Broadband silencer for fuel cell vehicle

A technology for fuel cell vehicles and mufflers, which is applied to fuel cells, components of pumping devices for elastic fluids, electrochemical generators, etc., can solve the problems of long cycle, high cost, slow response, etc., and widen the acoustic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

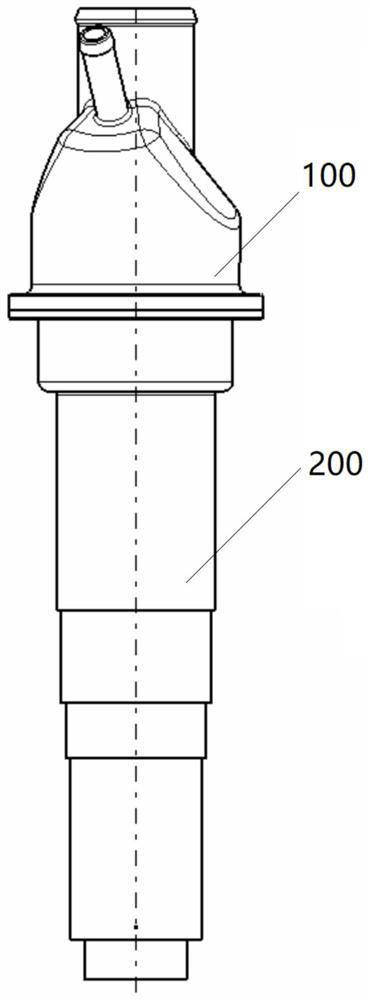

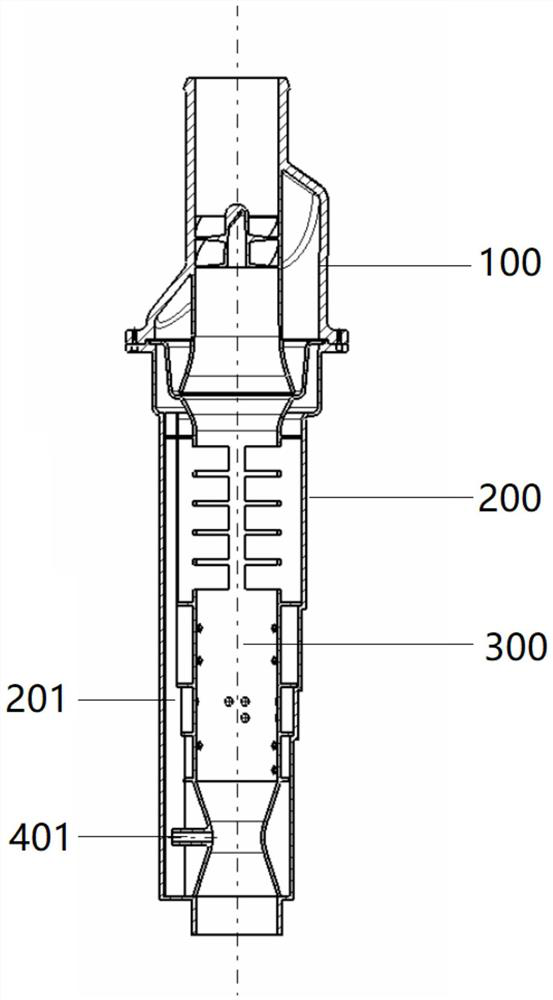

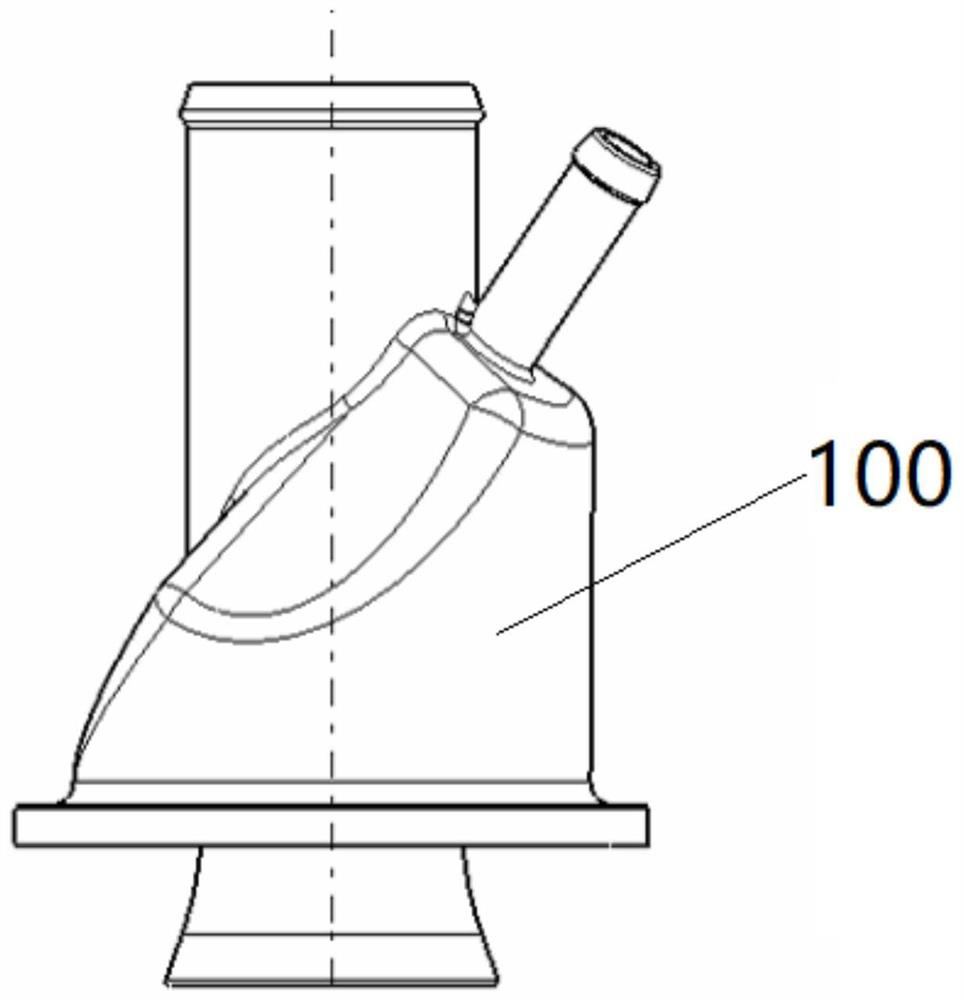

[0039] like figure 1 , 2 , a broadband muffler for fuel cell vehicles, comprising a first casing 100, a second casing 200 and an inner tube 300, the first casing 100 and the second casing 200 are connected to form a sealed cavity, and the inner The tube 300 is installed in the sealed cavity formed by the first casing 100 and the second casing 200 , and the inner tube 300 has holes or grooves to form a plurality of sound-absorbing structures in the sealed cavity.

[0040] like Image 6 , 7 , the second shell 200 is a stepped cylindrical pipe, and the second shell 200 is provided with a water collecting tank 201 along its side. water in each chamber, thereby preventing the failure of each chamber of the muffler due to accumulation of water. One end of the exhaust port of the inner intubation pipe 300 is connected with a venturi pipe 400 , and a drain pipe 401 communicated with the water collecting tank 201 is provided in the center of the venturi pipe 400 .

[0041] like ...

Embodiment 2

[0049] In a specific muffler design, the sound-absorbing cotton 1 (OX-Pan) and the sound-absorbing cotton 2 (Basotec G+ of BASF) are integrated in the muffler. The sound-absorbing cotton structure is as follows: Figure 10-12 shown. The specific process parameters of each muffler structure are as follows: Figure 15 , the volume of C1 is 0.27L, the square hole is opened, and the opening rate is 0.66, which is used to fill the sound-absorbing cotton. The function of the sound-absorbing cotton is 1000-8000Hz; 6 holes, the opening rate is 0.014, and the corresponding silencing frequency is 1000Hz; the volume of C3 is 0.044L, and 11 circular holes with a diameter of 5mm are opened, the hole rate is 0.045, and the corresponding sound silencing frequency is 1120Hz; C4 The volume of C5 is 0.027L, 5 circular holes with a diameter of 5mm are opened, the opening rate is 0.022, and the corresponding silencing frequency is 1420Hz; the volume of C5 is 0.13L, the cavity is not perforated, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com