Wool coagulator

A wool condensing device and condensing technology, applied in the direction of fiber opening and cleaning machines, etc., can solve problems such as unfavorable textile production, low efficiency, and textile entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment the present invention is described in further detail:

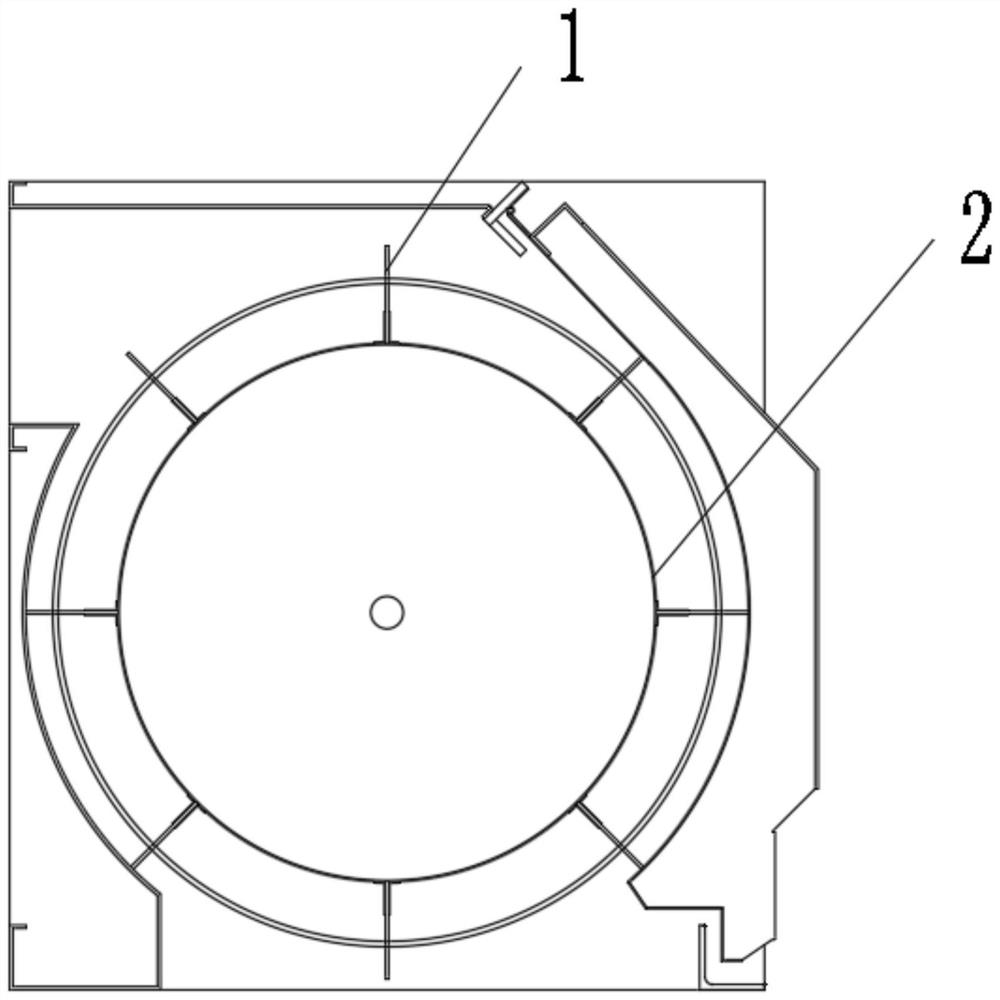

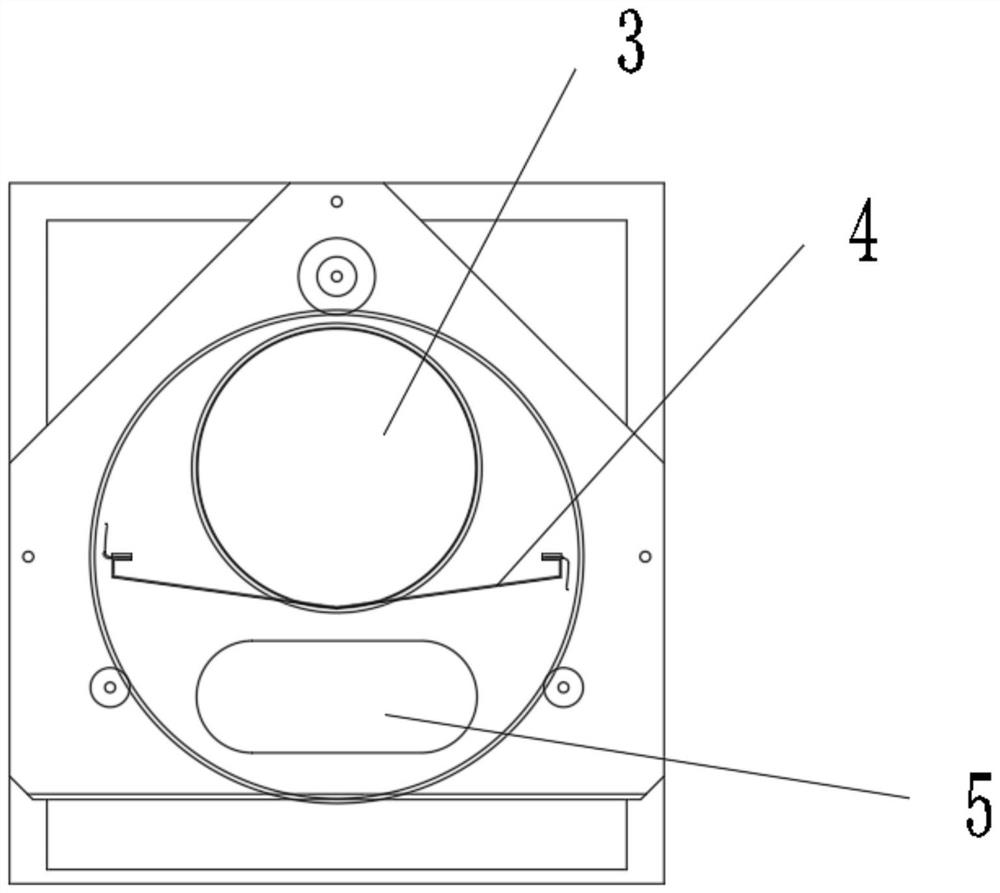

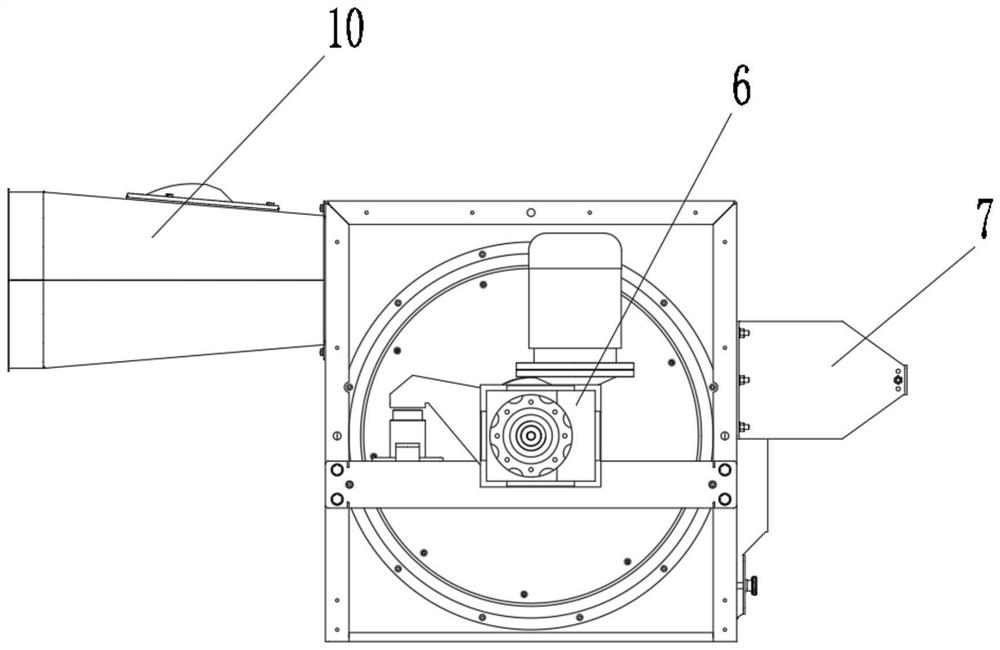

[0031] A hair condenser, comprising a shell, a feed port 10, a dust cage, a dust cage 2, a reducer 6, an air suction port 3, a windshield 4 and an air supply port;

[0032] The shell is a cuboid, with a feed inlet 10 on the top of the front, a reducer 6 on the first side, an air suction port 3 on the second side, a dust cage inside the shell, and a dust cage inside the dust cage. The placed cylindrical dust cage 2 is provided with a windshield 4 inside the dust cage 2 .

[0033] The length of the dust cage 2 is the same as that of the casing;

[0034] One side of the dust cage 2 is provided with a rotating plate, and the center of the rotating plate is provided with a connecting shaft connected with the reducer 6;

[0035] One end of the windshield 4 is fixed on the connecting shaft through a bearing, and the other end is fixedly connected to the second side of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com