Impeller assembly for low-loss centrifugal fan and fan thereof

A centrifugal fan and low-loss technology, applied to machines/engines, components of pumping devices for elastic fluids, pump components, etc., can solve problems such as easy to generate loud noise, stability impact, equipment vibration, etc., to achieve Good thermal deformation resistance, reduced flow resistance, and the effect of suppressing turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

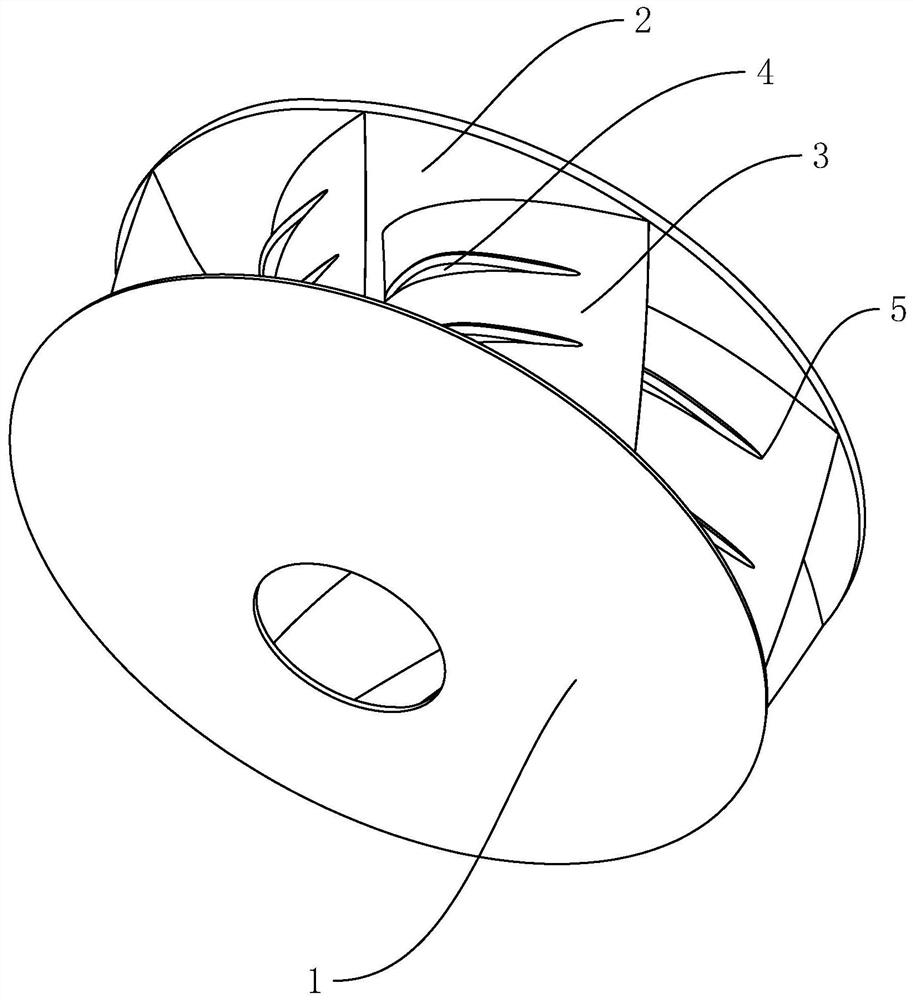

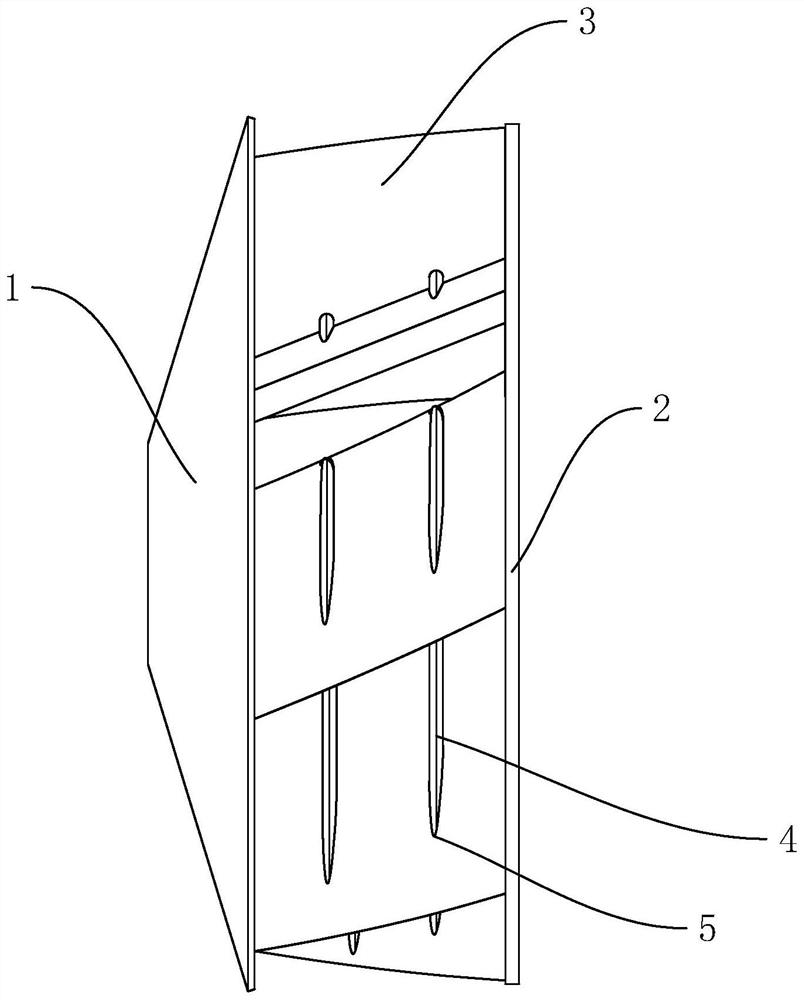

[0037]Embodiment 1: An impeller assembly for a low-loss centrifugal fan, comprising a front cover 1, a rear cover 2, and a plurality of backward blades 3 located between the front cover 1 and the rear cover 2, and the plurality of backward blades 3 are The annular array is distributed between the front cover plate 1 and the rear cover plate 2, and the end of the rearward blade 3 facing the center of the annular array of the plurality of rearward blades 3 is provided with an arc portion 6, and the arc-shaped concave surface of the arc portion 6 faces the edge of the rearward blade 3. The rearward vane 3 is arranged in the direction of the end, and the array center of the rearward vane 3 is concentric with the front cover 1 and the rear cover 2. The rearward vane 3 is an arc structure. The fins 4 are arranged in the arc length direction of the blade 3. The fins 4 are used to suppress turbulent bursts. In this embodiment, the front cover 1, the rear cover 2 and the rearward blade ...

Embodiment 2

[0041] Embodiment 2: a low-loss centrifugal fan, further comprising a volute for accommodating the impeller assembly, the volute is provided with an air inlet and an air outlet 7, and the guide baffle 13 located at the air outlet 7 is fixedly connected in the volute , the guide baffle 13 is obliquely arranged on the air outlet 7 so that the diameter of the air outlet 7 gradually decreases, the guide baffle 13 and the inner wall of the volute are filled with sound-absorbing filling particles, and the volute is detachably connected to the air inlet. The current collector 8 has a hollow trumpet-shaped structure, and an elastic flange 9 is formed at one end of the current collector 8 located in the volute. It is arranged coaxially with the inlet of the front cover 1, and a buffer assembly is provided between the collector 8 and the inner wall of the volute. A cone-shaped structure, the end of the support portion 10 facing the front cover 1 is provided with a ring portion 12 that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com