Corrugated board processing technology

A corrugated board and processing technology, applied in the field of corrugated paper processing, can solve the problems of increasing tearing, lack of self-repairing effect, loss of content protection effect, etc., and achieve the effect of improving buffer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

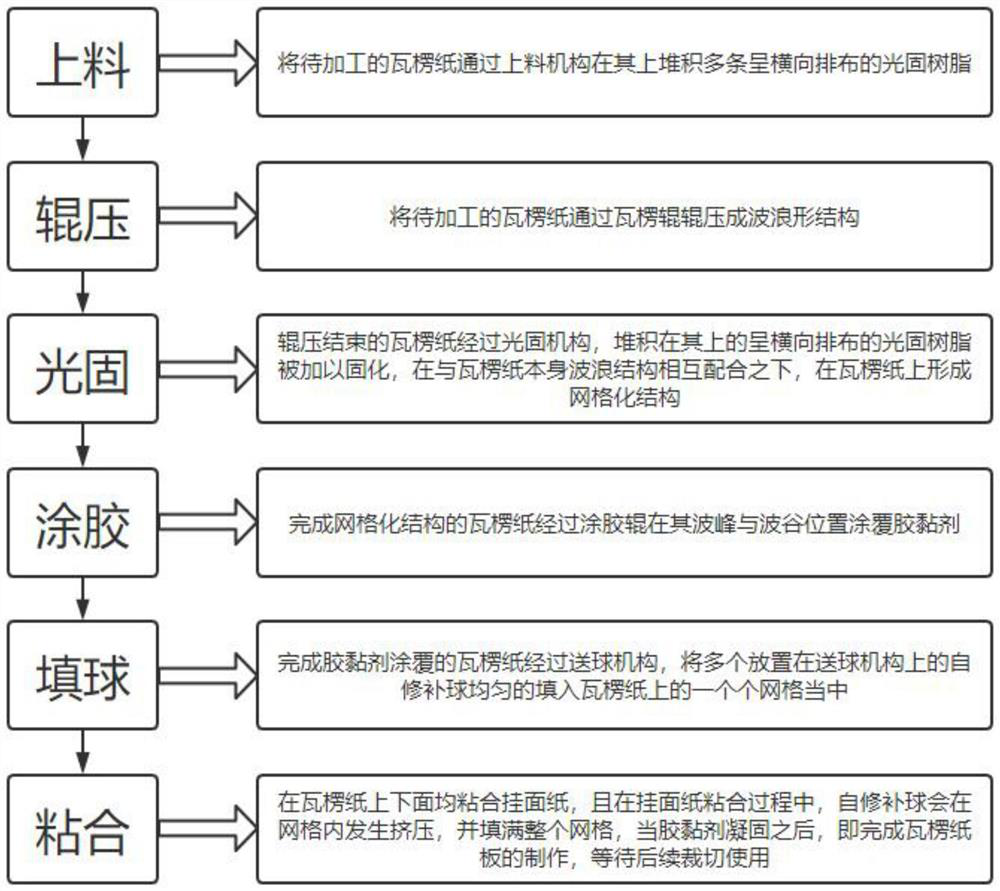

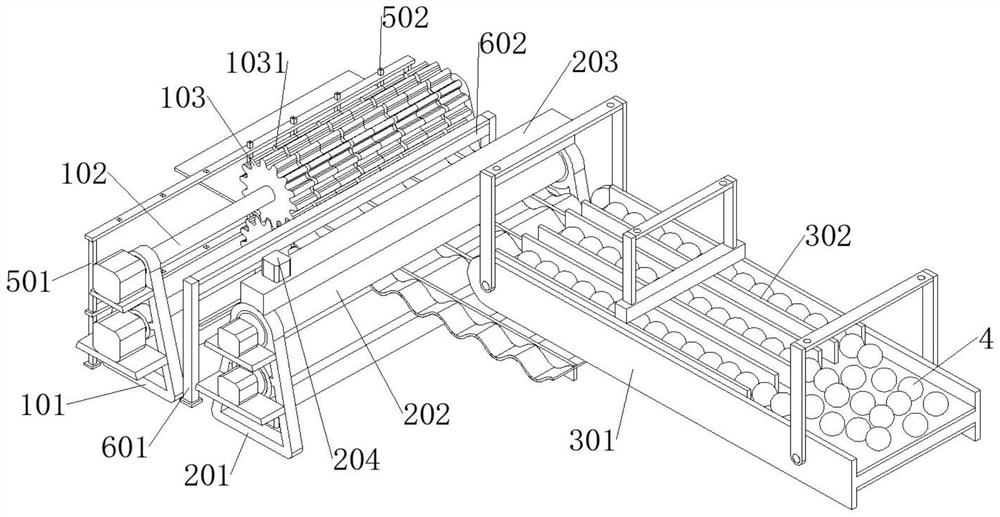

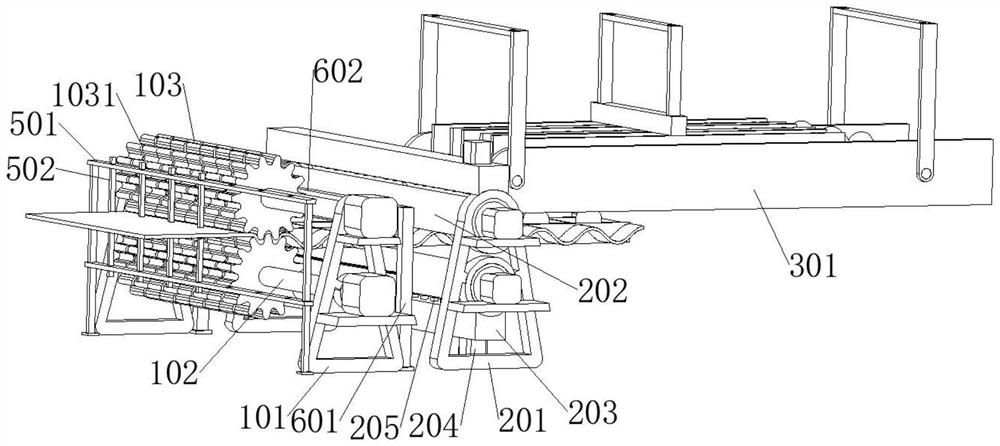

[0051] see Figure 1-4 , a corrugated cardboard processing technology, comprising the following steps:

[0052] S1. Feeding: The corrugated paper to be processed is stacked on it through the feeding mechanism, and a plurality of light-curing resins arranged horizontally;

[0053] S2. Rolling: the corrugated paper to be processed is rolled into a wave-shaped structure through a corrugating roller;

[0054] S3. Light-curing: The corrugated paper after rolling passes through the light-curing mechanism, and the light-curing resin deposited on it in a horizontal arrangement is cured. Under the cooperation with the corrugated paper itself, a grid is formed on the corrugated paper. structure;

[0055] S4. Gluing: The corrugated paper with the grid structure is coated with adhesive at the crests and troughs of the corrugated paper through the gluing roller;

[0056] S5. Ball filling: The corrugated paper coated with the adhesive passes through the ball feeding mechanism, and a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com