Bio-enzyme synthesis method and application of cosmetic-grade hexose-6-phosphoric acid composition

A cosmetic-grade, bio-enzymatic technology, applied in the field of biological composition preparation, can solve problems such as different biochemical metabolism pathways and differences in anti-aging functional components, and achieve the effects of reducing process difficulty, saving production costs, and reducing process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

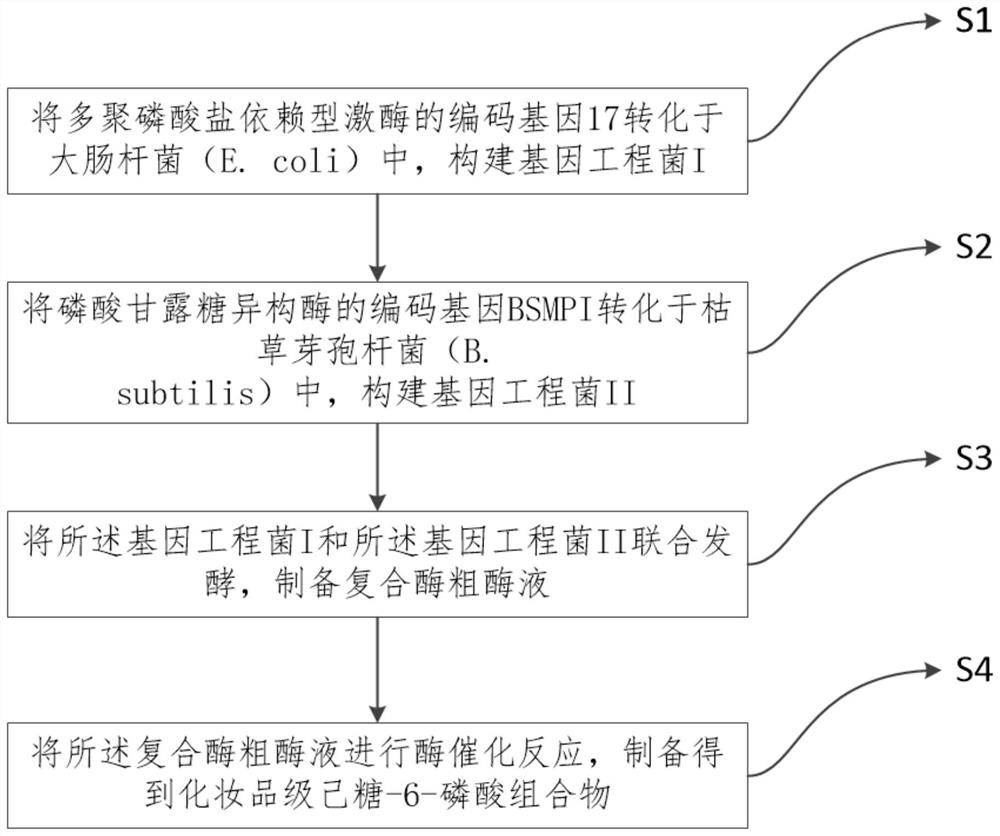

Method used

Image

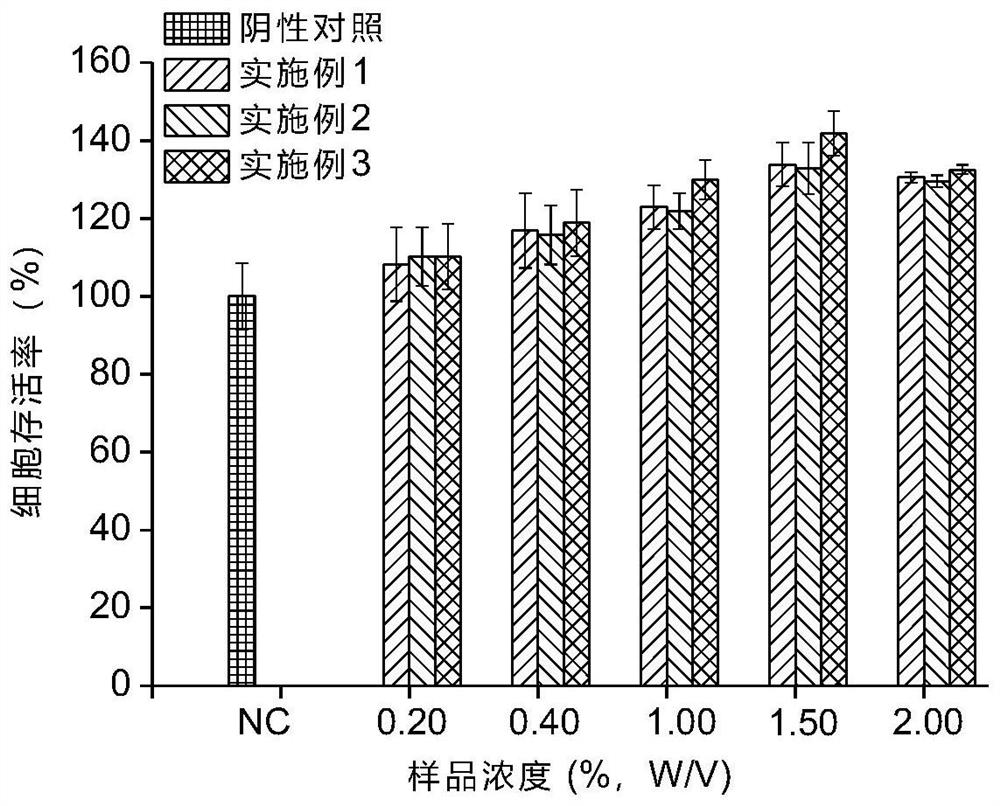

Examples

Embodiment 1

[0066] Embodiment 1: Genetically engineered bacteria I prepare hexokinase crude enzyme liquid by fermentation

[0067] (1) Bacterial fermentation:

[0068] The genetically engineered bacteria I capable of heterologously expressing polyphosphate-dependent mannokinase were inoculated into 50 mL of LB liquid medium (50 mg / L Kana), fermented for 8 h, at a temperature of 37 °C, and at a stirring speed of 180 rpm; The fermentation product was inoculated into 2L of LB liquid medium (50mg / L Kana) according to 1‰, and the air flow was controlled to be 4Nm under the conditions of temperature 30℃ and pH 7 3 / h; after the dissolved oxygen in the fermentation system is stabilized at 10%, an inducer IPTG is added, and the above fermentation conditions are maintained for 12 hours to obtain a fermentation broth.

[0069] (2) Preparation of crude enzyme solution:

[0070] The fermentation broth was centrifuged at 4°C and a rotating speed of 8000rpm to collect the cells, and the cells were re...

Embodiment 2

[0076] Example 2: Preparation of phosphate mannose isomerase crude enzyme liquid by fermentation of genetically engineered bacteria II

[0077] Bacterial fermentation:

[0078] The genetically engineered bacteria II capable of heterologously expressing phosphomannose isomerase was inoculated into 50 mL of LB liquid medium (50 mg / L Kana), and fermented for 8 h at a temperature of 37°C and a stirring speed of 180 rpm; 0.5‰ was inoculated into 2L of LB liquid medium (50mg / L Kana), and the air flow was controlled to be 4Nm under the conditions of temperature of 30℃ and pH of 7 3 / h; after the dissolved oxygen in the fermentation system is stabilized at 10%, an inducer IPTG is added, and the above fermentation conditions are maintained for 12 hours to obtain a fermentation broth.

[0079] Preparation of crude enzyme solution:

[0080] Carry out according to the method described in Example 1.

[0082] Accurately weigh 1mL of the crude enzyme solut...

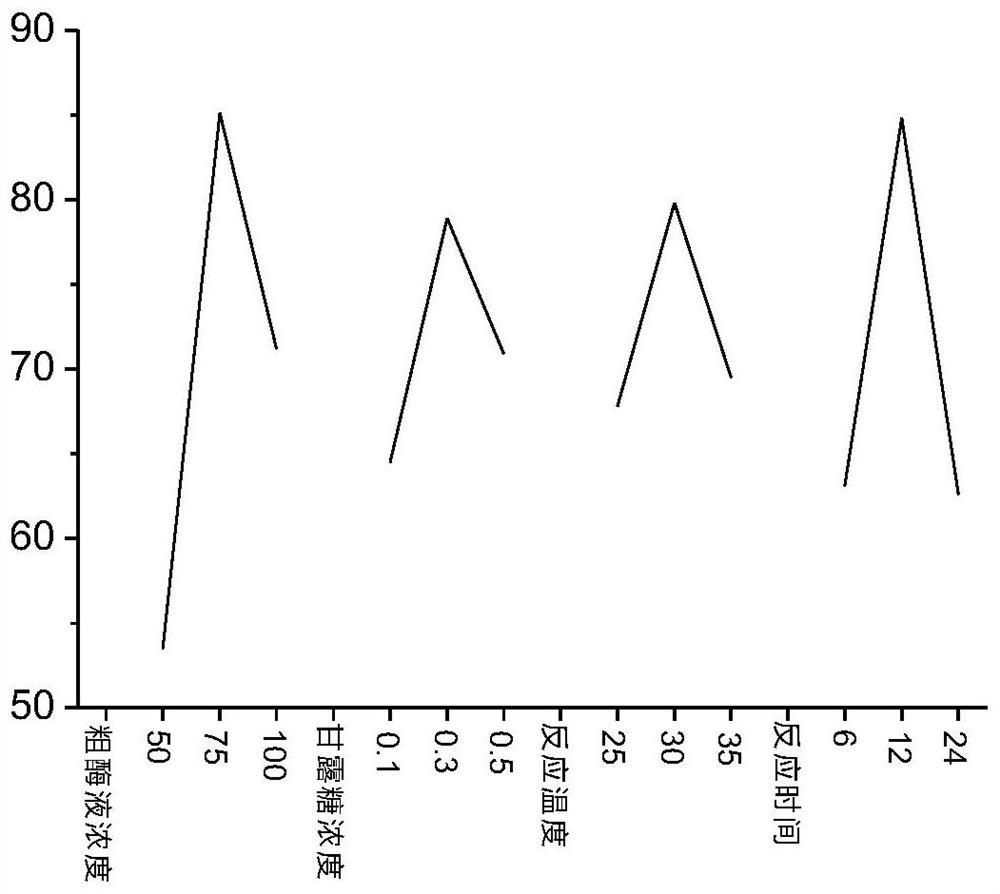

Embodiment 3

[0086] Embodiment three: the joint fermentation preparation of mixed enzyme crude enzyme liquid

[0087] (1) Bacterial fermentation:

[0088]The genetically engineered bacteria I capable of heterologously expressing polyphosphate-dependent mannokinase was inoculated into 50 mL of LB liquid culture medium (50 mg / L Kana); at the same time, the heterologous expression of mannose phosphate isomer The genetically engineered bacteria II of the enzyme was inoculated into 50 mL of LB liquid medium (50 mg / LKana); the fermentation conditions of both were 37 ° C, 8 h, and 180 rpm; and then the fermentation product of the genetically engineered bacteria I was 1‰, genetically engineered The fermentation product of Bacteria II was inoculated into 2L of LB liquid medium (50mg / L Kana) according to 0.5‰, and the air flow was controlled to be 4Nm under the conditions of temperature of 30℃ and pH of 7. 3 / h; after the dissolved oxygen in the fermentation system is stabilized at 10%, an inducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com