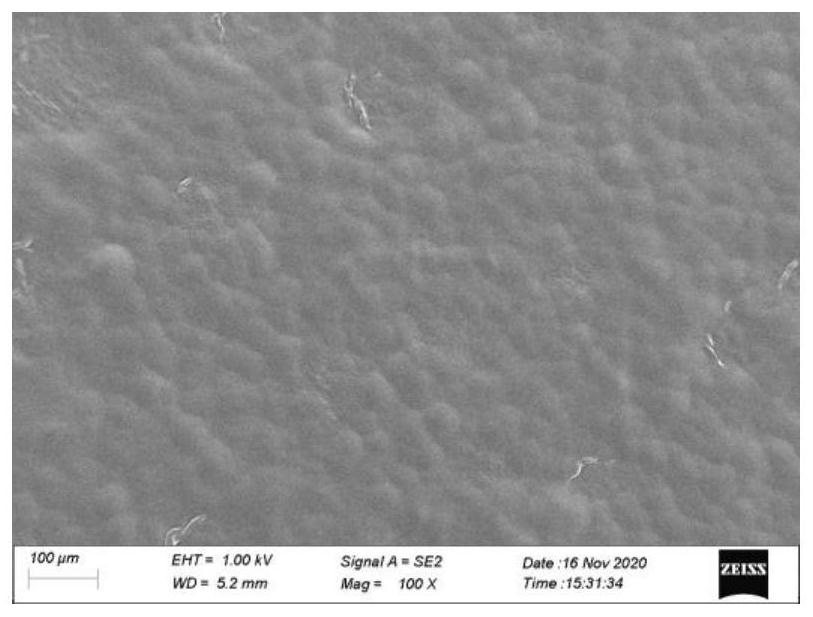

[0075] Scanning electron microscope (SEM) observation was performed on the upper surface, cro...

Embodiment 2

[0089] 1. Preparation

[0090] Weigh 0.002g of PLA-PEG copolymer (the number average molecular weight is 250,000, and the mass ratio of PEG structural fragments is 10%) and 400mg of drug RAPA were dissolved in 2mL of N,N-dimethylacetamide and 1,4 - in a mixed solvent of dioxane (volume ratio of 1:3), after stirring uniformly, a precursor solution is obtained. Set the parameters of the flat film scraper: the film thickness is 1mm, and the blade speed is 0.1m / min. Pour the above precursor solution on the glass plate and turn on the equipment to scrape the film, then quickly immerse the glass plate in excess deionized water, replace the deionized water after half an hour, and repeat the above operation until the organic solvent in the anti-adhesion film is completely removed . Finally, the formed film was taken out from the glass plate and dried at room temperature to obtain a drug-loaded anti-adhesion film.

[0091] 2. Characterization

[0092] According to the characterizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com