Movable self-discharging sand hopper device

A mobile, sand bucket technology, applied in the field of mold casting, can solve the problem of uneven material distribution, achieve the effect of improving uniformity, improving discharge efficiency, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

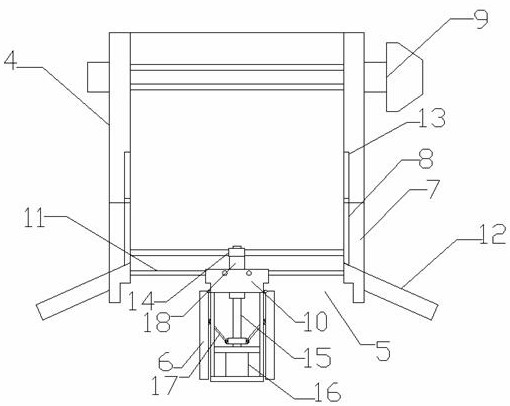

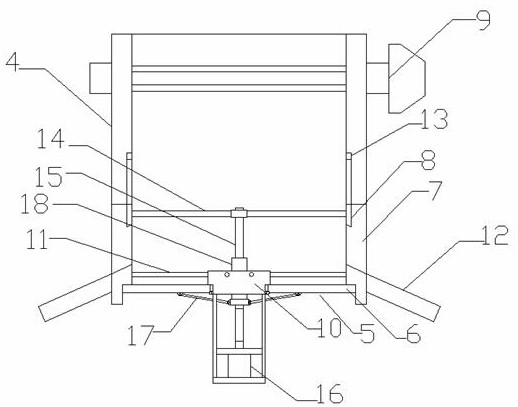

[0024] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments, which are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

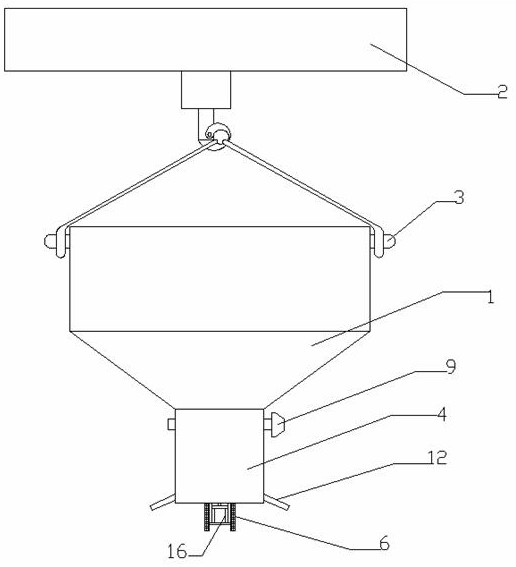

[0025] like figure 1 As shown, this embodiment provides a mobile self-unloading sand hopper device, including a sand hopper 1, a hoisting crane 2 is arranged above the sand hopper 1, a lifting ring 3 is arranged on the outer side wall of the sand hopper 1, and the lower end of the steel rope and the lifting ring 3 can be connected After dismantling the connection, the hoisting crane 2 hoists the sand bucket 1 through the steel wire, so that the sand bucket 1 can be moved.

[0026] The lower end of the sand hopper 1 is provided with a discharge pipe 4. The sand in the sand hopper 1 is discharged through the discharge pipe. The upper end of the discharge pipe 4 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com