Threshing device

A technology of threshing device and threshing chamber, which is applied in threshing equipment, application, agricultural machinery and implements, etc. It can solve problems such as entanglement of grain stalks, reduction of threshing performance and conveying performance, and deformation of shielding plates, so as to increase the amount of grain leakage , Improve rigidity and prevent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

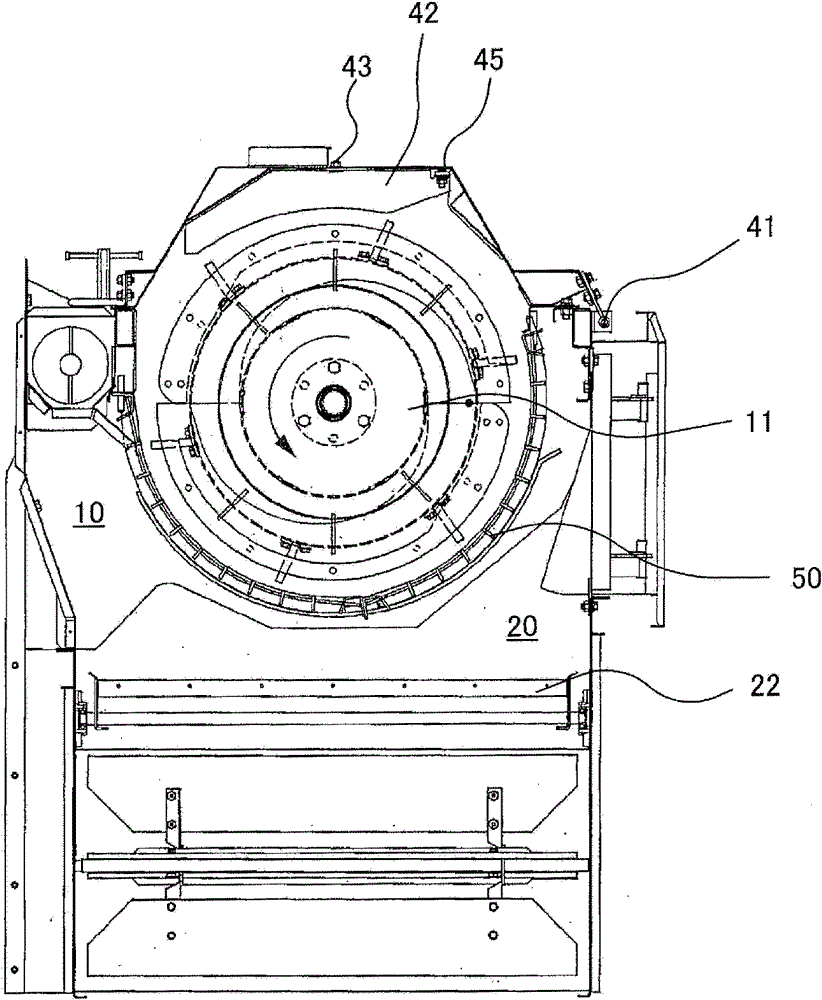

[0135] Next, the barrel 11 of 2nd Embodiment is demonstrated in detail. In addition, the same reference numerals are assigned to the same members, and overlapping explanations are omitted.

[0136] The distance between the threshing gears 78A of the plate 78 and the distance between the threshing gears 79A of the plate 79 attached adjacent to the outer peripheral surface of the cylindrical part 17 is to efficiently carry the grain stalks backward and improve the filtration rate from the threshing net 50 . ,Such as Figure 19 As shown, the distance between the processing teeth 78A and 79A erected on the front side of the plates 78 and 79 is twice the interval of the processing teeth 78A and 79A erected on the rear side of the plates 78 and 79 . In addition, about the processing teeth 78A and 79A of the plates 78 and 79 that are adjacently installed, the phases are shifted on the front side, and the processing teeth 78A and the processing teeth 79A are arranged so as not to ove...

no. 3 Embodiment approach

[0138] Next, the barrel 11 of 3rd Embodiment is demonstrated in detail. In addition, the same code|symbol is attached|subjected to the same member, and repeated description is abbreviate|omitted.

[0139] In order to prevent the threshing teeth 88 and 89 from being entangled by the supplied grain stalks, improve the threshing performance, and carry out the conveyance of the grain stalks to the rear efficiently, such as Figure 20 As shown, on the front side of the cylinder part 17, it is alternately arranged at intervals of 90 degrees in the circumferential direction: a plate 88 with a threshing tooth 88A is erected; and a plate 89 with a threshing tooth 89A is erected. The rear side part is provided alternately at intervals of 60° in the circumferential direction: the plate 88 provided with the processing gear 88A standing up; and the plate 89 provided with the processing gear 89A standing up. In addition, in 3rd Embodiment, the interval of 88 A of processing teeth and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com