Molten-state lithium battery negative electrode material, preparation method and all-solid-state lithium battery

A negative electrode material, lithium battery technology, applied in battery electrodes, lithium storage batteries, negative electrodes, etc., can solve the problems of reduced interface resistance and limited effect, achieve high charge and discharge capacity, and improve interface wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

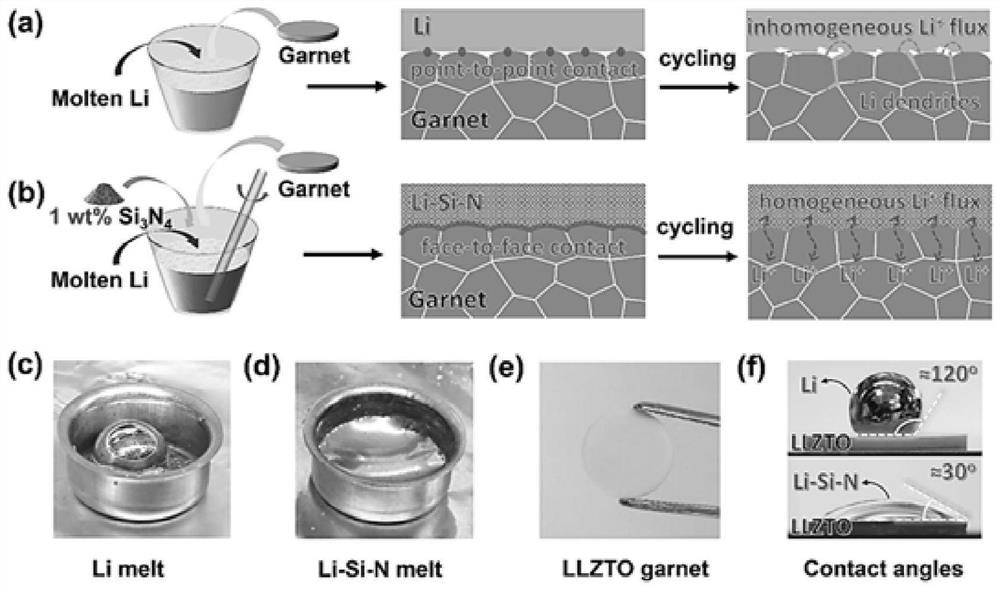

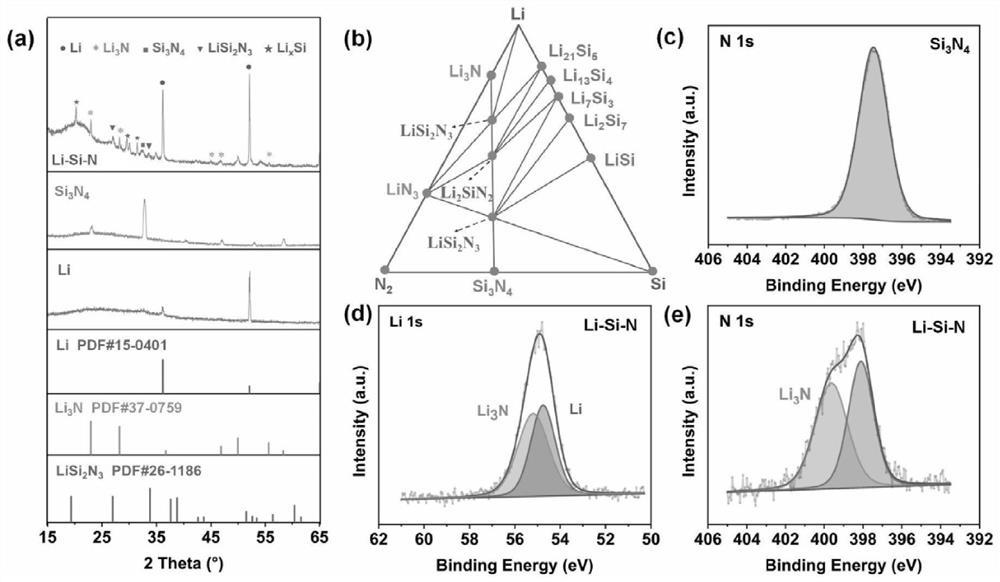

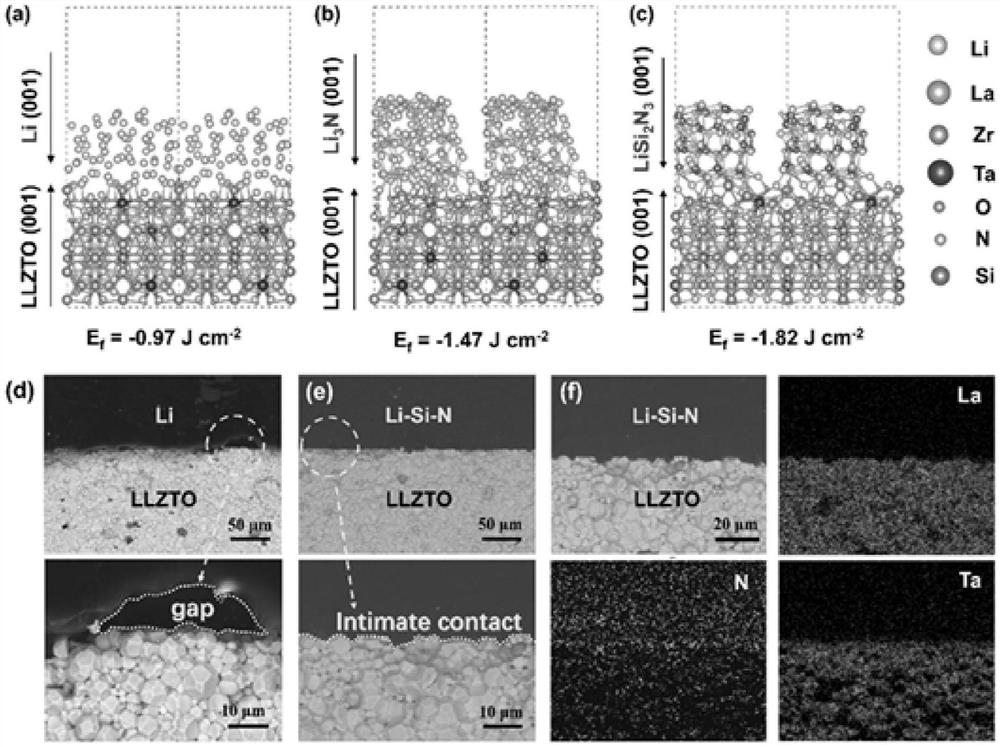

[0042] All-solid-state lithium batteries (ASSBs) have the advantages of safety and high energy density, and have become the only way for the development of lithium batteries in the future. Among different types of electrolytes, garnet-type electrolytes are considered to be one of the most promising electrolytes for solid-state batteries due to their high ionic conductivity and good electrochemical stability to metallic lithium. However, garnet-type electrolytes face two important challenges, one is the poor contact between the electrolyte and the lithium anode, which leads to a large interfacial impedance, and the other is that the lithium dendrites pierce the electrolyte and cause a short circuit of the battery.

[0043] Preparation of LLZTO Electrolyte Sheets, Molten Li and Molten Li-Si-N

[0044] (1) Preparation of LLZTO electrolyte sheet

[0045] LLZTO electrolyte sheets were prepared by traditional solid-phase method. First weigh LiOH·H according to the stoichiometric p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com