Device for driving a compressor and method for producing such a device

A technology for compressors and electric motors, applied in the field of devices for driving compressors, can solve problems such as large installation space of motors, and achieve the effects of increasing insulation resistance, reducing insufficient insulation resistance, and reducing occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

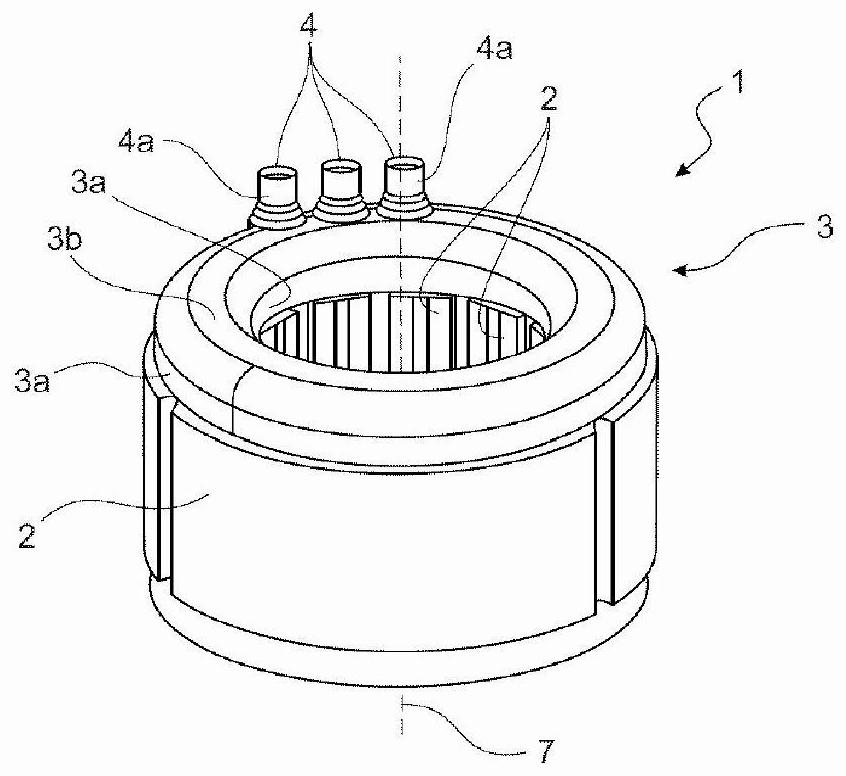

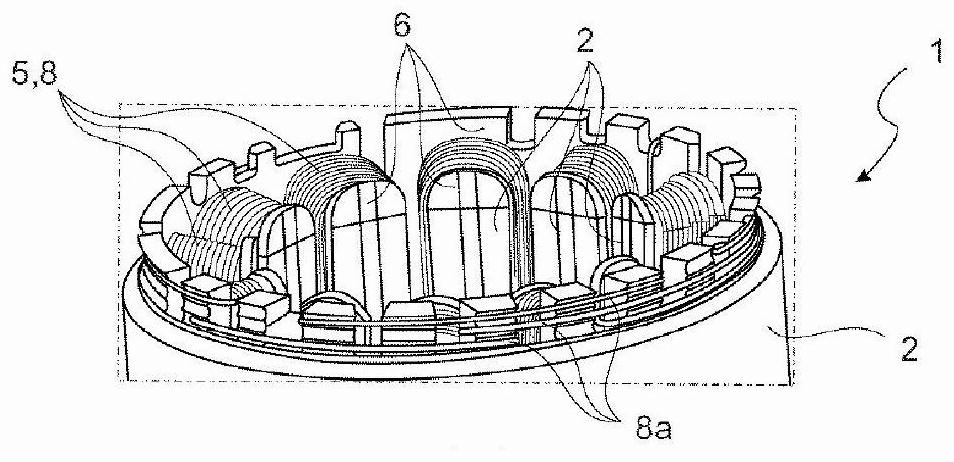

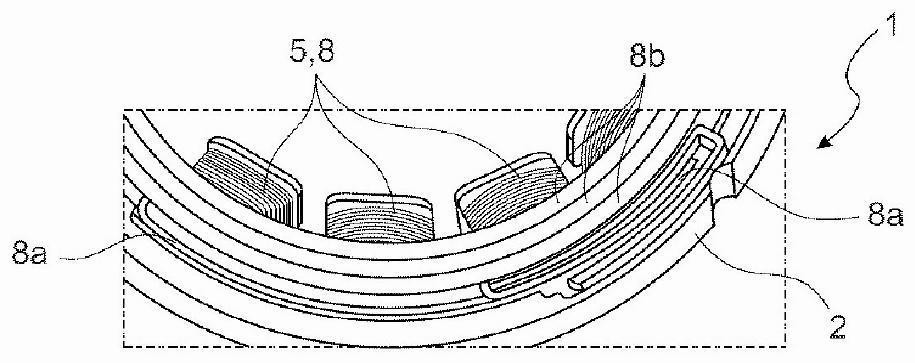

[0057] Figure 1a A stator 1 of an electric motor is shown in a perspective view as a device for driving a compressor of gaseous fluid for conveying refrigerant through a refrigerant circuit, which compressor is used exclusively in motor vehicle air conditioning systems. The stator 1 is shown in a perspective representation with a stator core 2 and a cover element 3 which is arranged on a first end face of the stator 1 and is fitted with a mounting element 4 for mounting a plug-in connector. Figure 1b and Figure 1c are detailed views of the first end face of the stator 1 with coils 5 arranged on the stator core 2 and without cover elements, each shown in a perspective view, while Figure 1d Shown in cross-section with cover element 3 Figure 1a Detail of stator 1 in .

[0058] An electric motor, eg an AC motor with three phases, has a rotor, not shown, and a stator core 2, which is arranged in radial direction on the outer surface of the rotor and thus surrounds the rotor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com