Full-automatic coal mine washing treatment equipment

A processing equipment, fully automatic technology, applied in the direction of solid separation, liquid cleaning method, cleaning method and utensils, etc., can solve the problems of auxiliary push, coal fragmentation, inability to buffer the impact force of falling, etc., and achieve good turning effect , to avoid direct drop, to avoid the effect of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

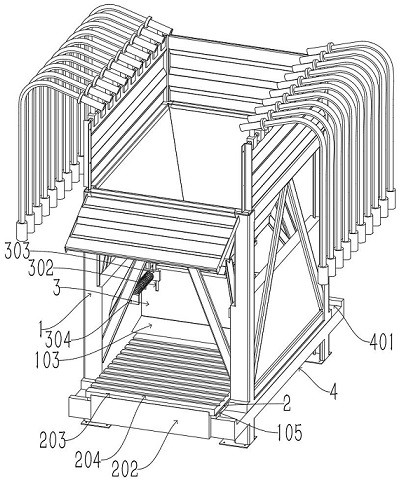

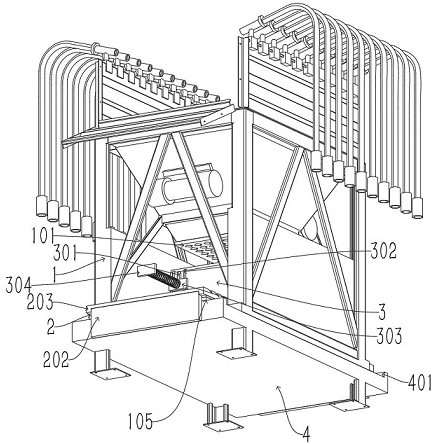

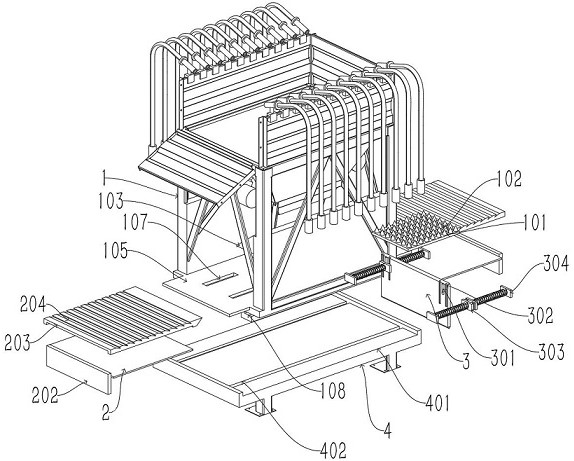

[0029] as attached figure 1 to the attached Figure 8 shown:

[0030] The invention provides a fully automatic coal mine washing and processing equipment, comprising: The main body 1; the main body 1 is a rectangular structure, and the top of the main body 1 is a rectangular funnel-shaped structure, the top of the main body 1 is fixed with cleaning nozzles on both sides, and two vibration motors are installed on both sides of the main body 1. The main body 1 plays a role in receiving vibration. Motor power, and then swing left and right to screen coal blocks, two moving plates 2 are installed on both sides of the bottom of the main body 1, a flip plate 3 is installed in the inner middle of the main body 1, and the bottom of the main body 1 is connected with the top of the bottom piece 4; 2. The moving plate 2 includes a buffer mechanism, the top of the moving plate 2 is equipped with a buffer mechanism, the moving plate 2 is a rectangular plate-like structure, and the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com