Rotary drum filter for treating by-products in production of titanium dioxide and use method of rotary drum filter

A by-product, titanium dioxide technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of high cost of filter plates and filter cloths, unfavorable cost control personnel, etc., to achieve production cost reduction, Ease of air drying and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

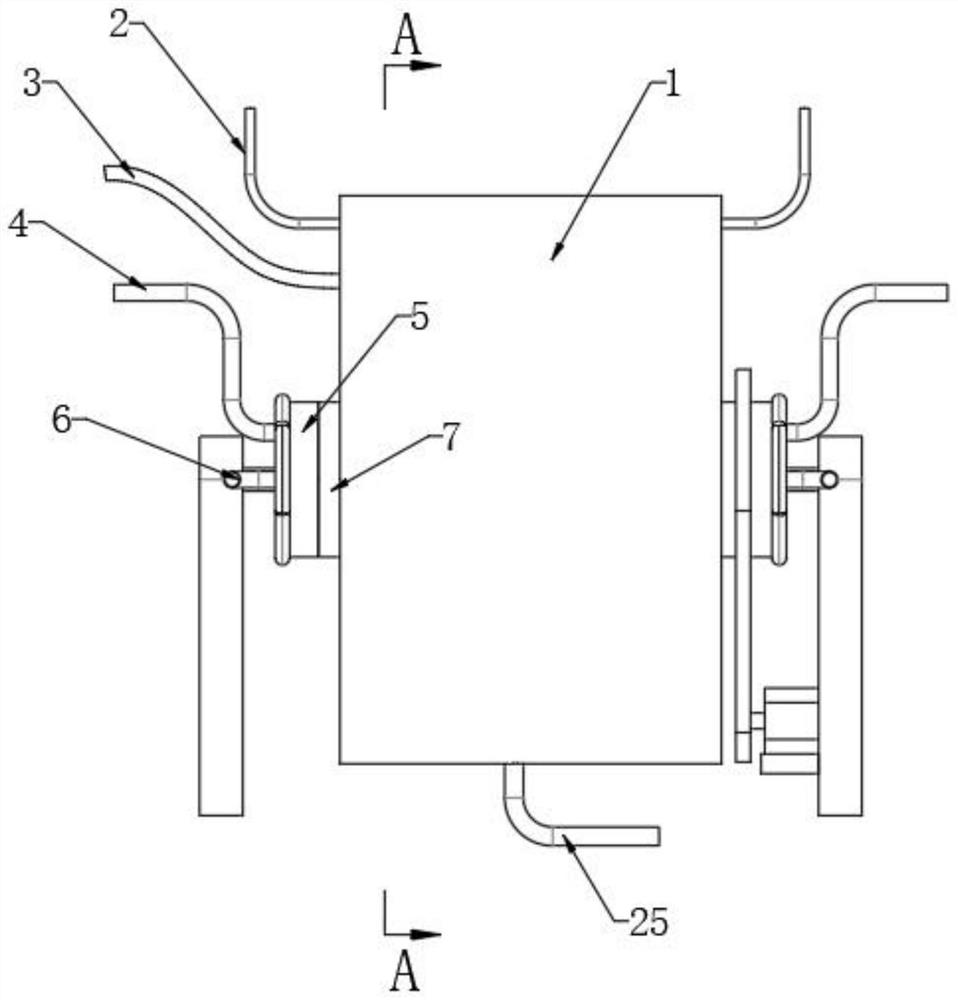

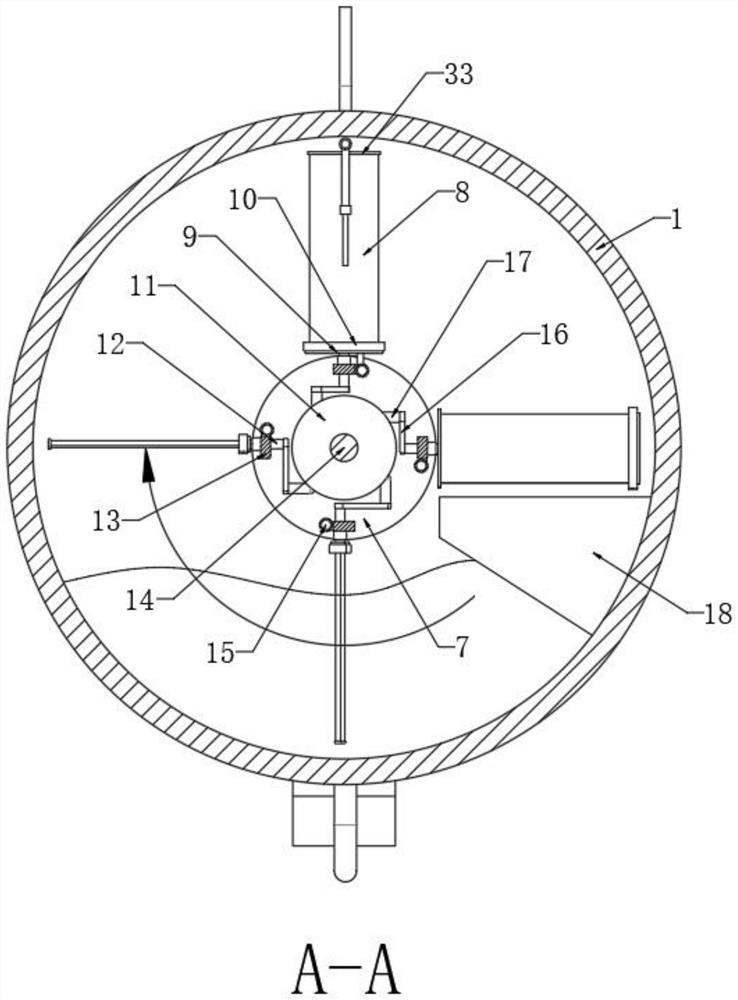

[0036] see Figure 1 to Figure 10 , the present invention provides a technical solution: a rotary drum filter for processing by-products of titanium dioxide production, comprising a pressurized chamber 1, the outer walls of both sides of the pressurized chamber 1 are provided with holes, and the two holes are A rotatable rotating disk 7 is installed, and the opposite surfaces of the two rotating disks 7 are jointly fixed with a plurality of connecting plates 13 distributed in a ring shape. The outer wall of each connecting plate 13 is equipped with a filter assembly, and the outer wall of each connecting plate 13 Both are fixed with a drain pipe 15 that communicates with the filter assembly, and the outer walls on the opposite sides of the two rotating disks 7 are equipped with a drain assembly and a backwash assembly.

[0037]The outer wall of the pressurized cabin 1 is connected with an air intake pipe 3 for inflating the pressurized cabin 1, the bottom of the pressurized ca...

Embodiment 2

[0061] Different from the first embodiment, the movement of the adjusting plate 33 can also be controlled by driving the telescopic rod, so that the adjustment between the adjusting plate 33 and the mounting plate 9 is more stable.

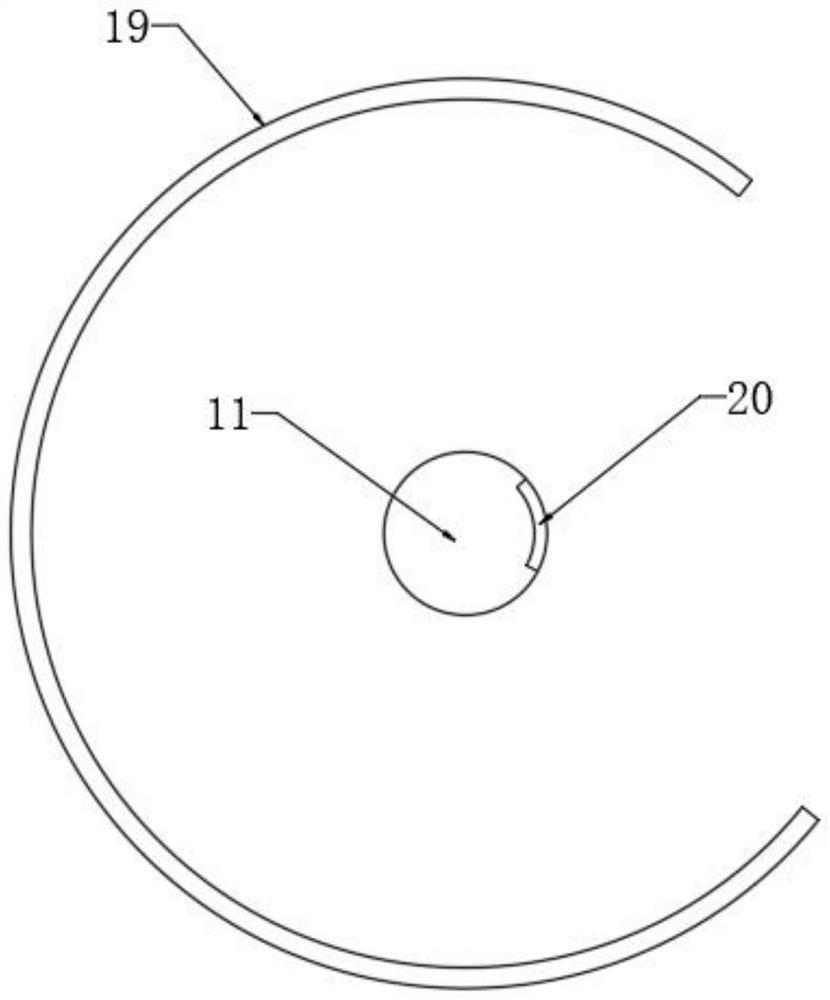

[0062]To sum up, through the continuous rotation of the rotating disk 7, the filter element 8 will be immersed in the slurry, and the titanium gypsum will be filtered at the same time. Prevent the solid phase sedimentation of the titanium gypsum in the slurry, and then when the filter element 8 rotates to the top of the collecting tank 18, the titanium gypsum attached to it will be blown off by the reverse blowing pipe 6, and fall into the collecting tank for collection. At the same time, the movement of the scraping sleeve 10 can further scrape off the titanium gypsum remaining on its surface, so that the filter element 8 can enter the slurry again to maintain its filtering effect.

[0063] A method for using a rotary drum filter for processing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com