Sensor protection device and sensor assembling method adopting same

A protection device and sensor technology, applied in the field of sensor assembly and sensor protection device, can solve the problems of winding or breakage, inability to restore, inability to accurately measure the explosion shock wave load, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

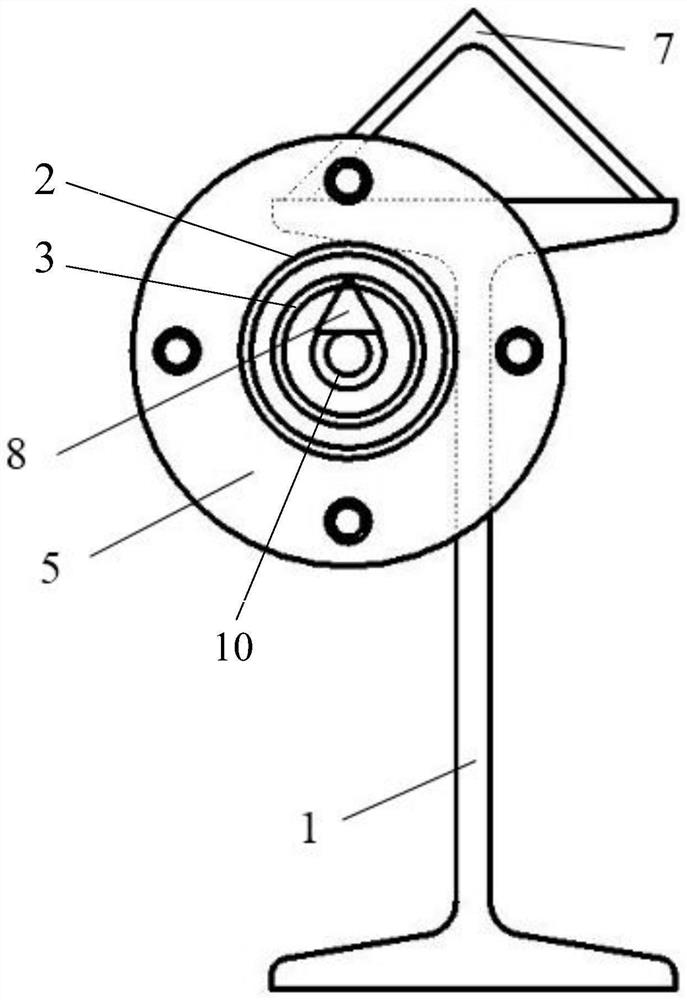

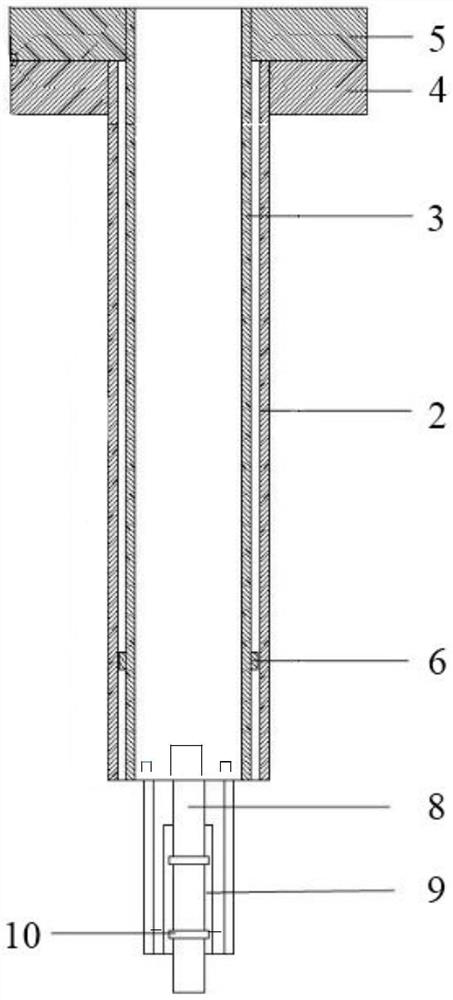

[0045] A sensor protection device such as figure 1 and figure 2As shown, the device includes: an inner pipe 3, a casing 2, an inner pipe flange 5, a casing flange 4 and a sensor fixing member. The inner pipe flange 5 is fixedly installed on one end of the inner pipe 3, the casing flange 4 is fixedly installed on one end of the casing 2, and after the inner pipe flange 5 is fixedly connected with the casing flange 4, the inner pipe 3 can pass through Set on the sleeve 2, the sensor fixing part is used to fix the sensor, one end is fixedly installed inside the end of the inner tube 3 away from the inner tube flange 5, and the other end extends out of the inner tube 3 and faces away from the inner tube 3 along the axis direction of the inner tube 3. One end of the pipe flange 5 extends; the inner pipe 3, the central through hole of the inner pipe flange 5 and the central through hole of the sleeve flange 4 are used for passing the transmission cable of the sensor.

[0046] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com