Column switch production line control method and system

An on-column switch and control method technology, applied in the directions of comprehensive factory control, electric/hybrid power, sorting, etc., can solve the problems affecting the efficiency of production enterprises, difficulty, and the inability to effectively form a unified and coordinated work flow, so as to avoid manual labor. The effect of warehouse work and production capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the specific embodiments and the accompanying drawings. It should be understood that these descriptions are exemplary only and are not intended to limit the scope of the invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concepts of the present invention.

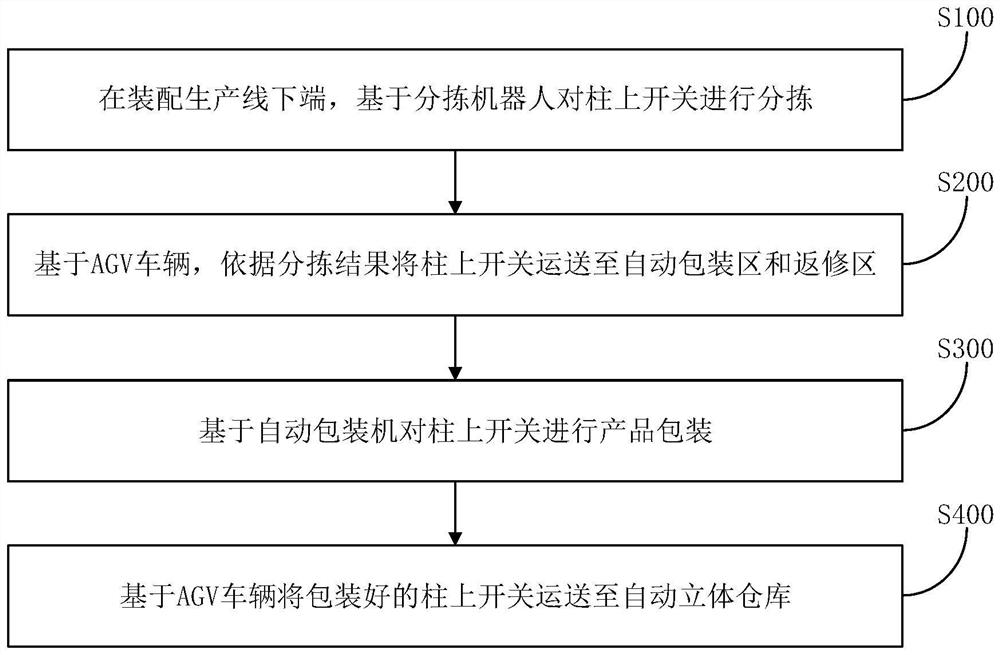

[0036] Please refer to figure 1 , a first aspect of the embodiments of the present invention provides a method for controlling a switch production line on a column, comprising the following steps:

[0037] In step S100, at the lower end of the assembly line, the on-column switches are sorted based on a sorting robot.

[0038] In step S200, based on the AGV vehicle, the on-column switch is transported to the automatic packaging area and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com