Ultra-miniature bearing inner ring polishing device

A polishing device and miniature bearing technology, which is applied in the field of bearing processing, can solve problems such as scratches on the surface of workpieces, damage to workpieces, unfavorable abrasives for long-term repeated use, etc., and achieve a strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

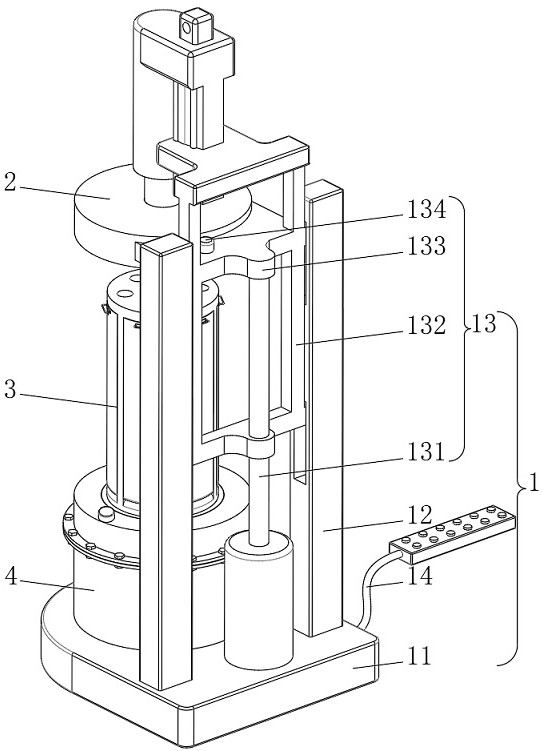

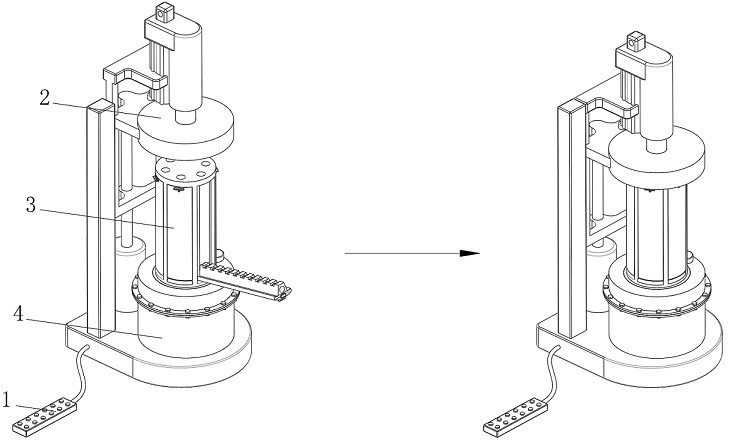

[0044] see Figure 1-12 , the present invention provides a technical solution: a superminiature bearing inner ring polishing device, comprising:

[0045] The operating body 1 includes a drive base 11 , a slideway 12 fixedly connected to the top of the drive base 11 , and a lifter 13 slidably installed inside the slideway 12 ;

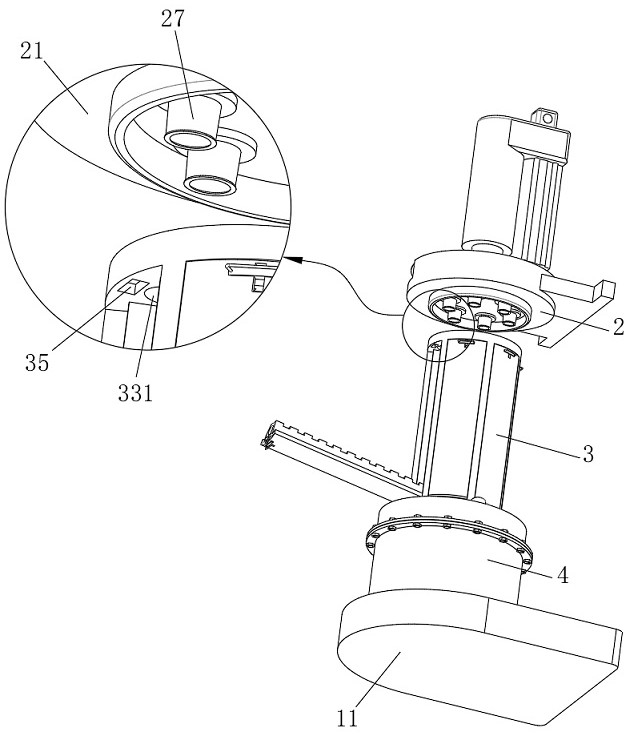

[0046] The extrusion part 2, the extrusion part 2 includes a high pressure box 21, which is detachably and fixedly connected to the outside of the lifting member 13, and is slidably connected to the piston disc 22 on the inner wall of the high pressure box 21. Open and close the plate assembly 24 on the outside of the rotating reset lever 23, and set the shutter assembly 25 on the top of the inner wall of the high-pressure tank 21;

[0047] The placing part 3, the placing part 3 comprises a rotating column 31, an abrasive grain hole 32 opened inside the rotating column 31, the top of the abrasive grain hole 32 is adapted to the bottom of the high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com