Automatic visual sorting equipment applied to crayfish

An automatic weighing device, lobster technology, applied in sorting, application, climate change adaptation, etc., can solve the problems of low automation equipment, waste of labor, cumbersome assembly line technology, etc., to achieve high precision, wide application range, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical content of the present invention, specific embodiments are given and described below in conjunction with the accompanying drawings.

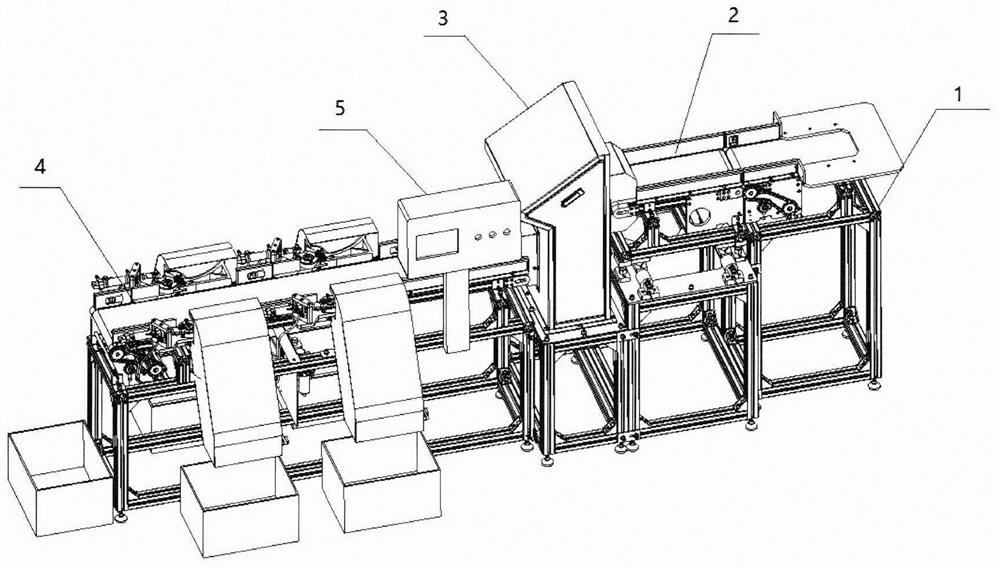

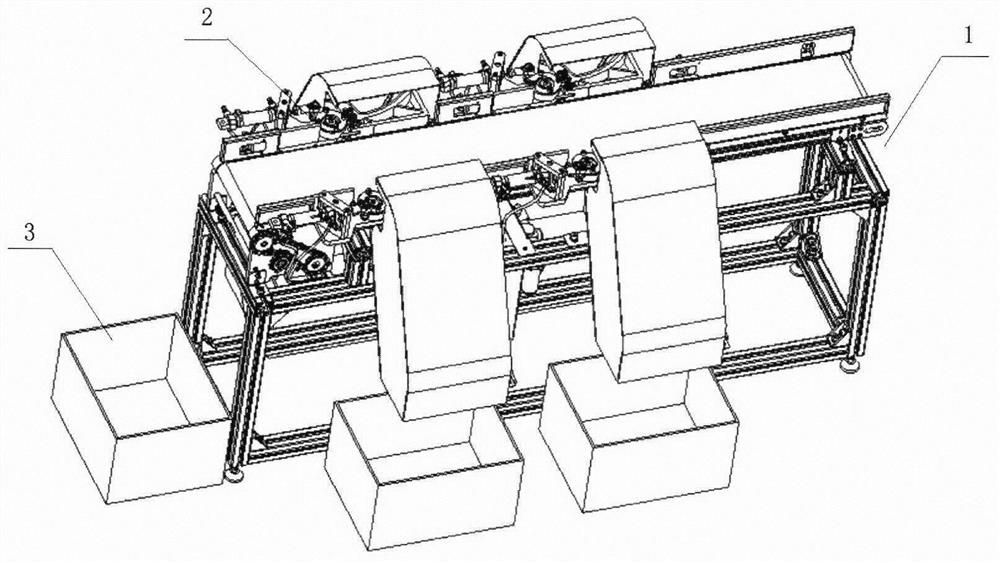

[0024] like figure 1 shown,

[0025] In this embodiment, figure 1 The middle 1 is the feeding device, which is mainly composed of a feeding chassis device, a feeding transmission device and a feeding table. The entire feeding chassis device is constructed of aluminum alloy, which ensures the stability of the feeding transmission device; The device uses a stepper motor to drive the sprocket as the transmission power, and the transmission belt uses a food-grade nylon conveyor belt for product transmission. The speed of the entire belt is adjustable within 2-20m / min; the feeding table is mainly used for placing products, which is convenient for feeding. . 2 is an automatic weighing device, which is mainly composed of a weighing bottom frame device, a general weighing device and a supporting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com