Transverse sweeping type drilling and grinding mountain mining machine

A mining machine and drilling and grinding technology, applied in the field of sweeping drilling and grinding mountain mining machines, can solve the problems of increased resource consumption and loss, high mining risk pollution, high resource consumption rate, etc., to reduce pollution, reduce environmental pollution, The effect of avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

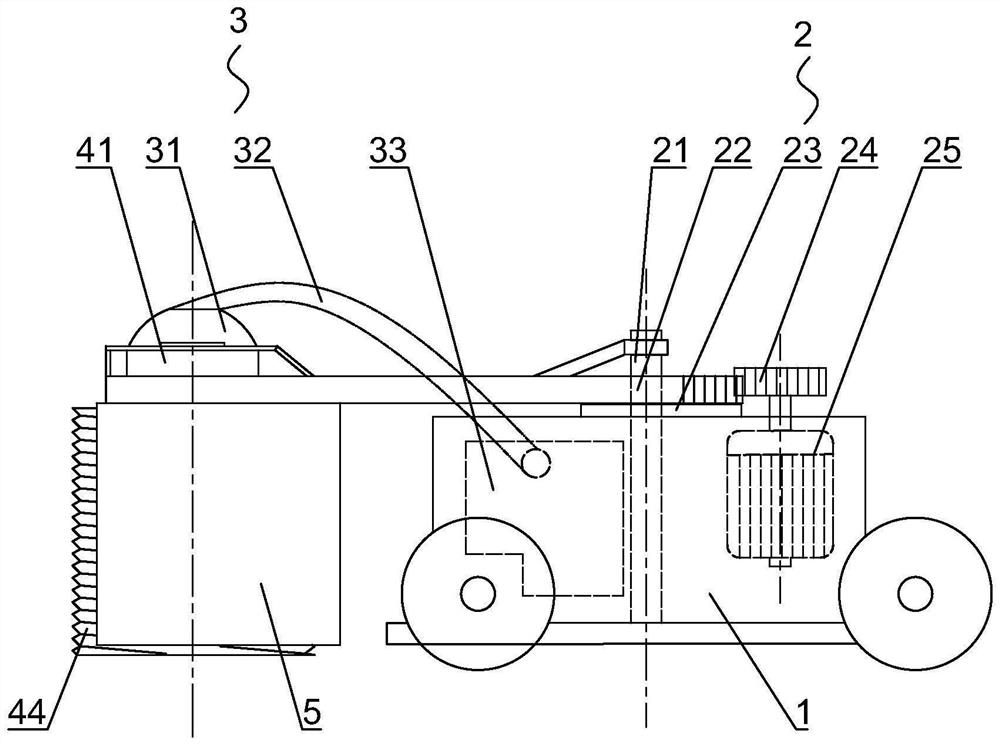

[0033] A sweeping type drilling and grinding mountain mining machine, comprising a vehicle body 1, a swing arm system 2, a dust suction system 3, a drill bit 4, and a shroud 5; wherein:

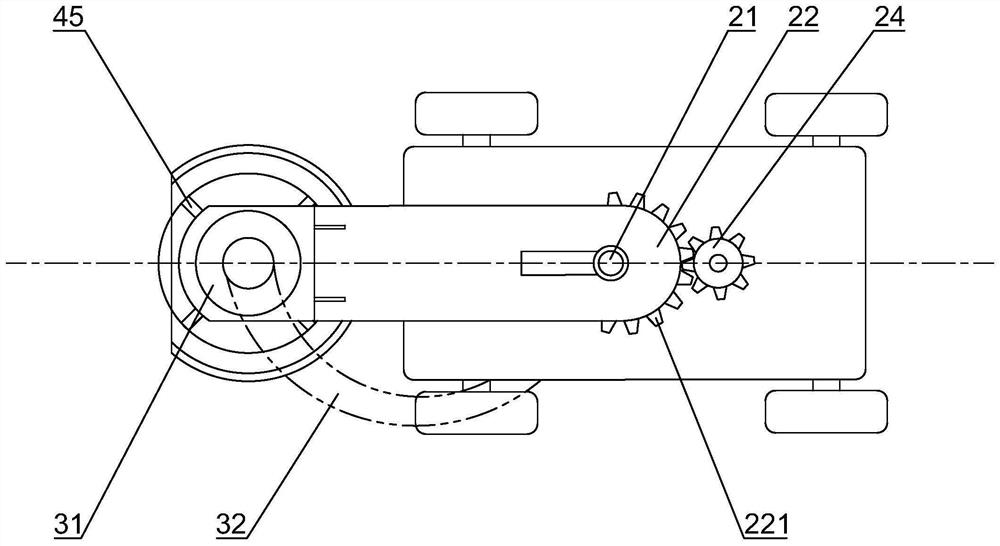

[0034] The swing arm system 2 includes a central shaft 21 , a rigid support arm 22 , a support arm gear 221 , a thrust bearing 23 , a transmission gear 24 , and a steering engine 25 . The rigid support arm 22 is fixedly installed on the central axis, the support arm gear 221 meshes with the transmission gear 24 , and the thrust bearing 23 is installed under the rigid support arm 22 . Driven by the steering engine 25, the rigid support arm 22 is driven by the thrust bearing 23 for steering.

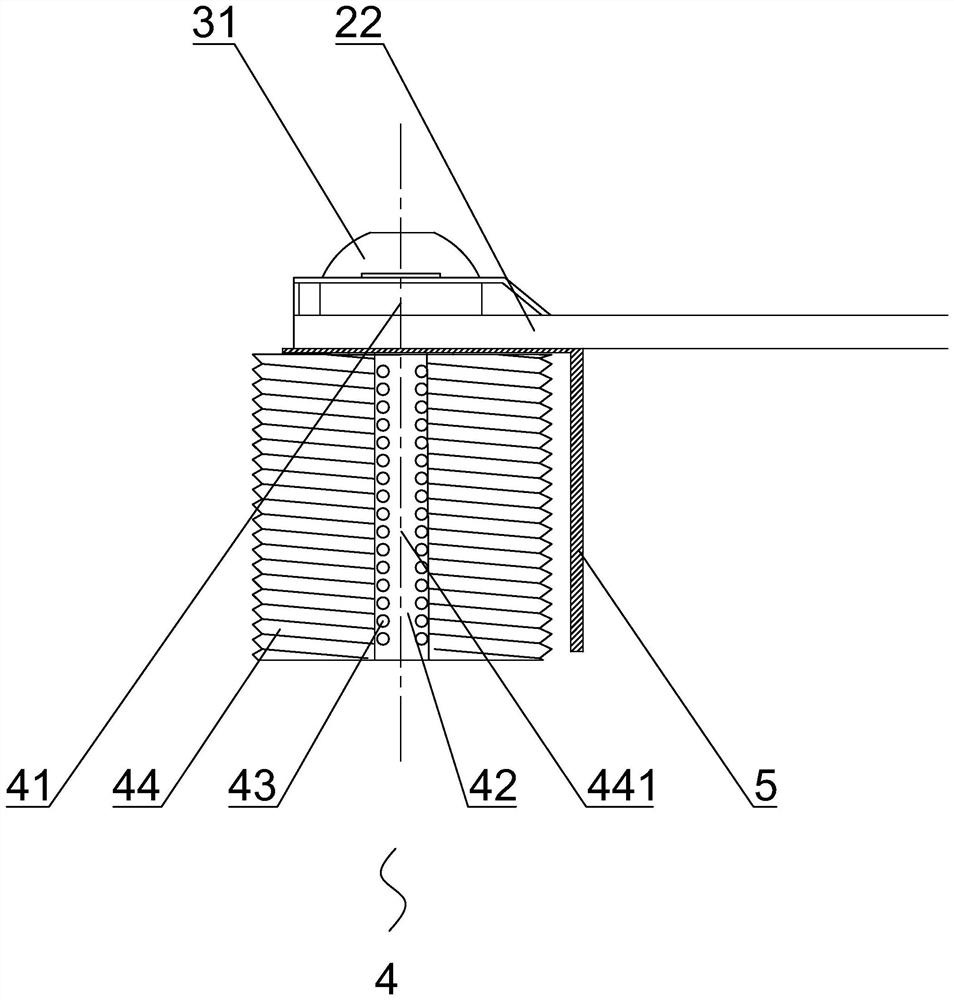

[0035] The dust suction system 3 includes a dust shield 31 , a hose 32 , and a vacuum cleaner 33 .

[0036] The drill bit 4 includes a motor 41 , a collection pipe 42 , a collection hole 43 , a grinding plate 44 , a through groove 441 , and a support rod 45 . The motor 41 is installed under the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com