Transport vehicle for steel pipes in tunnel

A technology for in-tunnel and transport vehicles, applied in tunnels, underground transportation, tunnel lining and other directions, can solve the problems of easy pressure explosion and damage of oil cylinders, and achieve the effect of eliminating hidden dangers and avoiding eccentric wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

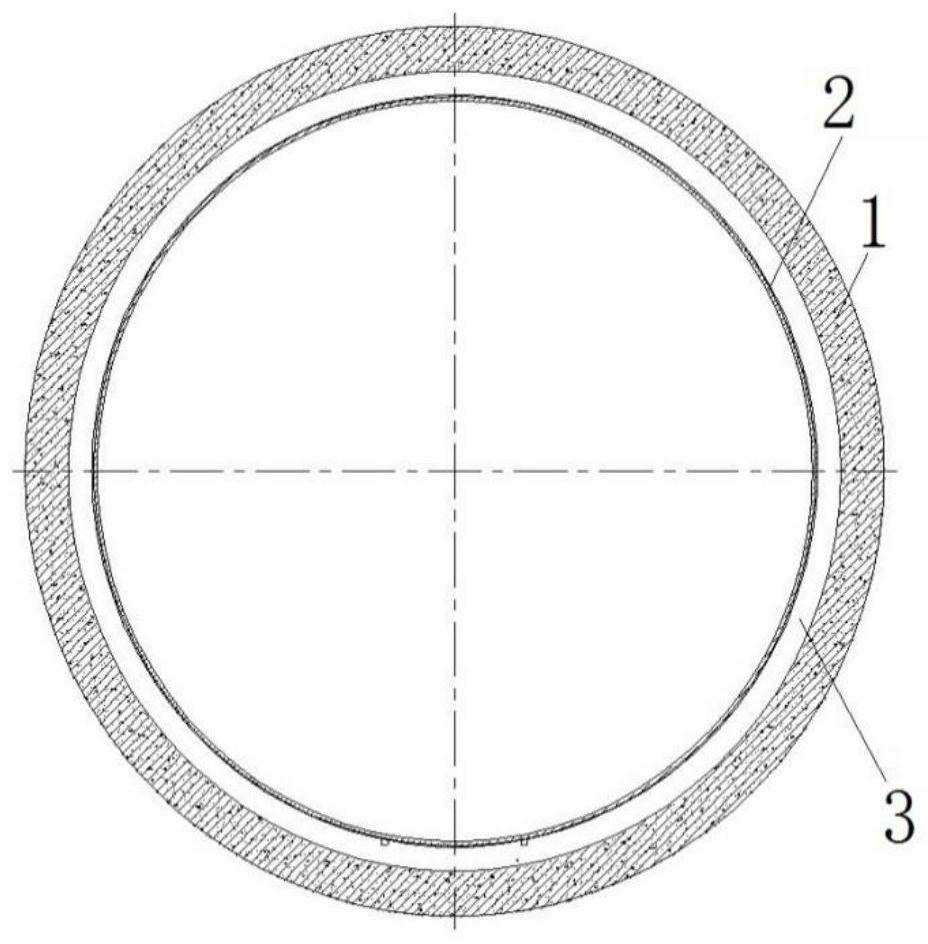

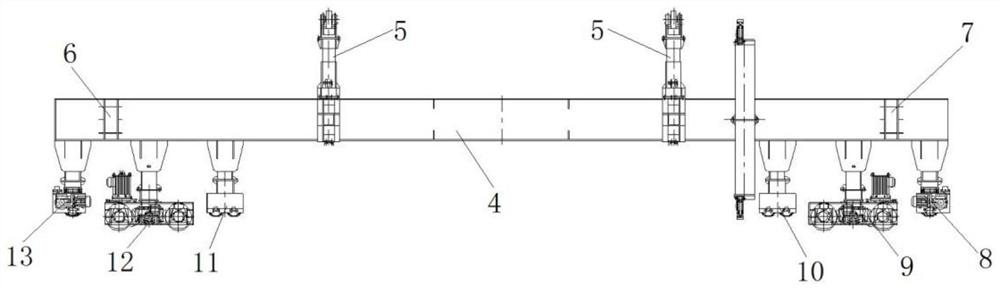

[0041] like Figure 2 to Figure 12 As shown in the figure, the steel pipe transport vehicle in the tunnel (hereinafter referred to as the transport vehicle) is used to carry the steel pipe, and transport the steel pipe in the tunnel to the place where the steel pipe has been laid for docking.

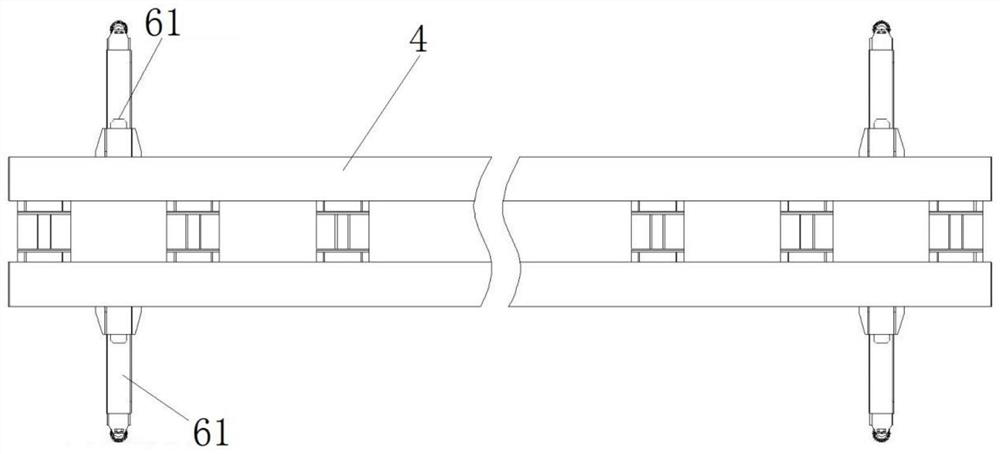

[0042] The transport vehicle includes a main beam 4, and the front and rear ends of the main beam 4 are respectively equipped with lifting and traveling wheel assemblies. The lifting and traveling wheel assemblies support the main beam 4 and drive the main beam 4 to move back and forth. Among them, the head and tail of the main beam 4 are only relative concepts. The lifting and traveling wheel assembly at one end of the main beam 4 includes a first active rubber wheel group 8, a first steel wheel group 9 and a first driven rubber wheel group 10 that can be lifted independently. The driven rubber wheel set 10 is disposed on the front and rear sides of the first steel wheel set 9 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com