Foundation anti-scouring early-strength grouting material for underwater cast-in-place pile foundation and application of foundation anti-scouring early-strength grouting material

A grouting material and underwater pouring technology, used in sustainable waste treatment, solid waste management, climate sustainability, etc. The performance of the solidified soil fluctuates greatly, so as to avoid the inaccurate measurement, the strength does not shrink, and the strength increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

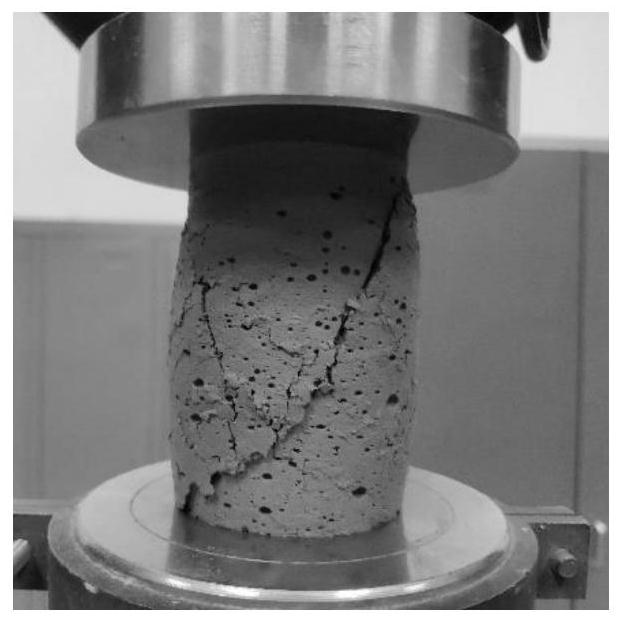

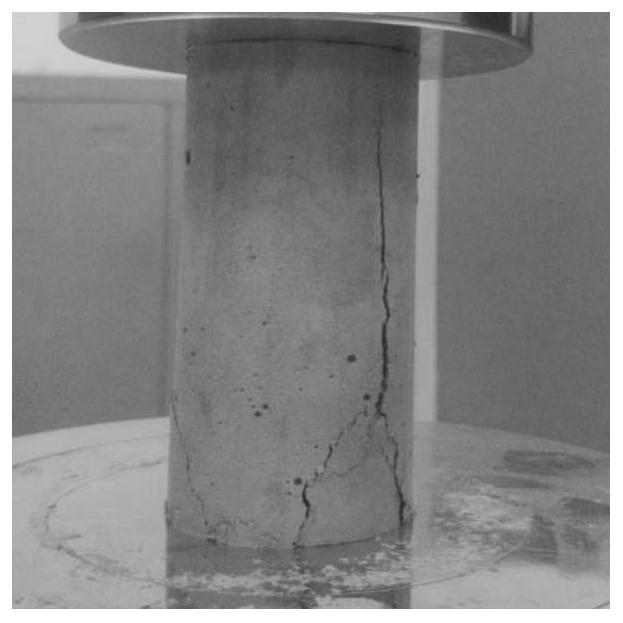

Image

Examples

Embodiment 1

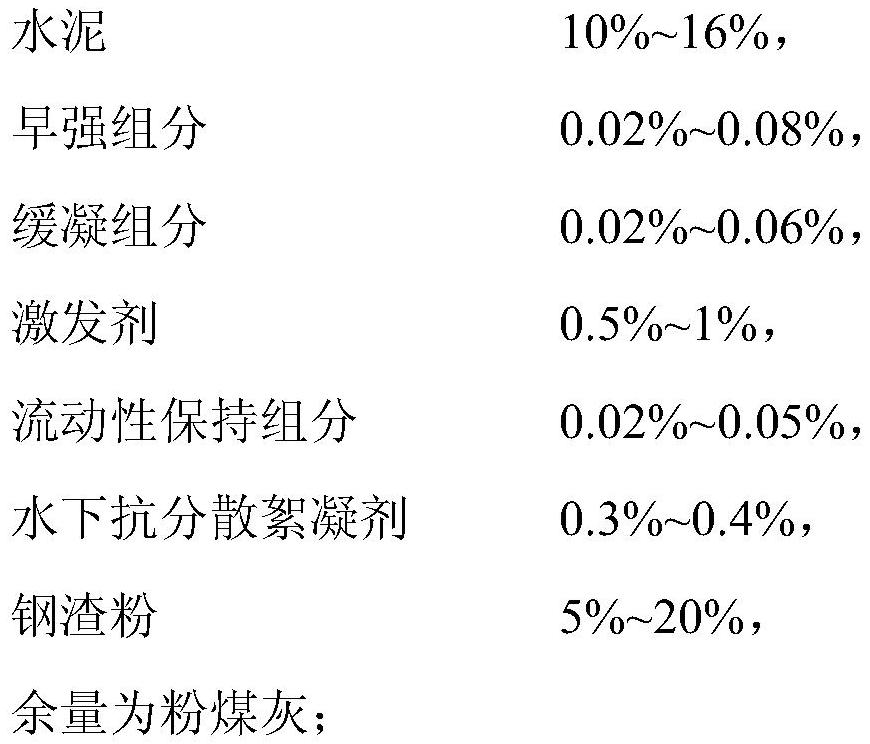

[0032] An anti-scour early-strength grouting material for an underwater cast-in-place pile foundation, the weight ratio of each component of the dry mix is as follows:

[0033]

[0034]

[0035] When the grouting material is used, the water is 65% of the mass ratio of the dry mixture of the grouting material, and the grouting material 1 is obtained.

[0036] Among them, the early-strength component is lithium hydroxide, the retarding component is borax, the activator is sodium sulfate, and the fluidity-maintaining component is a carboxyl-protected polycarboxylate water-reducing agent (water reducing rate ≥ 25%). The anti-dispersing flocculant is hydroxypropyl methylcellulose.

Embodiment 2

[0038] An anti-scour early-strength grouting material for an underwater cast-in-place pile foundation, the weight ratio of each component of the dry mix is as follows:

[0039]

[0040] When the grouting material is used, the water is 70% of the mass ratio of the dry mixture of the grouting material, and the grouting material 2 is obtained.

[0041] Among them, the early strength component is lithium carbonate, the retarding component is citric acid, the activator is sodium carbonate, and the fluidity maintaining component is cross-linked polycarboxylate water reducing agent (water reducing rate ≥ 25%). The anti-dispersing flocculant is hydroxyethyl methyl cellulose.

Embodiment 3

[0043] An anti-scour early-strength grouting material for an underwater cast-in-place pile foundation, the weight ratio of each component of the dry mix is as follows:

[0044]

[0045]

[0046] When the grouting material is used, the water is 75% of the mass ratio of the dry mixture of the grouting material, and the grouting material 3 is obtained.

[0047] Among them, the early strength component is lithium sulfate, the retarding component is tartaric acid, the activator is sodium silicate, and the fluidity maintaining component is a cross-linked polycarboxylate water reducer (water reducing rate ≥ 25%). The anti-dispersing flocculant is hydroxyethyl methyl cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com