Method for constructing coexistence of aerobic fungi and facultative or anaerobic microorganisms by utilizing 3D printing

An anaerobic microorganism, 3D printing technology, applied in the field of biological materials and synthetic biology, can solve the problems of artificial microorganism co-cultivation system difficulty, difficulty in maintaining different strain groups, etc., to achieve high specific surface area and improve the effect of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 3D printing fence structure living material

[0040] The living material of the fence structure was printed using an extrusion-based 3D printer (EFL-BP66). First, a computer-aided system was used to design a 3D fence structure with high mass transfer, and then a 3D printing gel was prepared. The 3D printing gel is prepared as follows:

[0041] 1 vol.% overnight culture S. cerevisiae and 1 wt.% phenyl-2,4,6-trimethylbenzoyl phosphate (LAP) photoinitiator was added to 5 wt.% PVA-GMA. The dissolved solution was mixed with 2 wt.% PBA-SA at a ratio of 1:2 and then vortexed. After this, incubate on ice for 10 min to keep the gel free of air bubbles. The gel was then transferred into a syringe barrel with a volume of 5 mL and a nozzle length of 20 mm and deposited into continuous filaments at a printing speed of 50-70 mm / s. Light curing (405 nm) for 30 seconds after printing each layer. Finally, the living material of the printed fence structure was immediatel...

Embodiment 2

[0042] Example 2 Microbial visualization of biomass accumulation inside living materials

[0043] Using the above-mentioned method of 3D spatiotemporal design of living materials to print green fluorescent protein S. cerevisiae . Immediately after printing, rinse 6 times with PBS. Images of the living material were taken under a fluorescence microscope, and then the fence-structured living material was transferred to the culture medium (potassium dihydrogen phosphate: 3 g / L, ammonium sulfate: 5 g / L, magnesium sulfate heptahydrate: 0.5 g / L , uracil: 0.15 g / L, glucose: 40 g / L) for culture. Fluorescence images of living material were taken every 12 hours. Fluorescence microscopy uses the same parameters to ensure consistent fluorescence readings. Fluorescence was quantified using ImageJ, and the mean fluorescence intensity of 6 images collected at all time points for each printed sample was used as a parameter for biomass accumulation over time ( figure 2 (A)). like fig...

Embodiment 3

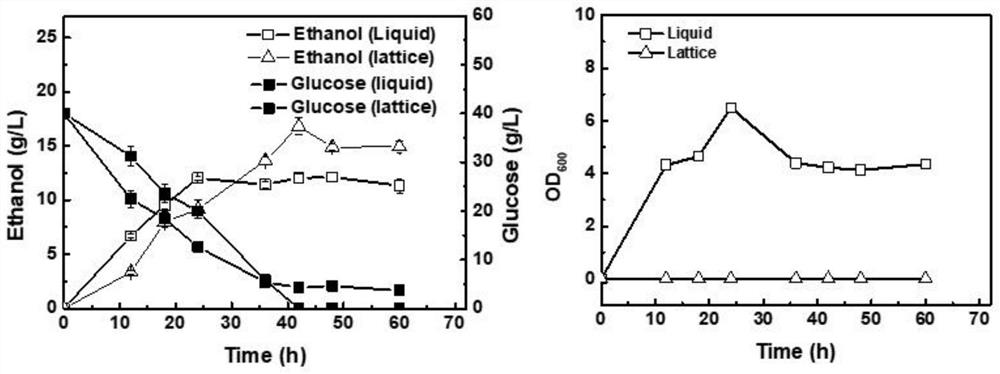

[0044] Example 3 3D printing living material for ethanol fermentation

[0045] In order to verify the ability of 3D printed living materials to produce ethanol, the 3D printed fence structure living materials and free cells were used as seeds to study the fermentation kinetics. Fermentation was carried out in a 50 mL anaerobic flask containing 10 mL of fermentation medium at a temperature of 30 °C and a rotation speed of 200 rpm. The initial glucose concentration was 40 g / L. like image 3 As shown, the 3D printed barrier-structured living material Saccharomyces cerevisiae exhibited lower production efficiency within 24 h compared to suspension fermentation. It may be that the 3D printing process affects the activity of the cells, which need to adapt to the new environment at the start of fermentation. But at the late stage of fermentation, the ethanol yield in the 3D printed fence structure living material reached 16.87 g / L, which was 1.3 times that of suspension fermentati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com