Single-component polyurethane foam joint mixture and preparation method thereof

A technology of polyurethane foam and caulking agent, which is applied in the field of polyurethane foam caulking agent, can solve problems such as degradability and fertilization, etc., and achieve the effects of improving fertilizer utilization rate, reducing cost and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

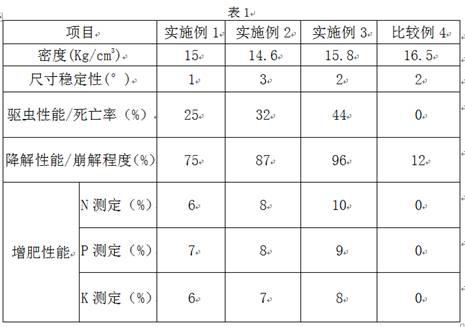

Examples

Embodiment 1

[0038] According to the proportion by weight, 0.5 part of deltamethrin and 0.5 part of permethrin are mixed in proportion, and through emulsification and microencapsulation treatment, nano-scale microcapsules mainly composed of pyrethroids are obtained; , 0.5 part of the ground camphor, 0.5 part of marigold and 1 part of the prepared nano-scale microcapsules were evenly mixed to prepare the pesticide. According to the weight distribution ratio, 0.5 part of urea formaldehyde, 0.5 part of ammonium polyphosphate and 0.5 part of potassium polyphosphate are mixed first, and after grinding, they are treated with polyethylene film to prepare long-term fertilizer.

[0039] Then, 15 parts of C14-C17 alkane liquid paraffin, 5 parts of Softcel U-100 polyether polyol, 3 parts of Arcol 1150 polyether polyol, 6 parts of PolyTHF 250 polytetrahydrofuran diol, 0.8 part of DC5357 silicone oil, 0.4 part of DC5598 silicone oil, 0.3 part of bismorpholinyl diethyl ether, 0.3 part of 1,4 dimethylpip...

Embodiment 2

[0041] According to the proportion by weight, 0.75 part of deltamethrin and 0.75 part of permethrin are mixed in proportion, and after emulsification microencapsulation treatment, the nano-scale microcapsules mainly composed of pyrethroids are obtained; , 0.75 part of the ground camphor, 0.75 part of Tian Lankui and 1.5 part of the prepared nano-scale microcapsules are mixed evenly to prepare the pesticide. Mix 1 part of urea formaldehyde, 1 part of ammonium polyphosphate and 1 part of potassium polyphosphate according to the proportion by weight, and after grinding, do polyethylene coating treatment to prepare long-acting fertilizer.

[0042] Then, 16 parts of C14-C17 alkane liquid paraffin, 7 parts of Softcel U-1000 polyether polyol, 4 parts of Arcol 1150 polyether polyol, 7 parts of PolyTHF 250 polytetrahydrofuran glycol, 1 part of DC5357 silicone oil, 0.6 part of DC5564 silicone oil, 0.45 part of bismorpholinyl diethyl ether, 0.45 part of tetramethylhexamethylene diamine, ...

Embodiment 3

[0044] According to the proportion by weight, 1 part of deltamethrin and 1 part of permethrin are mixed in proportion, and through emulsification microencapsulation treatment, the nano-scale microcapsules mainly composed of pyrethroid compounds are obtained; , 1 part of the ground marigold, 1 part of Tian Lankui and 2 parts of the prepared nano-scale microcapsules are evenly mixed to prepare the pesticide. 1.5 parts of urea formaldehyde, 1.5 parts of ammonium polyphosphate and 1.5 parts of potassium polyphosphate are mixed according to the proportion by weight, and after grinding, they are treated with polyethylene coating to obtain a long-term fertilizer.

[0045]Then, 17 parts of C14-C17 alkane liquid paraffin, 9 parts of Softcel U-1000 polyether polyol, 5 parts of Arcol 1150 polyether polyol, 8 parts of PolyTHF 250 polytetrahydrofuran glycol, 1.2 parts of DC5598 silicone oil, 0.8 part of DC5564 silicone oil, 0.6 part of 1,4-dimethylpiperazine, 0.6 part of tetramethylhexamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com