Feed additive for lactating sows and preparation method thereof

A technology for feed additives and lactating sows, applied in the field of feed additives, can solve the problems of unable to maintain the lactation level of lactating sows, unsatisfactory conditioning ability of lactating sows, poor applicability of lactating sows, etc., to improve lactation ability, Promote the development of mammary glands and avoid the effect of low milk secretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

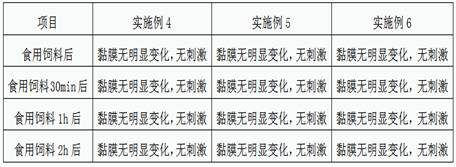

Examples

Embodiment 1

[0045] A feed additive for lactating sows, in parts by weight, is composed of the following raw materials: 30 parts of compound amino acids, 3 parts of compound enzymes, 20 parts of synergists, 1 part of microcrystalline cellulose, 3 parts of dandelion extract, 10 parts of formic acid, 1 part of soybean isoflavones, 5 parts of rice bran powder, and 10 parts of black bean hull powder.

[0046] The compound amino acid is composed of the following components: DL-methionine, L-proline, lysine, arginine, tryptophan, and cysteine. Wherein, the weight ratio of DL-methionine, L-proline, lysine, arginine, tryptophan, and cysteine is 20:10:15:5:10:5.

[0047]The complex enzyme is composed of the following components: cellulase, protease, serrapeptase, and glucanase. Wherein, the weight ratio of cellulase, protease, serrapeptase and glucanase is 1:8:2:2.

[0048] The enzymatic activity of the cellulase is 200,000 u / g, the enzymatic activity of the protease is 100,000 u / g, the enzymat...

Embodiment 2

[0075] A feed additive for lactating sows, by weight, consists of the following raw materials: 35 parts of compound amino acids, 5 parts of compound enzymes, 25 parts of synergists, 2 parts of microcrystalline cellulose, 4 parts of dandelion extract, 12 parts of formic acid, 2 parts of soybean isoflavones, 8 parts of rice bran powder, 12 parts of black bean hull powder.

[0076] The compound amino acid is composed of the following components: DL-methionine, L-proline, lysine, arginine, tryptophan, and cysteine. Wherein, the weight ratio of DL-methionine, L-proline, lysine, arginine, tryptophan, and cysteine is 25:12:20:8:12:6.

[0077] The complex enzyme is composed of the following components: cellulase, protease, serrapeptase, and glucanase. Wherein, the weight ratio of cellulase, protease, serrapeptase and glucanase is 1.5:9:2.5:2.5.

[0078] The enzymatic activity of the cellulase is 200,000 u / g, the enzymatic activity of the protease is 100,000 u / g, the enzymatic acti...

Embodiment 3

[0105] A feed additive for lactating sows, by weight, consists of the following raw materials: 40 parts of compound amino acids, 7 parts of compound enzymes, 30 parts of synergists, 3 parts of microcrystalline cellulose, 5 parts of dandelion extract, 15 parts of formic acid, 3 parts of soybean isoflavones, 10 parts of rice bran powder, and 15 parts of black bean skin powder.

[0106] The compound amino acid is composed of the following components: DL-methionine, L-proline, lysine, arginine, tryptophan, and cysteine. Wherein, the weight ratio of DL-methionine, L-proline, lysine, arginine, tryptophan, and cysteine is 30:15:30:10:15:10.

[0107] The complex enzyme is composed of the following components: cellulase, protease, serrapeptase, and glucanase. Wherein, the weight ratio of cellulase, protease, serrapeptase and glucanase is 2:10:3:3.

[0108] The enzymatic activity of the cellulase is 200,000 u / g, the enzymatic activity of the protease is 100,000 u / g, the enzymatic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com