Method for improving internal quality of ship plate steel

An internal quality, ship plate steel technology, applied in the direction of manufacturing converters, etc., can solve the problems of the gap in the qualification rate of steel plate inspection, high air humidity, and hydrogen addition in molten steel, so as to improve the inspection qualification rate, improve user satisfaction, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Taking furnace number 18ND3166 and steel grade AH36 as an example, the specific embodiments of the present invention are further described, but are not intended to limit the scope of the present invention:

[0038] An AH36 high-strength ship plate steel with a thickness of 36mm contains the following chemical components by mass percentage: C: 0.14%, Si: 0.14%, Mn: 1.47%, P: 0.018%, S: ≤ 0.006%, Ni: 0.008% , V: 0.0031%, Nb: 0.0042%, Ti: 0.016%, Als: 0.018%, and the balance is Fe.

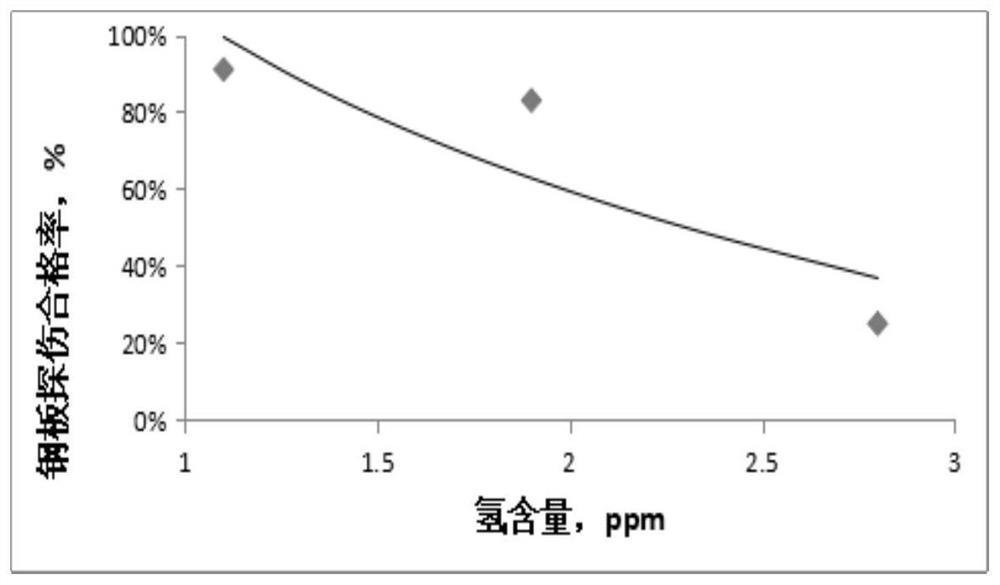

[0039] The turnover time of the turnover tank is 92min, the tapping temperature of the converter is 1697℃, the high carbon ferromanganese is 1.99t, no recarburizer is added, the smelting cycle of the LF furnace is 26min, the heating time is 5.02min, the hydrogen content of the molten steel is 1.7ppm, the steel plate is not stacked, and the steel plate is not stacked. The qualified rate of flaw detection is 88.46%.

Embodiment 2

[0041]Taking furnace number 18ND4318 and steel grade AH36 as examples, the specific embodiments of the present invention are further described, but are not intended to limit the scope of the present invention:

[0042] An AH36 high-strength ship plate steel with a thickness of 24-25mm contains the following chemical components by mass percentage: C: 0.135%, Si: 0.135%, Mn: 1.46%, P: 0.013%, S: 0.005%, Ni: 0.0068 %, V: 0.03%, Nb: 0.018%, Ti: 0.015%, Als: 0.020%, and the balance is Fe.

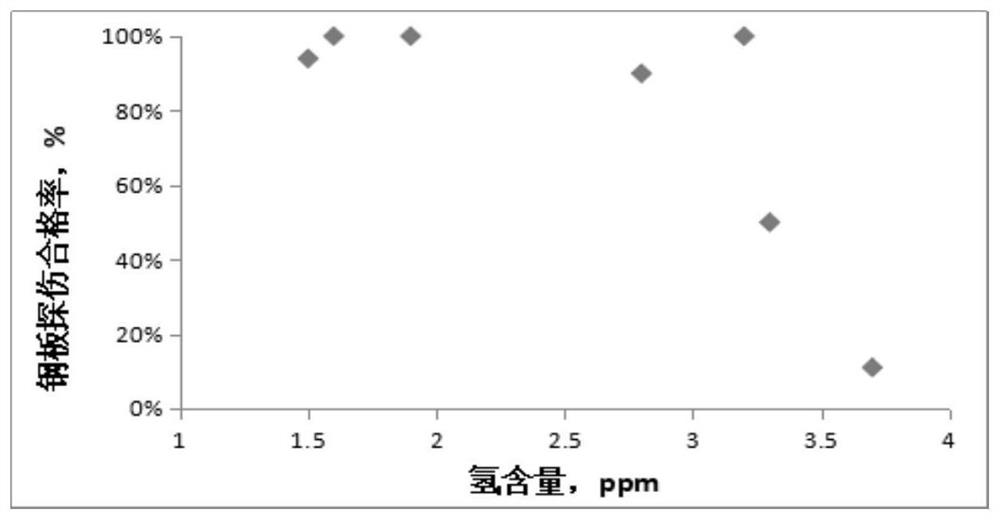

[0043] The turnover time of the turnover tank is 88min, the tapping temperature of the converter is 1696℃, the high carbon ferromanganese is 1.79t, no recarburizer is added, the smelting cycle of the LF furnace is 25min, the heating time is 2.12min, the hydrogen content of the molten steel is 3.2ppm, and the stacking temperature of the steel plate is 264℃. The stacking time is 24.8h, and the qualified rate of steel plate flaw detection is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com