Curing process for municipal dewatered sludge

A technology of dewatering sludge and solidification process, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc. It can solve the problems of increasing landfill volume, adding more curing agent, and occupying a large area. problem, to achieve the effect of less curing agent dosage, good curing effect and small volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

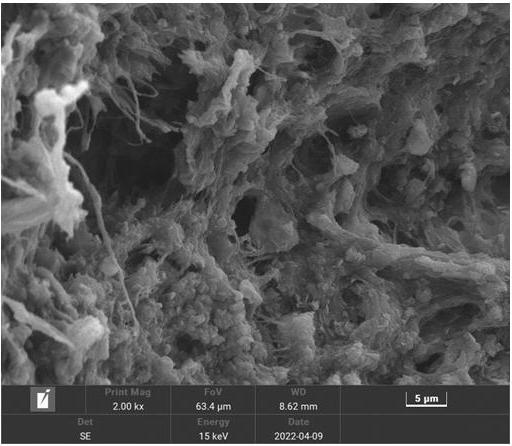

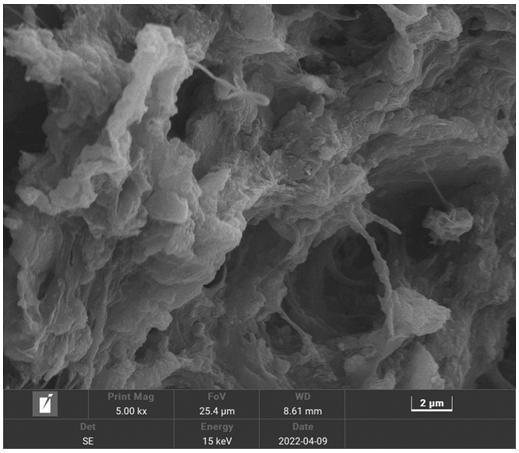

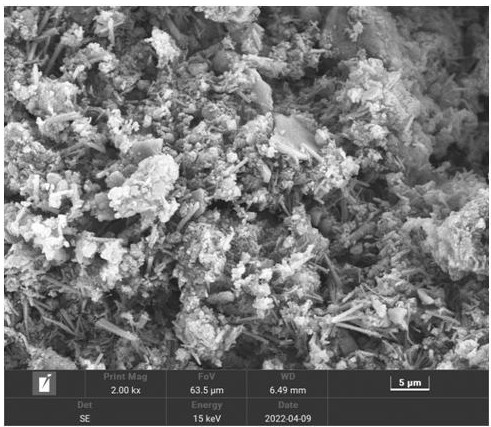

Image

Examples

Embodiment 1

[0030] (1) First put 1.6kg of wet sludge (80% moisture content) into the stirring pot and stir it evenly;

[0031] (2) Prepare a certain quality of cellulase, lipase, and protease, mix them with equal quality, and weigh 3% of the composite enzyme according to the weight of the wet sludge;

[0032] (3) Prepare the complexing agent citric acid granules, and weigh 0.5% of citric acid according to the weight of the wet sludge;

[0033] (4) Mix the compound enzyme in (2) and the citric acid in (3) evenly;

[0034] (5) Put the mixture of (4) into the sludge of (1) through the funnel, stir once automatically, then slowly stir for 5 minutes, and stir quickly for 5 minutes;

[0035] (6) Put the agitated sludge in (5) into a conical flask, at 40°C, 200r·min -1 Oscillation treatment for 120h;

[0036] (7) After the enzymatic hydrolysis is completed, take out the sludge in (6), weigh out the sludge mass, and put it into the stirring pot to stir evenly;

[0037] (8) Weigh 3% potassium ...

Embodiment 2

[0047] (1) First put 1.6kg of wet sludge (80% moisture content) into the stirring pot and stir it evenly;

[0048] (2) Prepare a certain quality of cellulase, lipase, and protease, mix them with equal quality, and weigh 3% of the composite enzyme according to the weight of the wet sludge;

[0049] (3) Prepare the complexing agent citric acid granules, and weigh 0.5% citric acid according to the weight of the wet sludge;

[0050] (4) Mix the compound enzyme in (2) and the citric acid in (3) evenly;

[0051] (5) Put the mixture of (4) into the sludge of (1) through the funnel, stir once automatically, stir slowly for 5 minutes, and stir quickly for 5 minutes;

[0052] (6) Put the agitated sludge in (5) into a conical flask, at 40°C, 200r·min -1 Oscillation treatment for 120h;

[0053](7) After the enzymatic hydrolysis is completed, take out the sludge in (6), weigh out the sludge mass, and put it into the stirring pot to stir evenly;

[0054] (8) Weigh 4% potassium ferrate p...

Embodiment 3

[0063] (1) First put 1.6kg of wet sludge (80% moisture content) into the stirring pot and stir it evenly;

[0064] (2) Prepare a certain quality of cellulase, lipase, and protease, mix them with equal quality, and weigh 3% of the composite enzyme according to the weight of the wet sludge;

[0065] (3) Prepare the complexing agent citric acid granules, and weigh 1% of citric acid according to the weight of the wet sludge;

[0066] (4) Mix the compound enzyme in (2) and the citric acid in (3) evenly;

[0067] (5) Put the mixture of (4) into the sludge of (1) through the funnel, stir once automatically, then slowly stir for 5 minutes, and stir quickly for 5 minutes;

[0068] (6) Put the agitated sludge in (5) into a conical flask, at 40°C, 200r·min -1 Oscillation treatment for 120h;

[0069] (7) After the enzymatic hydrolysis is completed, take out the sludge in (6), weigh out the sludge mass, and put it into the stirring pot to stir evenly;

[0070] (8) Weigh 3% potassium fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com