Weir-mold integrated double-wall steel cofferdam with vertical hidden enclosing purlins

A double-wall steel cofferdam and concealed technology, which is applied in construction, infrastructure engineering, etc., can solve the problems of excessive consumables and inconvenient construction, and achieve the effects of speeding up construction progress, convenient on-site construction, and optimizing the form of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

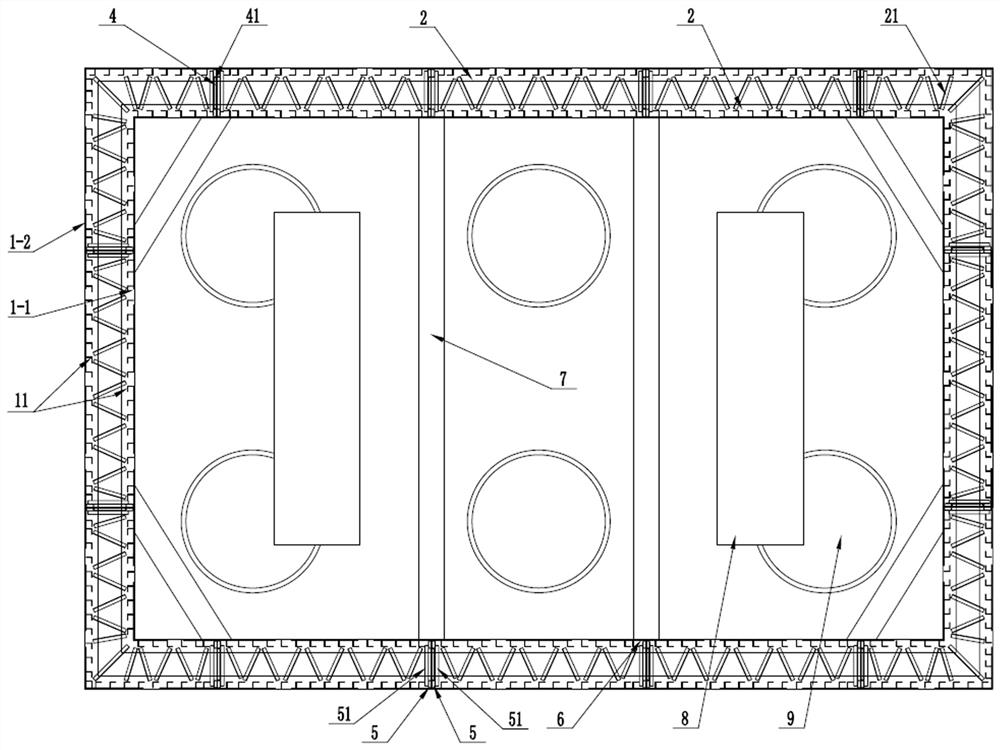

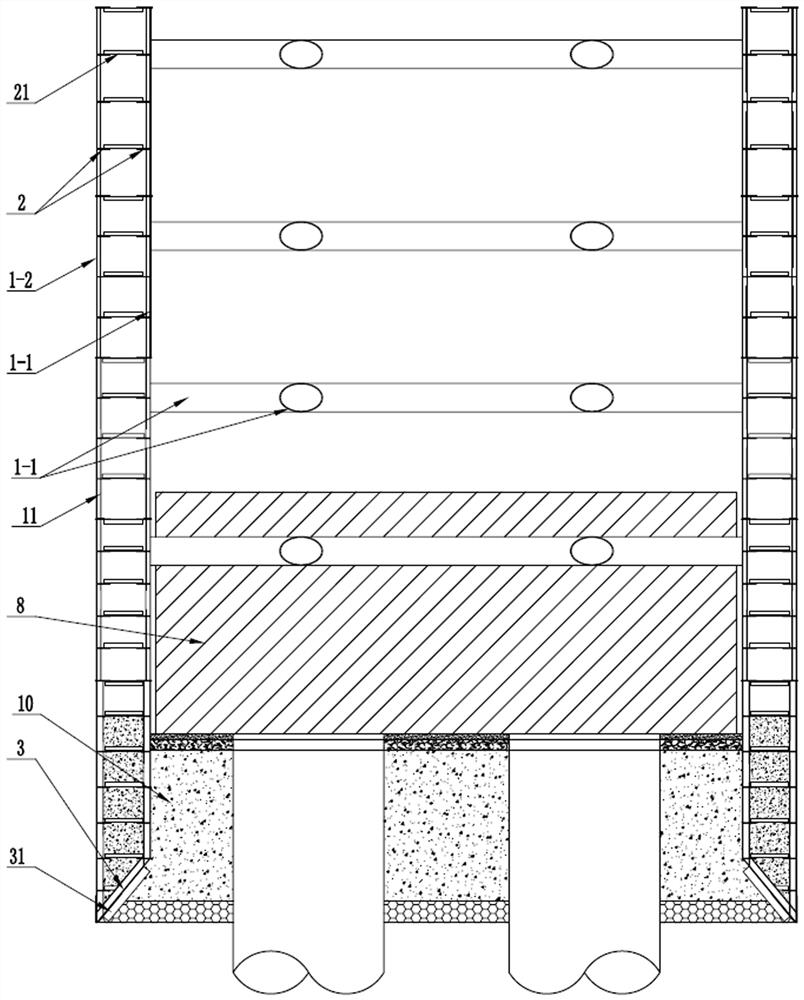

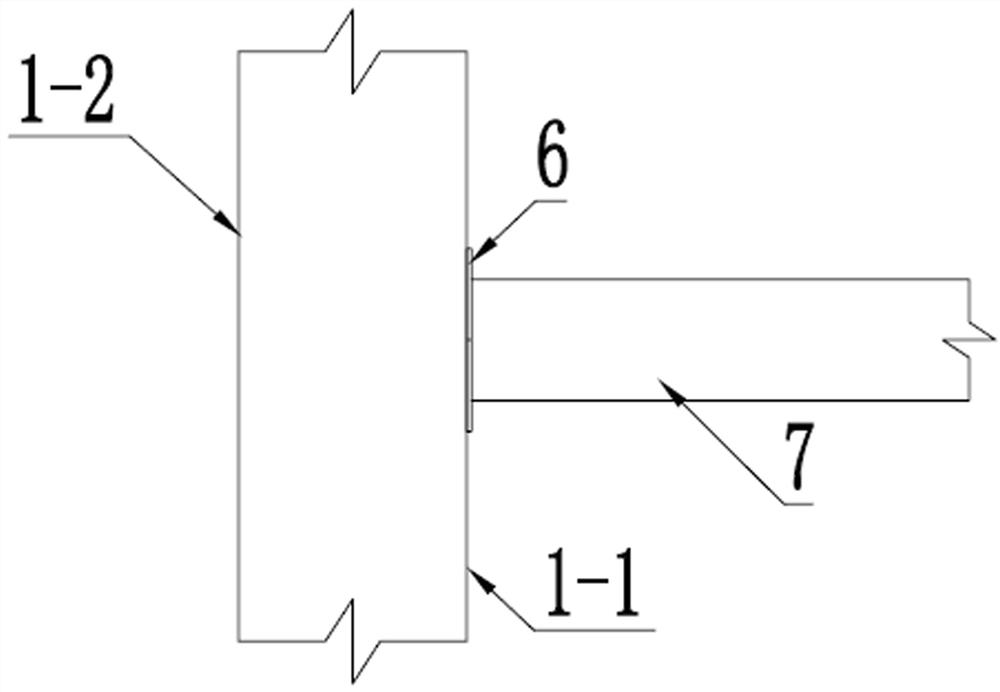

Embodiment 1

[0037] A double-wall steel cofferdam integrated with weir mold and vertical concealed purlin, which is formed by stacking and welding multiple layers of steel cofferdam, and each layer of steel cofferdam is formed by splicing and welding four right-angle plates and multiple plane plates The inner cavity of each layer of steel cofferdam is provided with inner support 7, and each of the right-angled plates and plane plates includes an inner wall plate 1-1 and an outer wall plate 1-2, and an inner wall plate 1-1 and an outer wall plate 1 -2 are respectively provided with multi-layer horizontal ring plates 2, the heights of the horizontal ring plates 2 on the inner wall plate 1-1 and the horizontal ring plates 2 on the outer wall plate 1-2 are corresponding, and the horizontal ring plates of two corresponding heights 2 are connected by a plurality of evenly distributed horizontal supports 21, and one side between the inner wall plate 1-1 and the outer wall plate 1-2 is sealed and w...

Embodiment 2

[0040] A double-wall steel cofferdam integrated with weir mold and vertical concealed purlin, which is formed by stacking and welding multiple layers of steel cofferdam, and each layer of steel cofferdam is formed by splicing and welding four right-angle plates and multiple plane plates The inner cavity of each layer of steel cofferdam is provided with inner support 7, and each of the right-angled plates and plane plates includes an inner wall plate 1-1 and an outer wall plate 1-2, and an inner wall plate 1-1 and an outer wall plate 1 -2 are respectively provided with multi-layer horizontal ring plates 2, the heights of the horizontal ring plates 2 on the inner wall plate 1-1 and the horizontal ring plates 2 on the outer wall plate 1-2 are corresponding, and the horizontal ring plates of two corresponding heights 2 are connected by a plurality of evenly distributed horizontal supports 21, and the horizontal supports 21 are all connected and fixed on the upper part of the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com