Amorphous alloy strip surface cleaning method and amorphous alloy strip

A technology for the surface of amorphous alloys and strips, which is applied in the direction of building components, slender components, etc., can solve the problems such as the influence of coating coating process, achieve good cleaning effect and enhance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

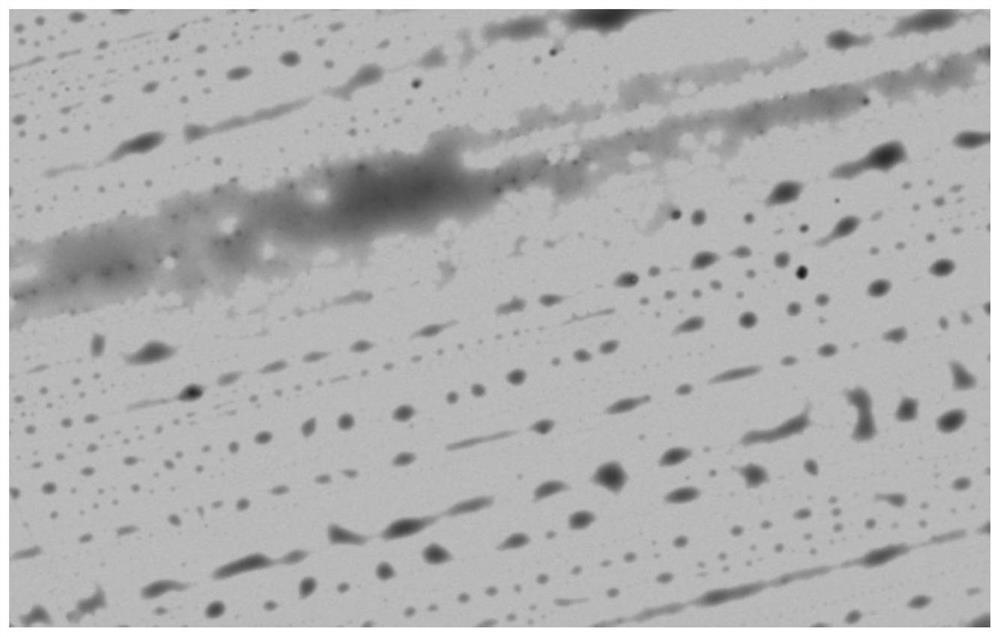

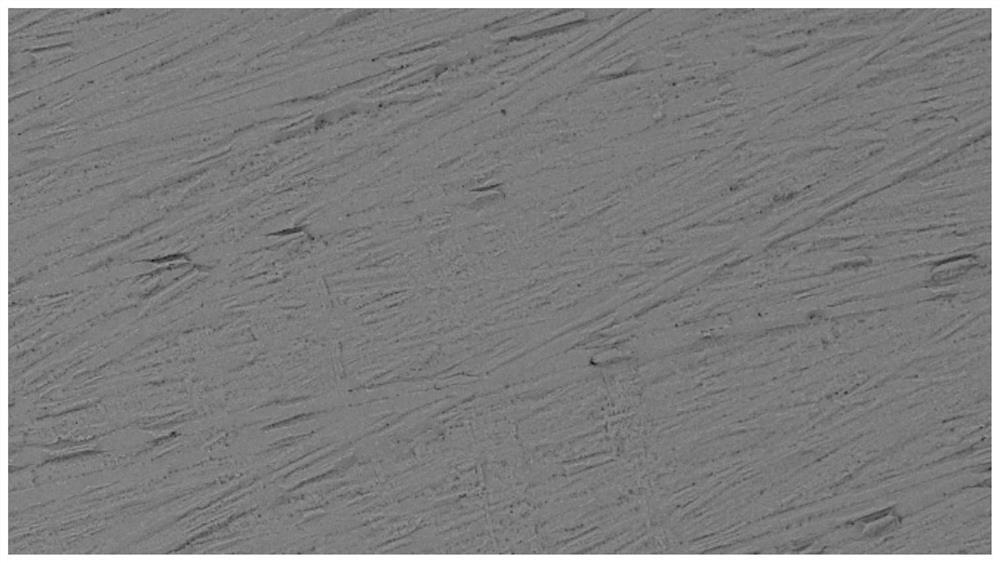

[0045] In this embodiment, the Fe-based amorphous alloy strips rolled to a width of 40 mm are cleaned by the above cleaning method. The cleaning process is set as: alkaline washing -> water washing -> alcohol washing. The alkaline washing solution adopts NaOH solution, the pH value is 8, and 5% surfactant is added to the alkaline washing solution to accelerate the removal of oil stains. The cleaning process adopts ultrasonic cleaning. The surface morphology of the amorphous alloy strip before and after cleaning was compared by SEM observation, such as figure 2 , 3 As shown in the figure, there is a lot of dirt on the surface of the strip that has not been cleaned. In the black dots in the figure, the surface of the cleaned amorphous alloy strip is clean and free of dirt.

Embodiment 2

[0047] In this example, the Fe-based amorphous alloy strip cleaned in Example 1 is cleaned twice, and the cleaning process is: pickling->water-washing->alcohol-washing. The pickling solution is a phosphoric acid solution with a pH value of 6. Use a micrometer to measure the difference between the thickness of the strip at the pitted position and the position without pitting, and the height of the pitting can be calculated. Before pickling, the pit height was 1.5 μm, and after pickling, the pit height was 0.5 μm, indicating that the sharp corners of the pits were obtuse. The obtuse pitting will prevent the subsequent coating from causing discontinuity of the coating due to sharp protrusions, and improve the insulating ability, as shown in Table 1 (testing 100 points).

[0048] Table 1 Number of coating insulation points before and after pickling

[0049] Coating before pickling Coating after pickling Number of insulation points 8 20

Embodiment 3

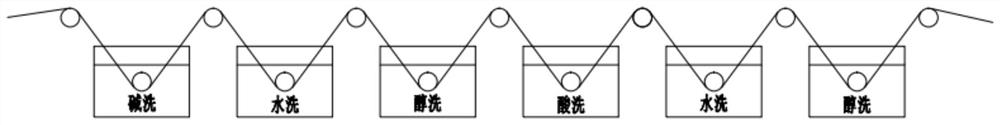

[0051] This example compares the effect of ultra-thin coating on Fe-based amorphous alloy strips before and after cleaning. The Fe-based amorphous alloy strip was 16 μm thick and was roll cut into strips with a width of 40 mm. The cleaning process selection is: alkaline washing -> water washing -> alcohol washing -> acid washing -> water washing -> alcohol washing. Among them, the alkaline washing solution is a NaOH solution with a pH value of 8, and 5% of surfactant is added, and the constant temperature of the alkaline washing solution is 50°C. The pickling solution is a phosphoric acid solution with a pH of 6, and the constant temperature is 20°C. The water washing solution was deionized water at a temperature of 20°C. The alcohol washing solution adopts ethanol, and the temperature is 20 ℃. All cleaning procedures are carried out by ultrasonic cleaning.

[0052] The cleaned and uncleaned rolling shear belts are respectively coated with the equipment described in the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com