Press centering test method

A testing method and press technology, which is applied in the field of powder metallurgy, can solve the problems of affecting the pressing precision, little practical significance, unsuitable for small amount of processing, etc., and achieve the effect of improving the pressing precision, saving post-processing procedures, and avoiding the partial load of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described below by specific embodiments, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

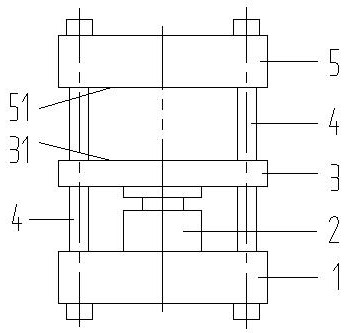

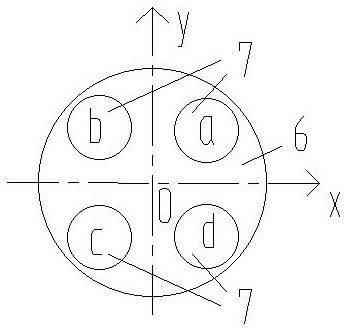

[0034] The invention provides a press centering test method, such as Figure 1 to Figure 5 shown.

[0035] The press centering test method includes the following steps:

[0036] 1) Under static conditions, adjust the parallelism of the upper and lower worktables of the press;

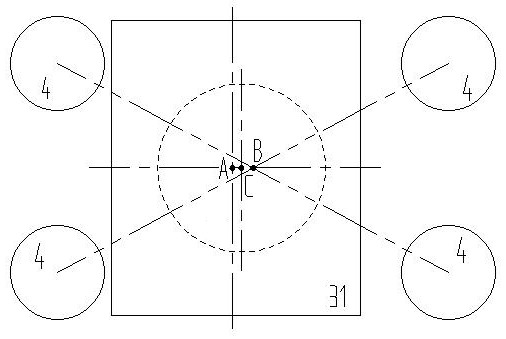

[0037] 2) On the table of the press, measure and determine the geometric center of the table, and mark it as point A of the center of the table;

[0038] 3) On the working table of the press, measure and determine the geometric center of the four-column, and mark it as point B of the center of the four-column;

[0039] 4) On the working table of the press, take the center point C of the two points A and B as the base point, and test under the working pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com