Filler dispersion liquid, ink and application thereof

A technology of dispersion liquid and ink, applied in the field of ink and its application, filler dispersion liquid, can solve the problems of open circuit, black hole, high cost in pattern production, reduce short circuit caused by hidden tin beads, good developability and low resin crack Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

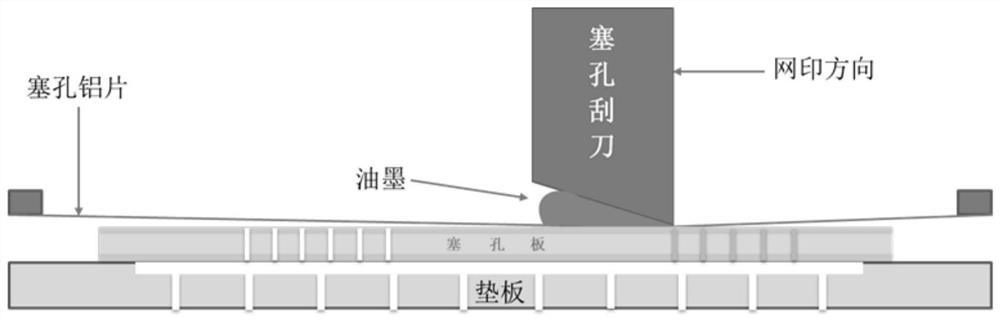

Method used

Image

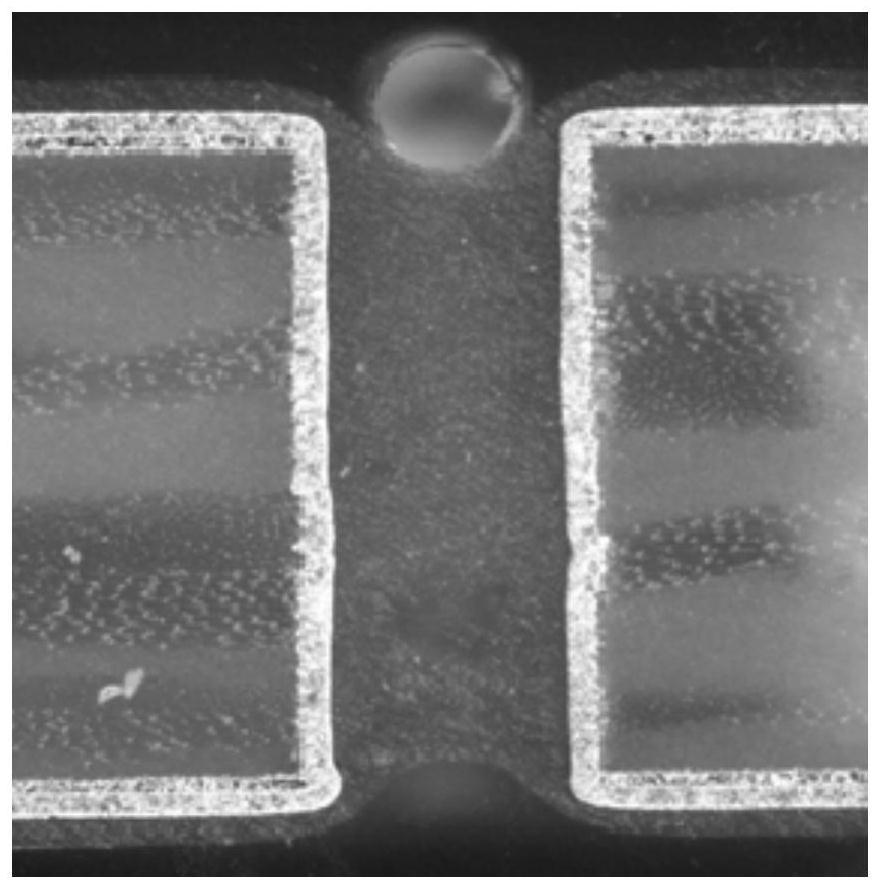

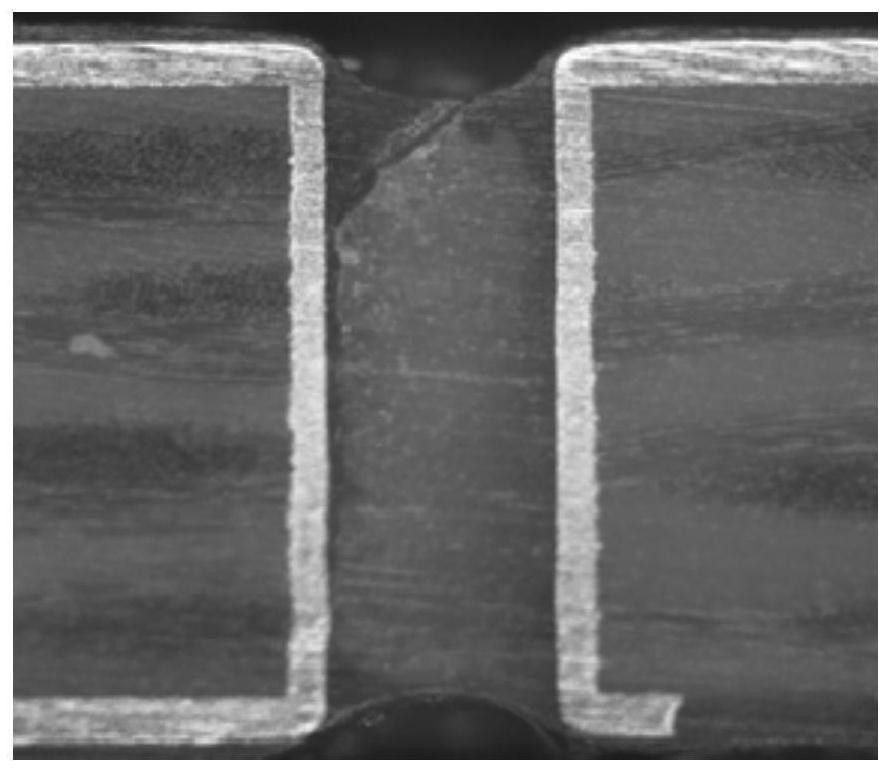

Examples

Embodiment 1

[0067] This embodiment provides the application of a filler dispersion liquid in the preparation of ink in a plugging process. The filler dispersion liquid is spherical silicon butanone, and the spherical silicon butanone is a dispersion liquid of silicon dioxide. The specific preparation process is as follows: silica (spherical, with an average particle size of 0.5 microns) and methyl ethyl ketone are mixed in a mass ratio of 90:10, and stirred for 10 hours.

[0068] The above-mentioned filler dispersion liquid is mixed with other auxiliary agents, main agents, hardeners and solvents to obtain plugging process ink.

[0069] Among them, the mass ratio of the filler dispersion in the ink is 5%, the mass ratio of the main agent in the ink is 19%, the mass ratio of the hardener in the ink is 31%, and other additives (including photoinitiators) (2,4,6-trimethylbenzoyl-diphenylphosphine oxide) 3.5%, thermal curing agent (triethylamine) 5%, filler 11.5% (TiO 2 and BaSO 4 , the ma...

Embodiment 2

[0075] This embodiment provides the application of a filler dispersion liquid in the preparation of ink for plugging process. The difference from Example 1 is: in the obtained ink, the mass percentages of the main agent and the hardener are 20% and 30% in sequence, and the corresponding mass percentage changes are filled by the solvent.

Embodiment 3

[0077] This embodiment provides the application of a filler dispersion liquid in the preparation of ink for plugging process. The difference from Example 1 is that in the obtained ink, the mass percentages of the main agent and the hardener are 17% and 28% in sequence, and the corresponding mass percentage changes are filled by the solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com