Antibacterial and mildew-proof shoe material and sole preparation method

An antibacterial, mildew-proof, and shoe material technology, which is applied in the field of shoes, can solve the problems of inability to inhibit bacterial growth, inability to achieve complete antibacterial, and increase the cost of sole preparation, so as to avoid bacterial growth, inhibit bacterial growth, and antibacterial and anti-mold properties. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

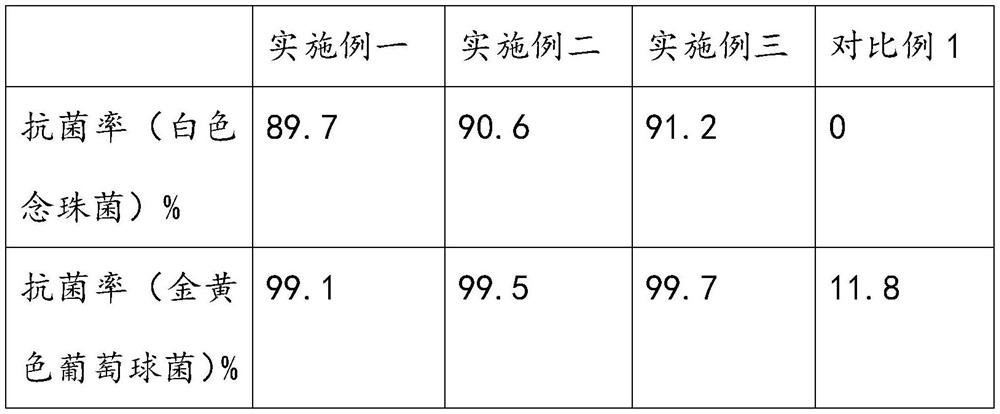

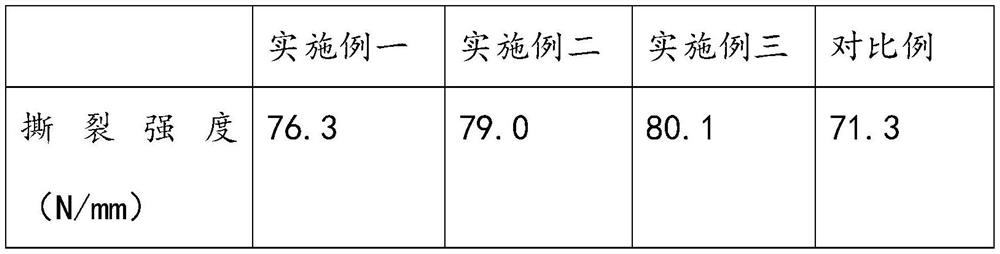

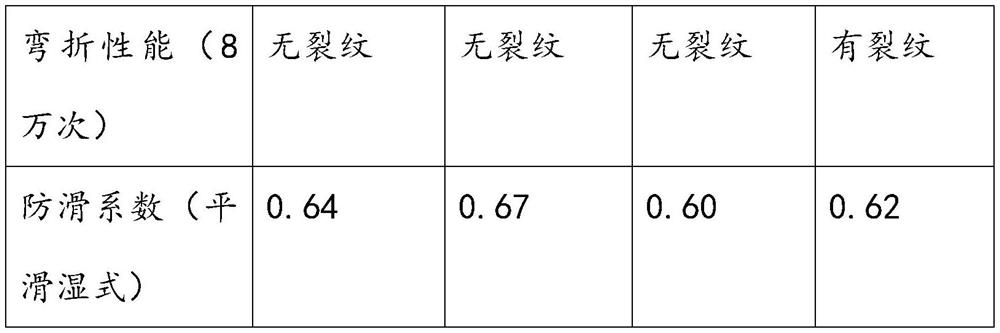

Examples

Embodiment 1

[0023] The antibacterial and mildew proof shoe material proposed by the present invention includes the following raw materials in parts by mass: EVA: 18 parts, OBC: 22 parts, natural rubber: 10 parts, foamed particles: 6 parts, natural rubber: 10 parts, and fiber particles: 4 parts, filler: 3 parts, antibacterial agent: 0.6 part, bacteriostatic agent: 0.5 part, vulcanizing agent: 0.3 part; the bacteriostatic agent adopts plant essential oil, and the plant essential oil is clove essential oil, rosemary essential oil or lavender essential oil. at least one. The antibacterial agent is composed of chlorohexadecylpyridine, benzyldimethylsilyl propylammonium chloride and nano-zinc oxide according to the mass ratio of 1:2:2.5. The plant essential oil used in this embodiment is clove essential oil, and the plant essential oil is prepared by steam distillation.

[0024] The steam distillation method includes the following steps: step 1: pulverize the selected plants with a small grain...

Embodiment 2

[0031] The antibacterial and mildew proof shoe material proposed by the present invention includes the following raw materials in parts by mass: EVA: 20 parts, OBC: 23 parts, natural rubber: 12 parts, foamed particles: 8 parts, fiber particles: 5 parts, filler: 4 parts, antibacterial agent: 0.7 part, antibacterial agent: 0.6 part, vulcanizing agent: 0.4 part; antibacterial agent is composed of chlorohexadecylpyridine, benzyldimethylsilyl ammonium chloride and nano-zinc oxide according to mass The ratio is 1.5:1.5:3; the bacteriostatic agent is plant essential oil, and the plant essential oil is composed of clove essential oil, rosemary essential oil and lavender essential oil in a mass ratio of 2:1, and the plant essential oil is prepared by steam distillation.

[0032] The steam distillation method includes the following steps: step 1: pulverize the selected plants with a small grain pulverizer; accurately weigh a certain amount of dry plant powder and place it in a distillati...

Embodiment 3

[0039] The antibacterial and mildew proof shoe material proposed by the present invention includes the following raw materials in parts by mass: EVA: 22 parts, OBC: 24 parts, natural rubber: 14 parts, foamed particles: 10 parts, fiber particles: 6 parts, filler: 5 parts, antibacterial agent: 0.8 part, antibacterial agent: 0.7 part, vulcanizing agent: 0.5 part; antibacterial agent is composed of chlorohexadecylpyridine, benzyldimethylsilyl ammonium chloride and nano-zinc oxide according to mass The ratio is 2:1:2. The bacteriostatic agent adopts plant essential oil, and the plant essential oil is composed of clove essential oil and lavender essential oil in a mass ratio of 1:1, and the plant essential oil is prepared by steam distillation.

[0040] The steam distillation method includes the following steps: step 1: pulverize the selected plants with a small grain pulverizer; accurately weigh a certain amount of dry plant powder and place it in a distillation flask, add a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com