Device for liquefying biomass through cooperation of rotary tooth-shaped electrode discharge and heterogeneous catalyst

A heterogeneous catalyst and biomass technology, which is applied in the preparation of liquid hydrocarbon mixtures, the treatment of hydrocarbon oil, and the petroleum industry, can solve the problems of difficult liquefaction, low product quality, and poor mass and heat transfer capabilities, and achieve reduction Reduce the difficulty of discharge, improve the heat and mass transfer capacity of the solvent, and improve the quality of the liquefied product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

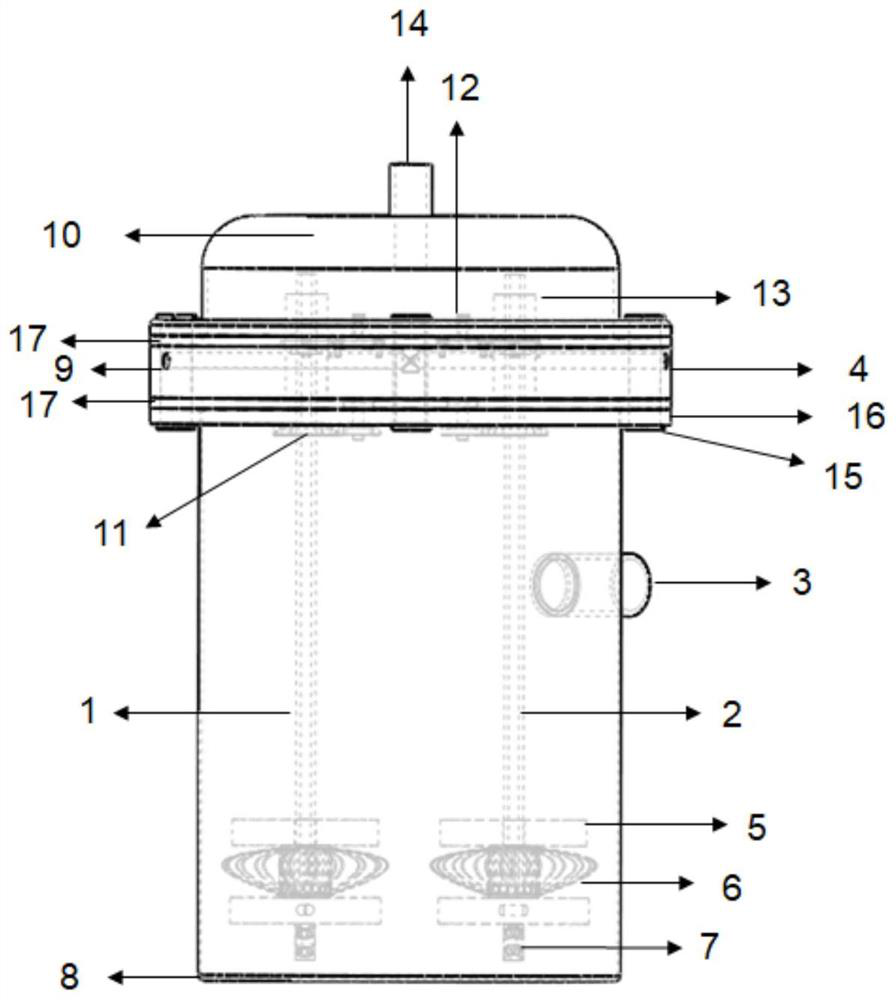

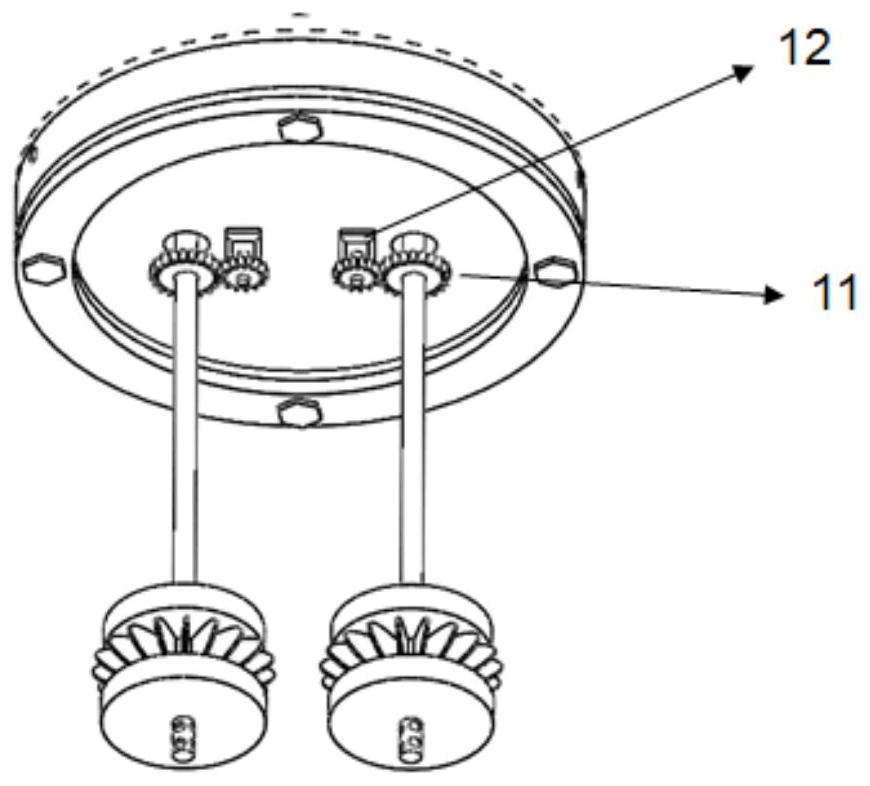

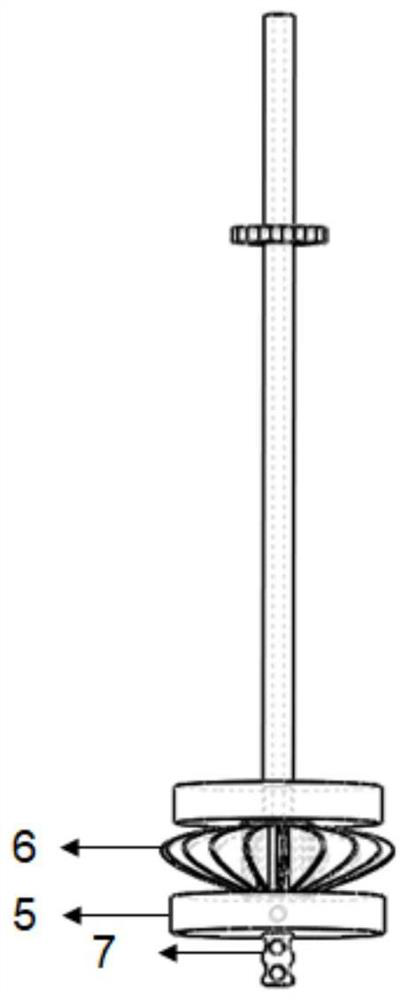

[0031] like figure 1 and figure 2 As shown, a rotating tooth-shaped electrode discharge cooperates with a heterogeneous catalyst to liquefy biomass device, including a reaction chamber 8, a high-voltage electrode 1 and a ground electrode 2 are arranged in the reaction chamber 8, the high-voltage electrode 1 and the ground electrode 2 are arranged in the reaction chamber 8. The electrodes 2 are arranged in parallel and have the same structure, including a hollow tube, a plurality of triangular tooth pieces 6 are fixed at the same lower end of each hollow tube, and a structural catalyst is provided above and below each of the triangular tooth pieces 6 5. The structural catalyst 5 is fixed on the hollow tube. The top of the reaction chamber 8 is provided with a sealing flange 16, an insulating cover 4 and a sealing cover 10 that are tightly connected in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com