Oil-resistant and solvent-resistant rubber composite material, preparation method thereof and application of oil-resistant and solvent-resistant rubber composite material in cable

A composite material and solvent-resistant technology, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of oil and solvent resistance that need to be further improved, achieve good processing performance, simple preparation method, and improve the effect of oil and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

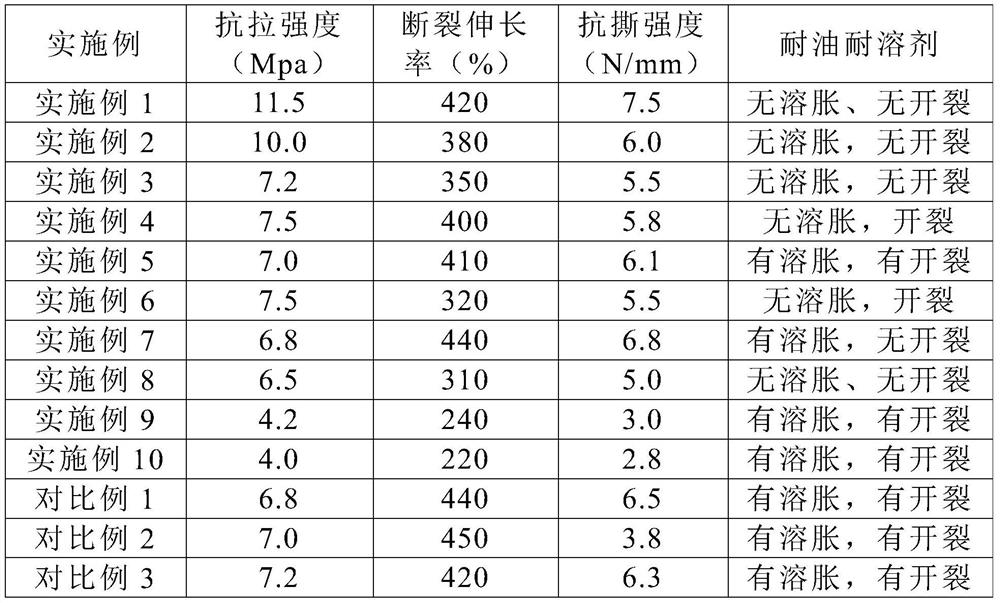

Examples

Embodiment 1

[0024] S1. Raw materials: 95 parts of ternary copolymerized chloroether rubber, 10 parts of nitrile rubber, 15 parts of reinforcing agent, 30 parts of Xiangwei silica, 15 parts of barium sulfate powder, 4 parts of magnesium oxide, 8 parts of calcium carbonate , 3 parts of antioxidant, 1 part of 2,4,6-trithiol thiotriazine;

[0025] Among them, the chlorine content of the ternary copolymerized chloroether rubber is 25%, and the Mooney viscosity is ML 1+4 100℃ is 65;

[0026] The CAN content in nitrile rubber is 33-43%, Mooney viscosity ML 1+4 100℃ is 55;

[0027] Reinforcing agent is silicon dioxide content greater than 90%, specific surface area is 181m 2 / g of precipitated silica;

[0028] The particle size of barium sulfate powder is 3 μm;

[0029] The antioxidant is NBC.

[0030] S2, ternary copolymerized chloroether rubber, nitrile rubber, reinforcing agent, phase guard silica, barium sulfate powder, magnesium oxide, calcium carbonate, anti-aging agent are put into...

Embodiment 2

[0035] S1. Raw materials: 80 parts of ternary copolymerized chloroether rubber, 1 part of nitrile rubber, 10 parts of reinforcing agent, 20 parts of Xiangwei silica, 5 parts of barium sulfate powder, 3 parts of magnesium oxide, 5 parts of calcium carbonate , 1 part of antioxidant, 0.5 part of 2,4,6-trithiol thiotriazine;

[0036] Among them, the chlorine content of the ternary copolymerized chloroether rubber is 24%, and the Mooney viscosity is ML 1+4 100℃ is 55;

[0037] The CAN content in nitrile rubber is 33%, Mooney viscosity ML 1+4 100℃ is 40;

[0038] Reinforcing agent is silicon dioxide content greater than 90%, specific surface area is 161m 2 / g of precipitated silica;

[0039] The particle size of barium sulfate powder is 2μm;

[0040] The antioxidant is NBC.

[0041] S2. Put the ternary copolymerized chloroether rubber, nitrile rubber, reinforcing agent, phase guard silica, barium sulfate powder, magnesium oxide, calcium carbonate, and anti-aging agent into a...

Embodiment 3

[0046] S1. Configuration raw materials: 100 parts of ternary copolymerized chloroether rubber, 20 parts of nitrile rubber, 30 parts of reinforcing agent, 40 parts of Xiangwei silica, 30 parts of barium sulfate powder, 5 parts of magnesium oxide, 10 parts of calcium carbonate , 5 parts of antioxidant, 2 parts of 2,4,6-trithiol thiotriazine;

[0047] Among them, the chlorine content of the ternary copolymerized chloroether rubber is 27%, and the Mooney viscosity is ML 1+4 100℃ is 85;

[0048] The CAN content in nitrile rubber is 43%, Mooney viscosity ML 1+4 100℃ is 70;

[0049] Reinforcing agent is silicon dioxide content greater than 90%, specific surface area is 190m 2 / g of precipitated silica;

[0050] The particle size of barium sulfate powder is 5μm;

[0051] The antioxidant is NBC.

[0052] S2. Put ternary copolymerized chloroether rubber, nitrile rubber, reinforcing agent, phase-protected silica, barium sulfate powder, magnesium oxide, calcium carbonate, and anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com