Protection device of permanent magnet synchronous motor control cabinet

A permanent magnet synchronization and protective device technology, which is applied in the direction of AC motor control, substation/power distribution device casing, control system, etc., can solve problems such as difficult temperature drop, leakage, and burnout of electrical components, so as to reduce power loss and improve Lifespan, effect of preventing frostbite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

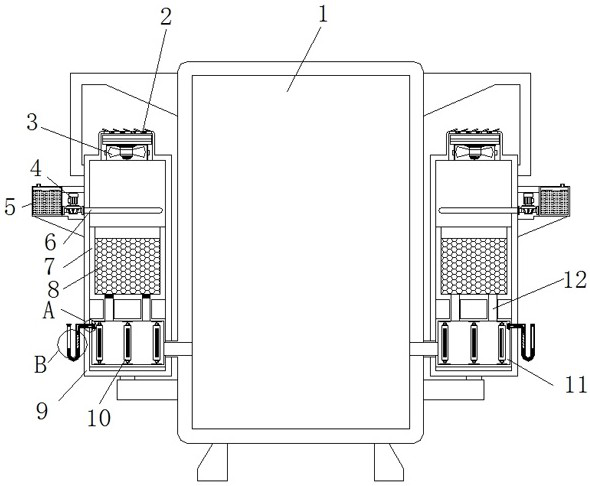

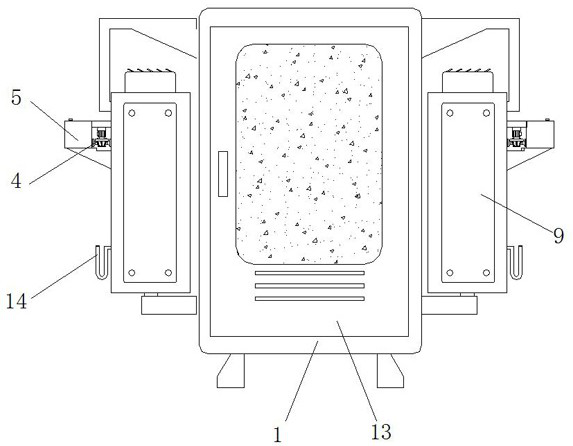

[0037] Example 1, as Figure 1-6 As shown, in the process of using the electrical cabinet in summer, the fan 3 is first started, and then the fan 3 discharges the outside air to the inside of the electrical cabinet shell 1, and then when the air passes through the cooling pipe 6, the water pump 4 starts to extract the interior of the liquid storage tank 5 The cooling liquid circulates through the cooling pipe 6, and then absorbs the temperature inside the air, and then the cooled air enters the interior of the desiccant 8, and the desiccant 8 absorbs the moisture inside the air, and finally the air enters the air through the connecting bin 11. The inside of the electrical cabinet shell 1, and the air inside the electrical cabinet shell 1 is exhausted to the outside from the exhaust port at one end of the warehouse door 13, so as to ventilate the inside of the electrical cabinet shell 1.

Embodiment 2

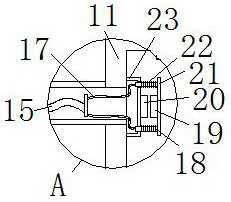

[0038] Example 2, as Figure 1-5As shown in the figure, when it is in winter, the U-shaped pipe 14 is cooled under the influence of the external cold air. Since the interior of the U-shaped pipe 14 is in a sealed state, the air on the left side of the U-shaped pipe 14 shrinks when cooled, so that the U-shaped pipe 14 is in a sealed state. The pressure on the left side inside the shaped tube 14 becomes smaller, which in turn drives the liquid level on the left side to rise. At this time, the wooden floating plate 16 on the right side moves down with the liquid level and pulls the connecting rope A15, and then the connecting rope A15 is pulled by the connecting rope B17. Two sets of sliding rods 18 make the spring 22 compress, and at the same time, the contact piece A19 and the contact piece B20 are in contact, so that the circuit is connected to start the heating tube 10, and then the heating tube 10 heats the interior of the connection chamber 11. When the air flows from the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com