Roadbed supporting structure

A technology for supporting structures and roadbeds, applied in infrastructure engineering, roads, roads, etc., can solve problems such as longer engineering cycles, and achieve the effects of improving bearing effect, increasing strength, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

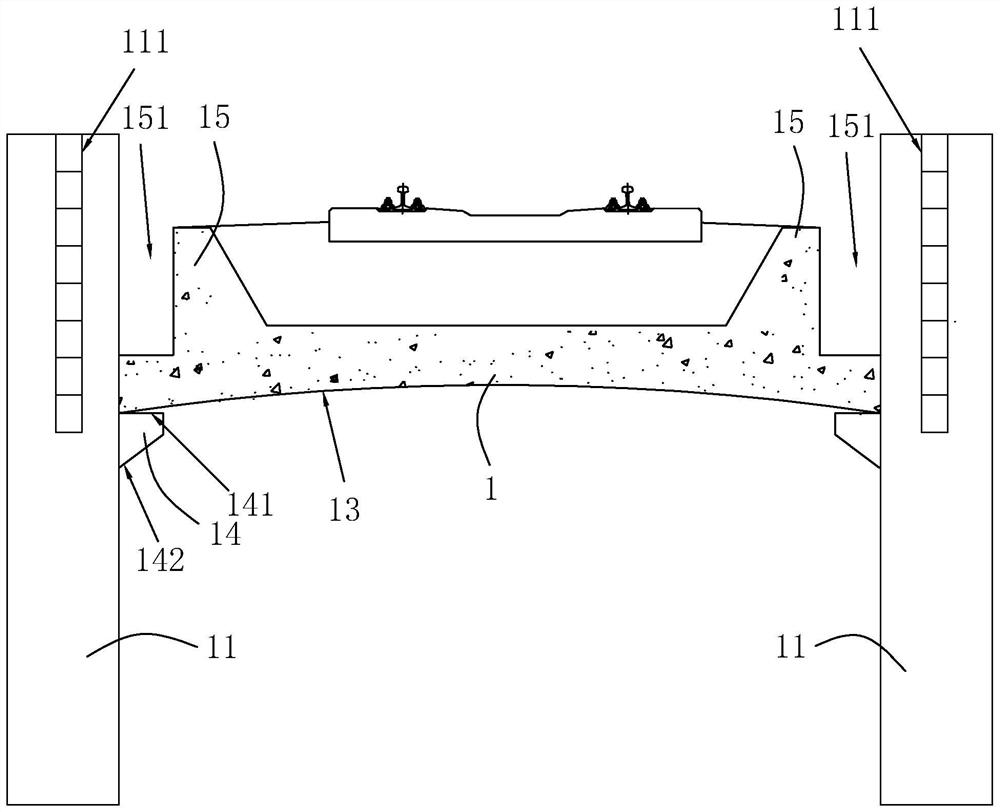

[0036] The embodiments of the present application disclose a roadbed support structure. refer to figure 1 , a roadbed support structure, including a base body 1, the base body 1 is made of concrete, and the roadbed support structure also includes a bearing member and a support member, the bearing member is used to carry the load on both sides of the base body 1, and the support member is used to The bottom of the base body 1 is supported.

[0037] like figure 1 As shown, the bearing member includes a plurality of bearing piles 11 arranged on both sides of the base body 1 and along the length direction of the base body 1, and the base body 1 is arranged on the plurality of bearing piles 11 on both sides; Retaining wall 111; in this embodiment, the bearing pile 11 is set as a pile foundation, and the pile foundation is a deep foundation composed of piles and a pile cap (referred to as a cap) connecting the top of the pile or a single foundation connected by a column and a pile...

Embodiment 2

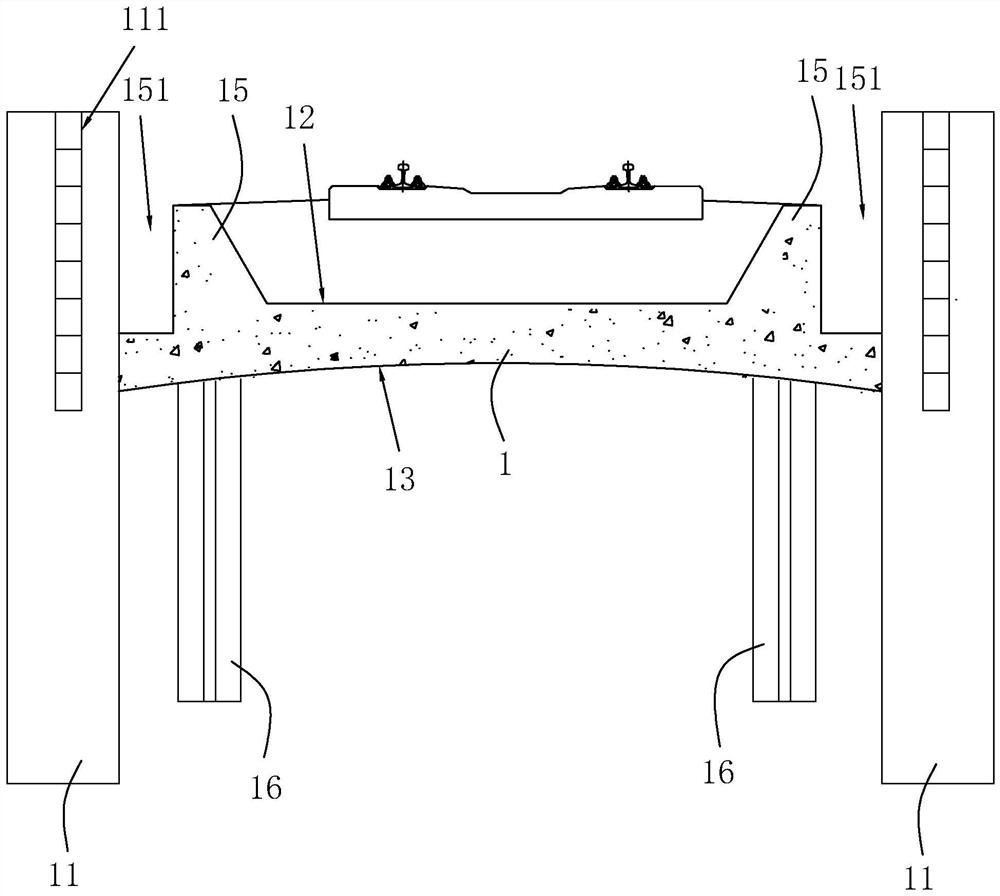

[0043] The difference between this embodiment and the first embodiment is that: figure 2 As shown, the support member includes support piles 16 , which are arranged in the vertical direction, and a plurality of support piles 16 are arranged below the base body 1 and on both sides of the base body 1 , and the plurality of support piles 16 are arranged along the length direction of the base body 1 . There are multiple groups. In this embodiment, four support piles 16 are provided below the base body 1 and located on both sides of the base body 1. The base body 1 is arranged on multiple groups of support piles 16, and the support piles 16 are set as rotary spray piles. The spray pile is to use the drilling rig to place the rotary jet grouting pipe and the nozzle at the design elevation of the pile bottom. After the pre-prepared slurry is passed through the high-pressure generating device, the liquid flow obtains huge energy, and then it is sprayed out from the nozzle at the side ...

Embodiment 3

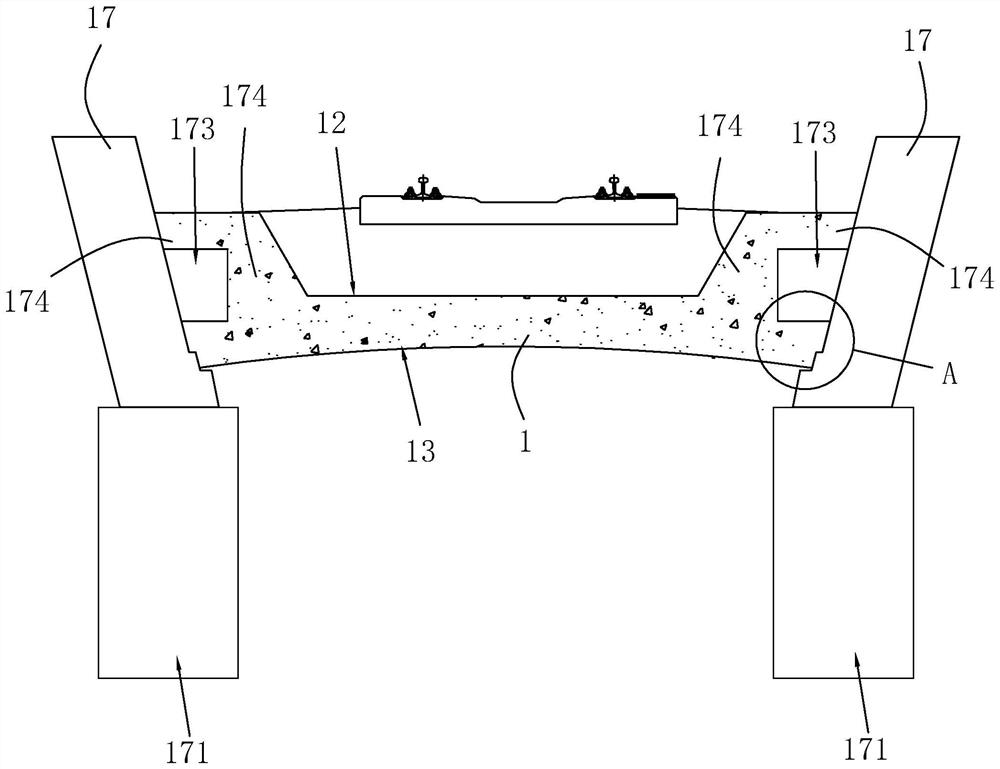

[0046] The difference between this embodiment and the first embodiment is that: image 3 As shown, the bearing member includes a bearing wall 17, both sides of the base body 1 are provided with bearing walls 17 along the length direction of the base body 1, and the distance between the bearing walls 17 on both sides is gradually along the direction from the bearing surface 12 to the force transmission surface 13. Reduced, the base body 1 is arranged between the bearing walls 17 on both sides; in this embodiment, the bearing walls 17 are arranged as gravity retaining walls, and the gravity retaining walls 111 are in the prior art, and the specific structure will not be carried out. In other embodiments, the distance between the opposite sides of the bearing walls 17 on both sides can also be gradually reduced, and the opposite sides of the bearing walls 17 on both sides are arranged vertically along the vertical direction.

[0047] like image 3 As shown, in order to further i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com