Paper cup and paper box recycling machine

A technology for recycling machines and cartons, which is applied in garbage collection, household utensils, garbage cleaning, etc. It can solve the problems that paper cups and cartons are easy to mold and smell, inconvenient to operate, and occupy a large space, so that it is not easy to mold and smell, Ease of recycling and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

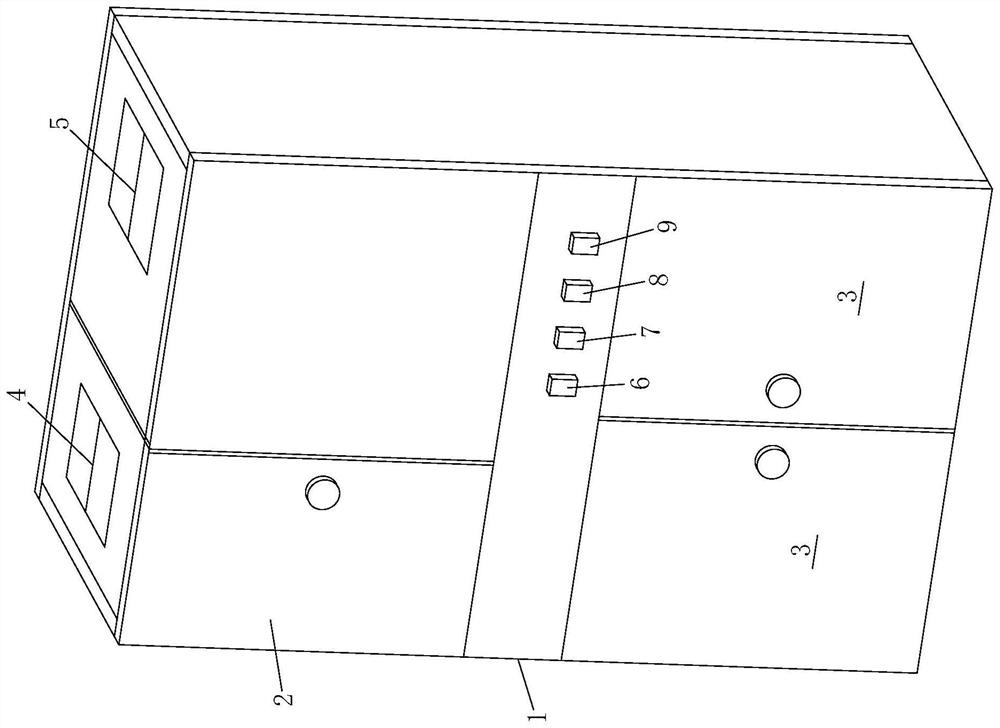

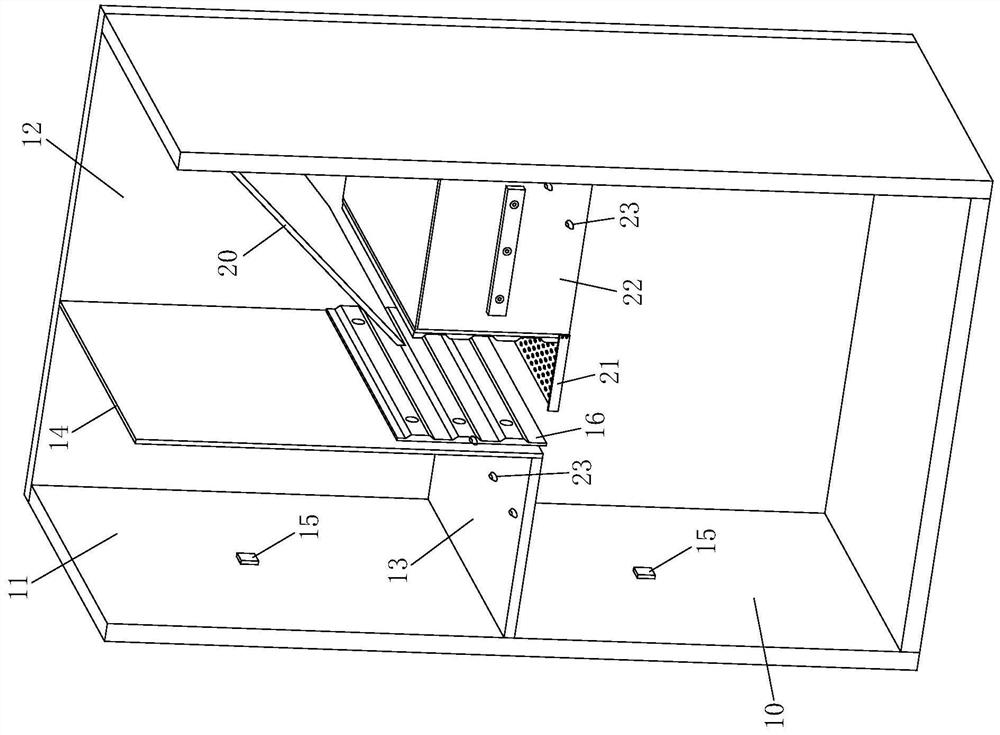

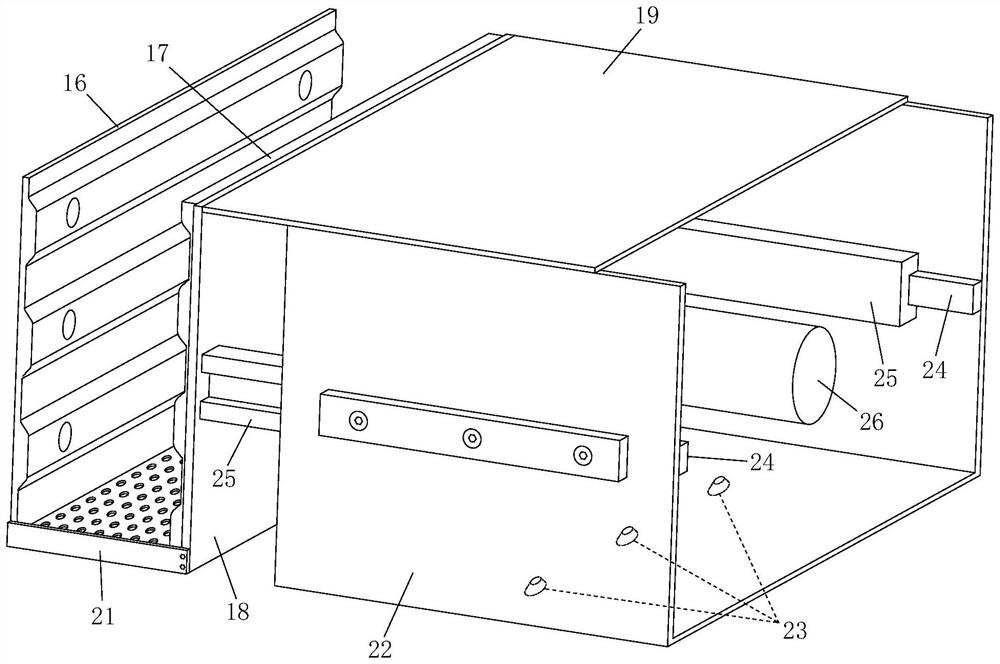

[0018] Example: see Figure 1-Figure 4 , a paper cup carton recycling machine, including a cabinet, the cabinet is provided with a horizontal partition and a vertical partition, the horizontal partition and the vertical partition divide the inner cavity of the cabinet into a plastic part collection box, a paper part collection box and Paper storage box, the top panel of the cabinet is provided with plastic and paper delivery ports corresponding to the plastic collection box and paper collection box, and the front panel of the cabinet is provided with a single sheet corresponding to the plastic collection box and the paper storage box. open door and double door; the bottom of the paper collection box is provided with a paper flattening device, the paper flattening device includes a static pressure plate and a dynamic pressure plate assembly, the static pressure plate is arranged at the lower part of the vertical partition, the dynamic pressure plate The pressure plate assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com