Fabric, washing method thereof and old leisure garment

A fabric and water washing technology, which is applied in the textile field, can solve the problems of large water pollution, difficult to clean the production site, poor color fastness, etc., and achieve the effects of overcoming technical defects, environmental protection and pollution-free process, and small strong damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

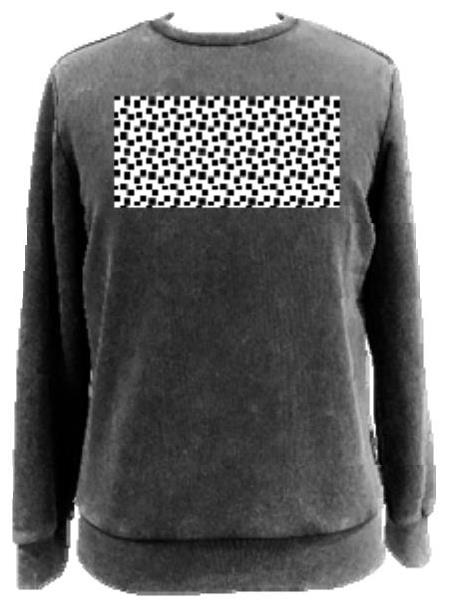

Image

Examples

Embodiment 1

[0074] Step 1: Weigh the washing water accessories:

[0075] Weigh 3kg of the washing water auxiliary material vinyl acetate-ethylene copolymer, and the weight ratio of the washing water auxiliary material to the fabric to be treated is 1:0.67.

[0076] Step 2: Prepare Color Additive Solution:

[0077] Weigh 270g of white thermosetting resin and 45g of catalyst, pour it into a chemical cup, add soft water to 0.9L, stir at room temperature for 5 minutes, filter through a filter screen, and set aside. The mass concentration of the white thermosetting resin was 300 g / L, and the mass concentration of the catalyst was 50 g / L. The ratio of the volume of the coloring solution to the weight of the washing water auxiliary material is 0.3L:1kg.

[0078] Step 3: Equipment Preprocessing

[0079] Put 5kg of clean waste cloth into the transformed washing machine, run it at room temperature for 20 minutes, make the machine fully dry and take it out.

[0080] Step 4: Form the Mixture:

...

Embodiment 2

[0096] The steps of Embodiment 2 are basically the same as those of Embodiment 1, except that:

[0097] Step 2: The mass concentration of the white thermosetting resin is 500 g / L.

Embodiment 3

[0099] The steps of Embodiment 3 are basically the same as those of Embodiment 1, except that:

[0100] Step 6: Let the modified washing machine after adding the fabric to be treated in Step 5 run at room temperature for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com