Anchoring support utilizing shallow foundation pit in pit with large height difference and foundation pit construction method

An anchor-pulling support and shallow foundation pit technology, which is applied in basic structure engineering, filling, excavation, etc., can solve the problems of low bending stiffness, inability to meet the safety and stability of pits in large height difference pits, etc. Controlled lateral deformation, good applicability, reduced disturbance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

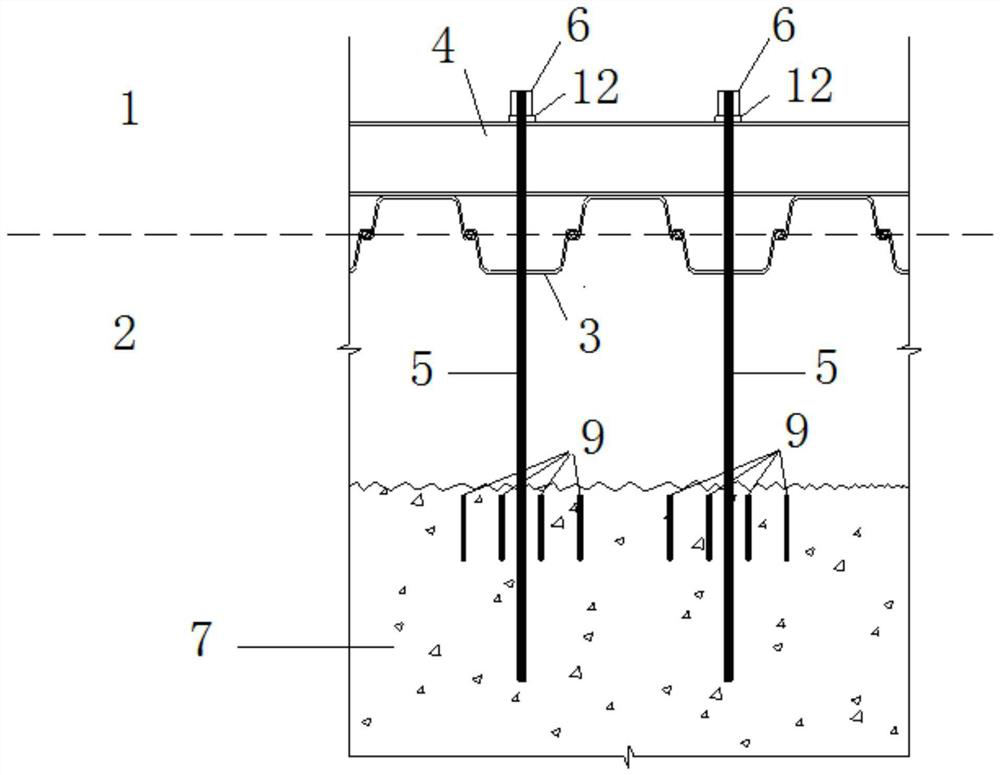

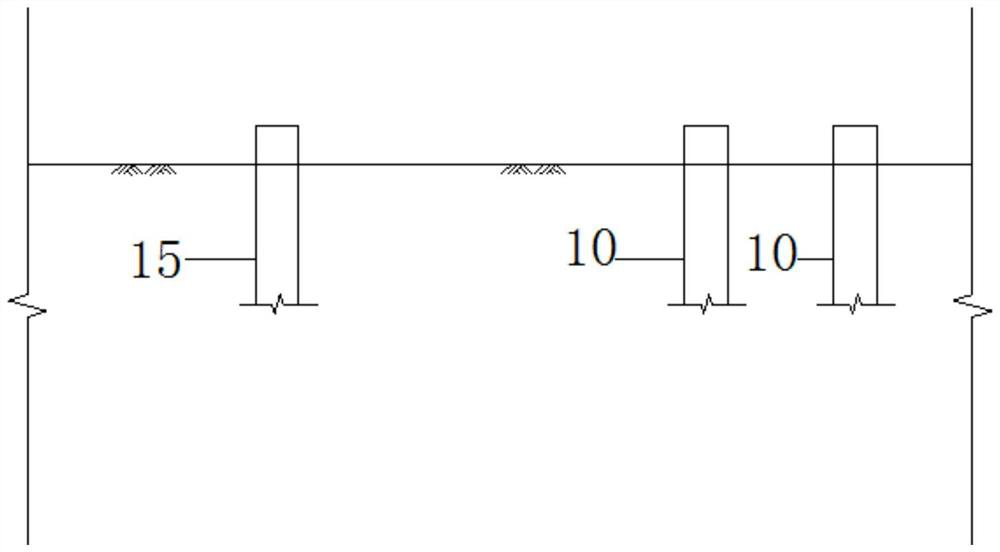

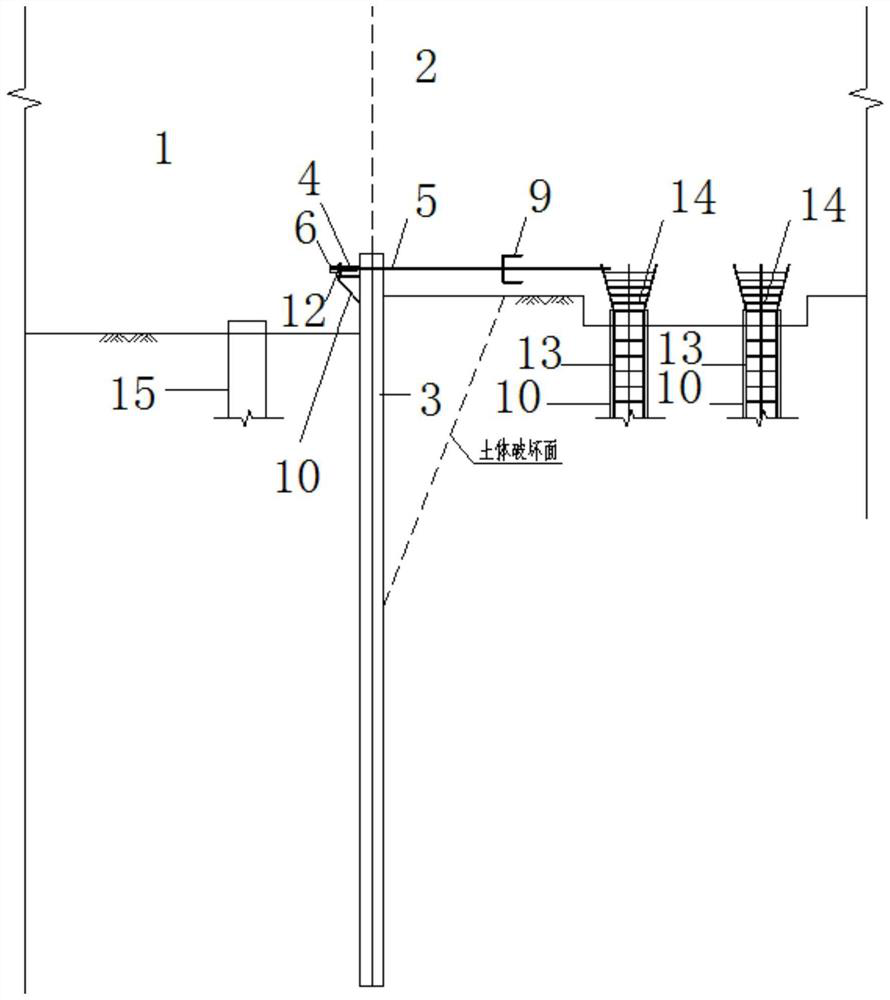

[0057] like figure 1 and Figure 4 As shown in the figure, in the pit with a large height difference, the pit is supported by the anchor pull of the shallow foundation pit, and is set between two foundation pits; wherein, one foundation pit is set at the bottom of the other foundation pit, and the bottom depth is greater than that of the other foundation pit. The deep foundation pit 1 above 3.5 meters from the bottom of the pit; the other foundation pit is the shallow foundation pit 2.

[0058]The support structure is completed before the excavation of the deep foundation pit 1, including support components, force transmission components and anchor-pulling support components;

[0059] The support assembly includes a plurality of steel sheet piles 3 arranged around the side wall of the deep foundation pit 1;

[0060] The upper ends of all the steel sheet piles 3 are higher than the bottom of the shallow foundation pit 2, and the parts facing the inner side of the deep foundat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com