Dyeing device and dyeing process for leather fabric

A dyeing device and leather technology, which is applied in the field of leather fabric dyeing devices, can solve the problems of uneven dyeing of leather fabrics, and achieve the effects of improving dyeing effects, promoting permeability, and enhancing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

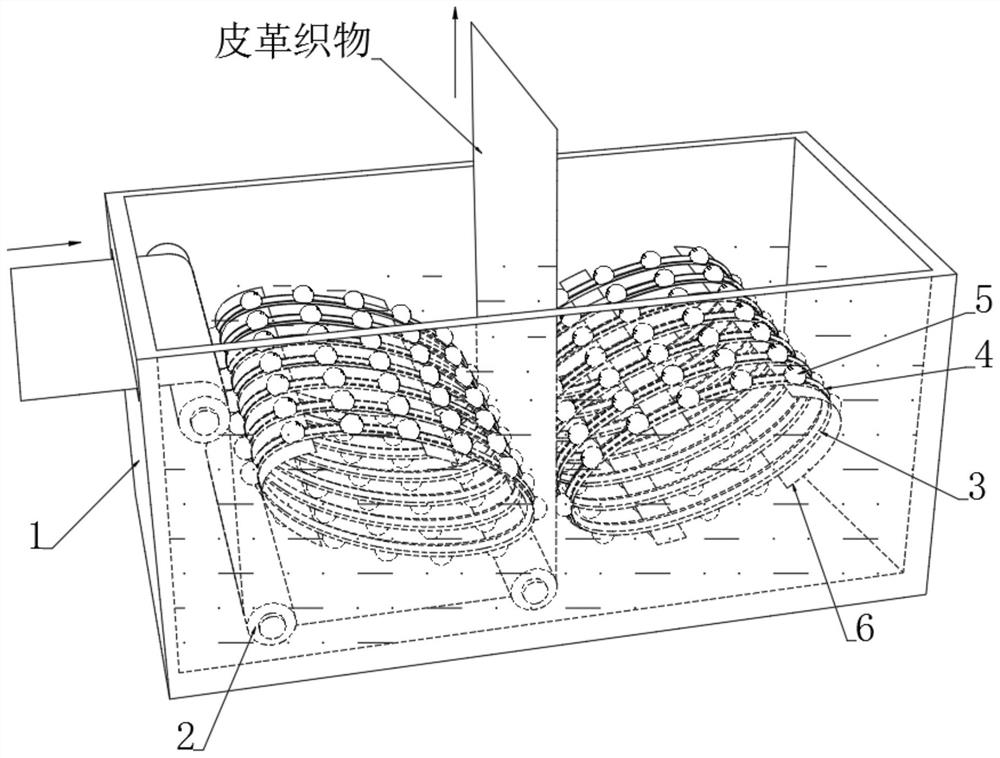

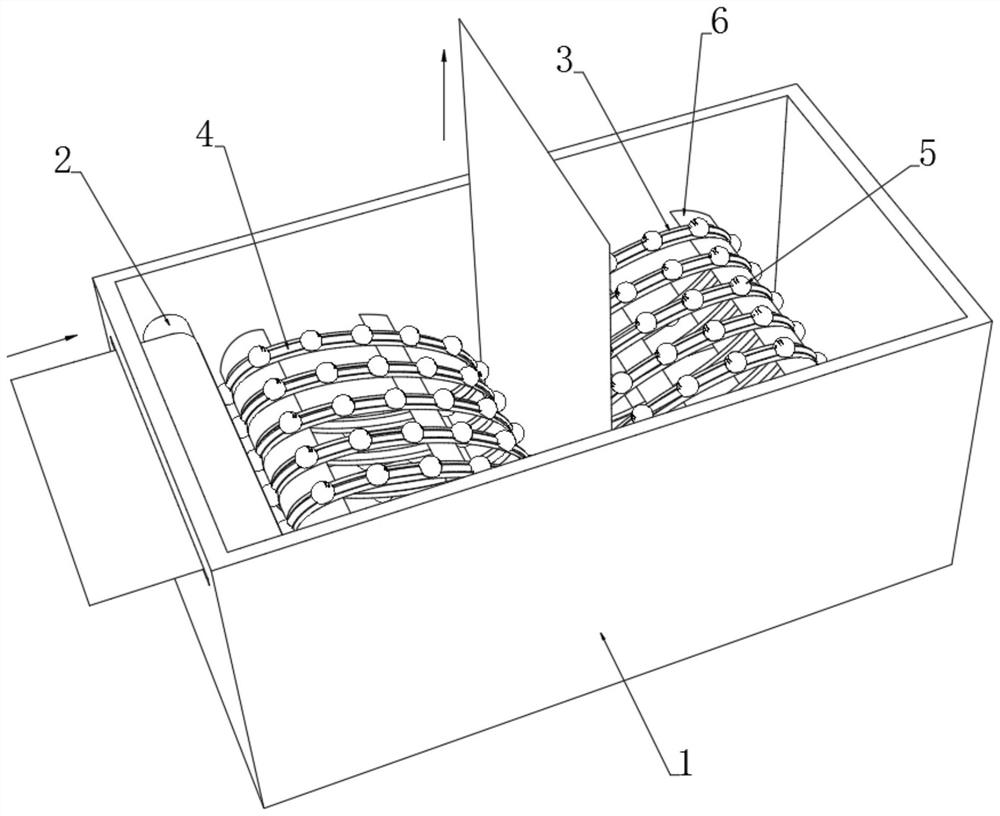

[0048] see Figure 1-2 , a leather fabric dyeing device, comprising a dye box 1, one end of the inner side of the dye box 1 is provided with a plurality of guide rollers 2 for wrapping the leather fabric, the leather fabric bypasses the guide roller 2 and extends outward from the middle of the dye box 1, and the guide roller 2 extends outward from the middle of the dye box 1. There are three rollers 2, and a plurality of connecting rings 3 are distributed at right angles. The top side of the dye box 1 is provided with a feed port corresponding to the position of the upper guide roller 2, and the leather fabric penetrates into the dye box 1 from the feed port. , and mechanically pull outwards from the middle of the dyeing box 1 through the three guide rollers 2 of the connecting ring in turn, and the mechanical pulling method is the prior art.

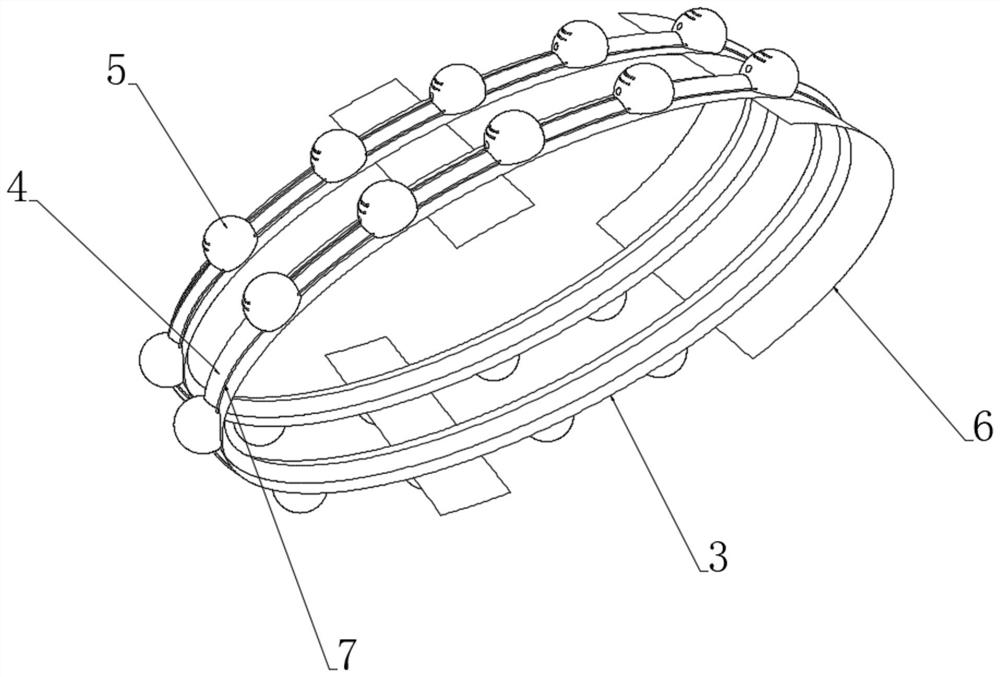

[0049] see Figure 1-3 , both sides inside the dye box 1 are provided with a set of suction and spray components, and a set of suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com