Well mouth centering device of workover rig and well mouth centering method of elevator of workover rig

A technology of centering device and workover rig, which is used in earth-moving drilling, drilling equipment, transportation and packaging, etc. It can solve the problems of not achieving fast and accurate centering, affecting the construction progress, and not having level adjustment, etc., so as to improve the operation. The effect of construction efficiency, avoiding wear and wellhead hanging, and eliminating hidden dangers of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the following description of the present invention, the orientation or positional relationship indicated by the terms "upper", "lower", "front", "rear", "left", "right", "inner", "outer", etc. is based on the attached The orientation or positional relationship shown in the figures is only for the convenience of describing the present invention and simplifying the description, and does not mean that the device must have a specific orientation.

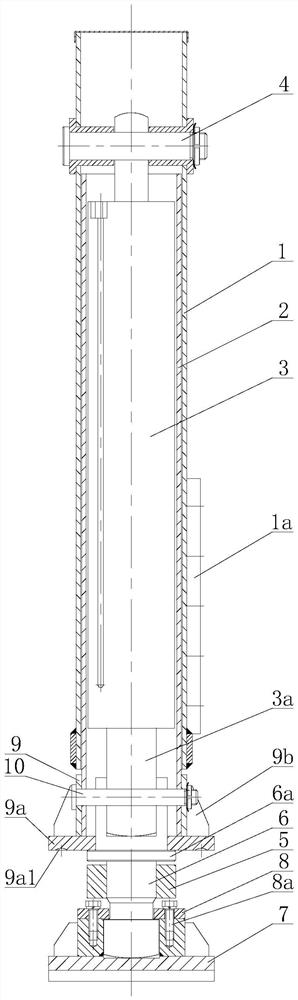

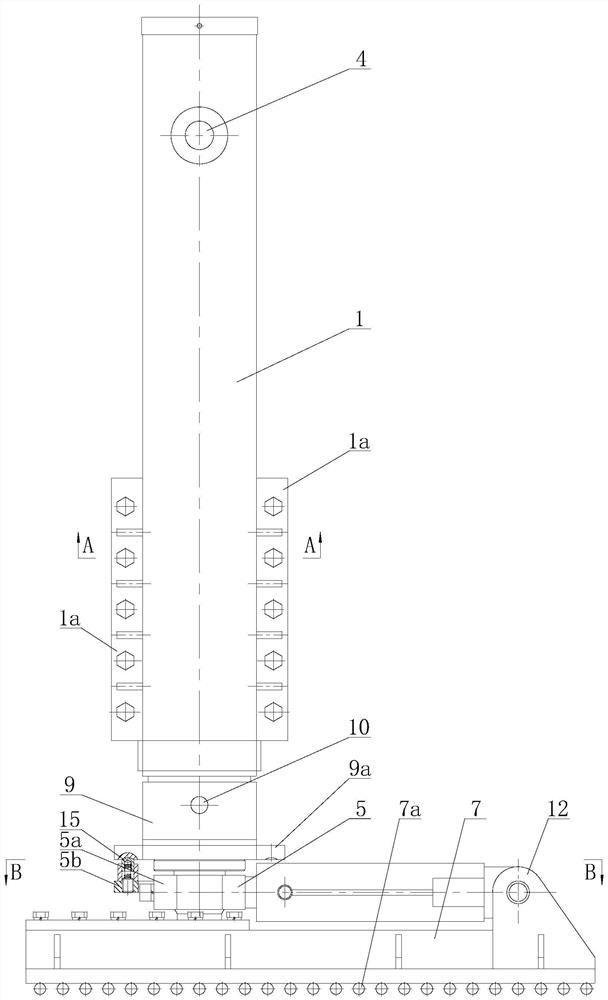

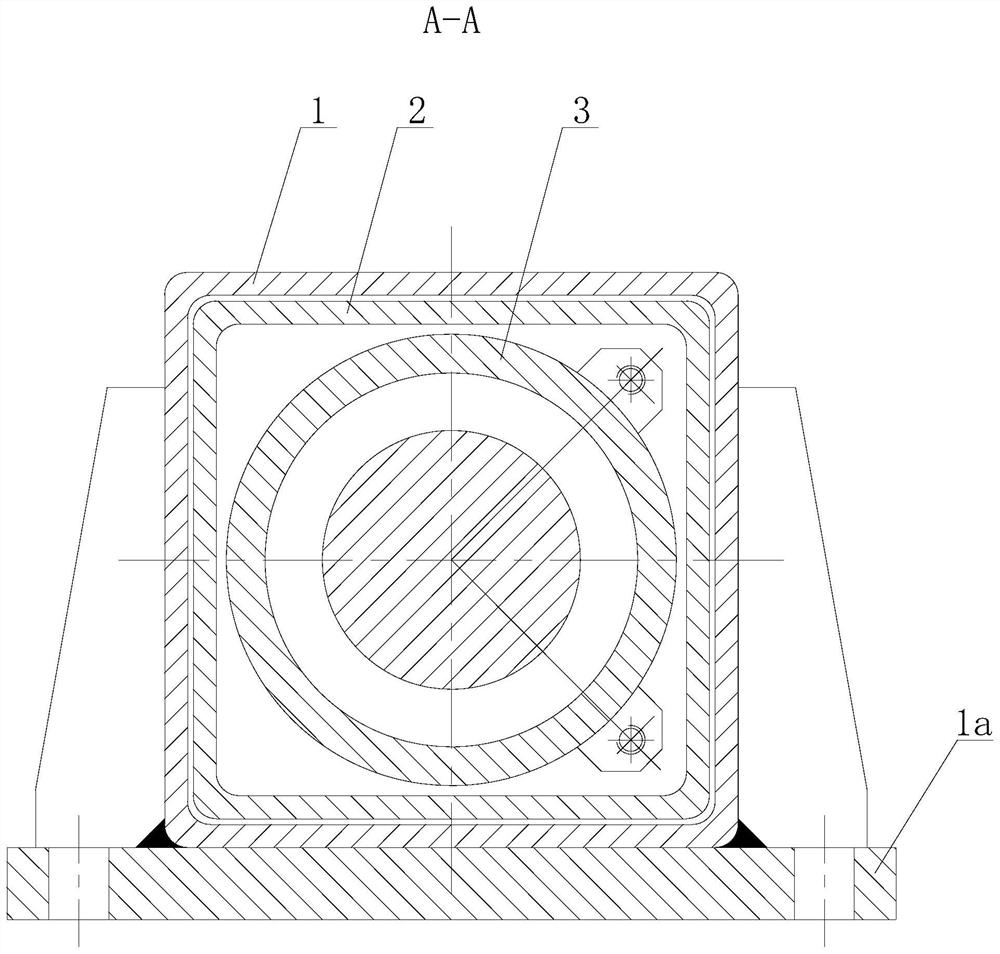

[0039] like Figure 1 to Figure 5 As shown in the figure, the wellhead centering device of the workover rig of the present invention comprises an outer leg housing 1 connected below the four support points of the workover rig, and the outer wall of each leg outer casing 1 is welded with flanges of the outer wall of the outrigger respectively. 1a, the outer shell flange 1a of the outrigger is fixedly connected with the chassis of the workover rig through bolts. The inner cavity of the outrigger outer casing 1 is respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com