Medium and low temperature electrothermal film of inorganic non-metallic material and preparation method thereof

An inorganic non-metallic, electrothermal film technology, used in electrothermal devices, ohmic resistance heating, heating element materials, etc., can solve the problems of discontinuous film, poor uniformity, aging, etc., and achieve energy saving, environmental protection, and good square resistance uniformity in the preparation process. , the effect of stable heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In one embodiment, the method for preparing a low-temperature electrothermal film in an inorganic non-metallic material includes:

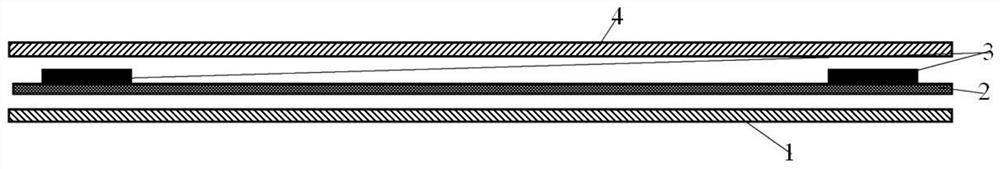

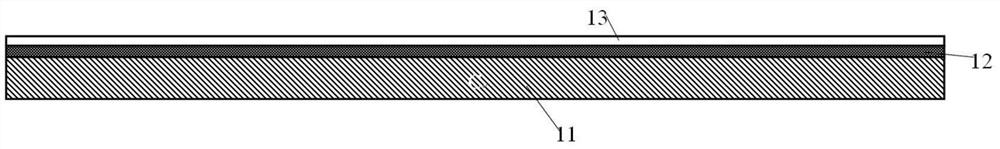

[0057] Inorganic non-metallic materials (such as Sn) on single-layer hard-coated PET (substrate layer) x Sb (1-x) O, Zn x Ga (1-x) O, ZnO x S (1-x) , InO x S (1-x) , Sn x In (1-x) O, Zn x Mg (1-x) O, Zn x Al (1-x) O and SiC doping, etc.) magnetron sputtering coating, by adjusting the X value: that is, adjusting its composition ratio to make its resistivity within 10 -3 Ω.m~10 -6 Between Ω.m, the thickness reaches 10 to 100 nanometers, and the square resistance is about 200 to 1000Ω; secondly, a copper foil with a specification of 0.01 to 1 mm (thickness) * 3 to 25 mm (width) is laid on the surface of the inorganic non-metallic material film as a conductive electrode; finally, the conductive electrode and the inorganic non-metallic material film on the surface are covered with an insulating film as a protective film, and the th...

Embodiment 1

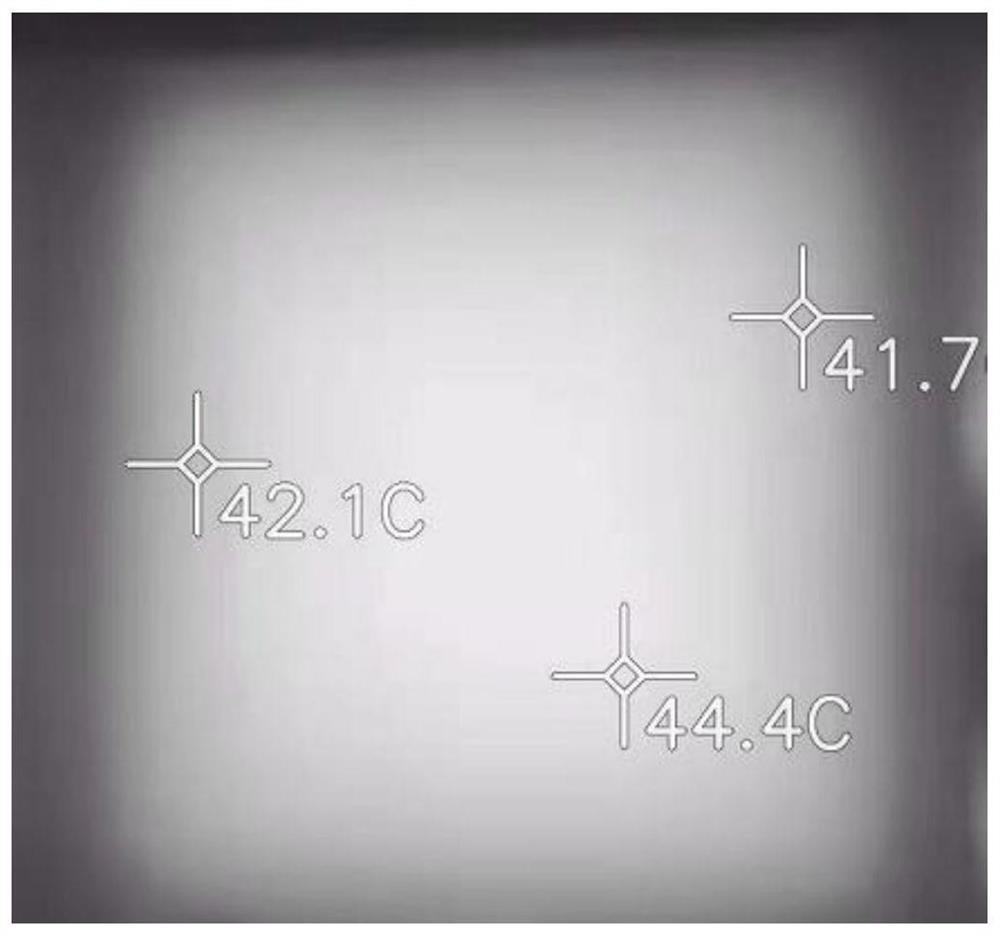

[0060] Pre-coat 2μm thick water-based polymer material on the 188μm thick PET original film substrate (roughness 10 to 100), dry and coat with resin, and then cure by UV irradiation to improve the hardness of the film layer, so that the hardness reaches The pencil hardness is 2H; then magnetron sputtering coating is performed on the hard coating layer, the coating material is ITO, the thickness of the heating layer is 20nm, and the resistivity of the heating layer is 9*10 -6 Ω.m, the square resistance is 450Ω; finally, the Cu electrode is laid and the insulating PET protective film is applied, where the thickness of the Cu electrode and the PET protective film are 0.05mm and 0.15mm respectively, the film pressure is 0.5MPa, and the film temperature is 135 °C. Finally, a sealed and insulated electric heating film is prepared. The specification of the electric heating film is 600mm*600mm. When the heating voltage is 220V, the power density of the electric heating film is 350W / sq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com