PCB copper-clad plate processing and cutting all-in-one machine

An all-in-one machine and copper-clad laminate technology, which is applied in metal processing, insulating substrate/layer processing, printed circuit, etc., can solve the problems that the safety of processing personnel cannot be guaranteed, the efficiency of copper-clad laminates is reduced, and the processing area is occupied. Eliminate processing hazards, wide application range, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings.

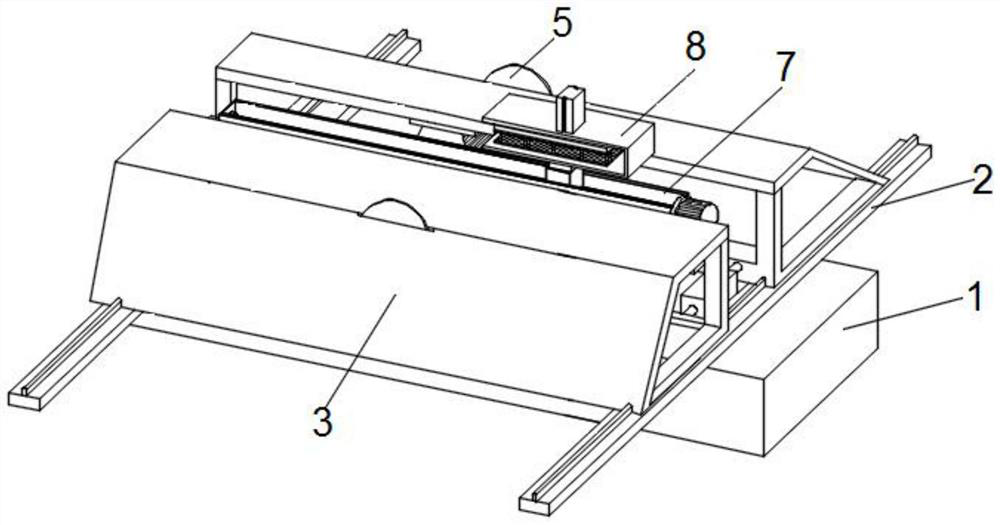

[0038] see Figure 1-5 , this embodiment provides an integrated machine for processing and cutting a PCB copper clad laminate, which includes a base 1;

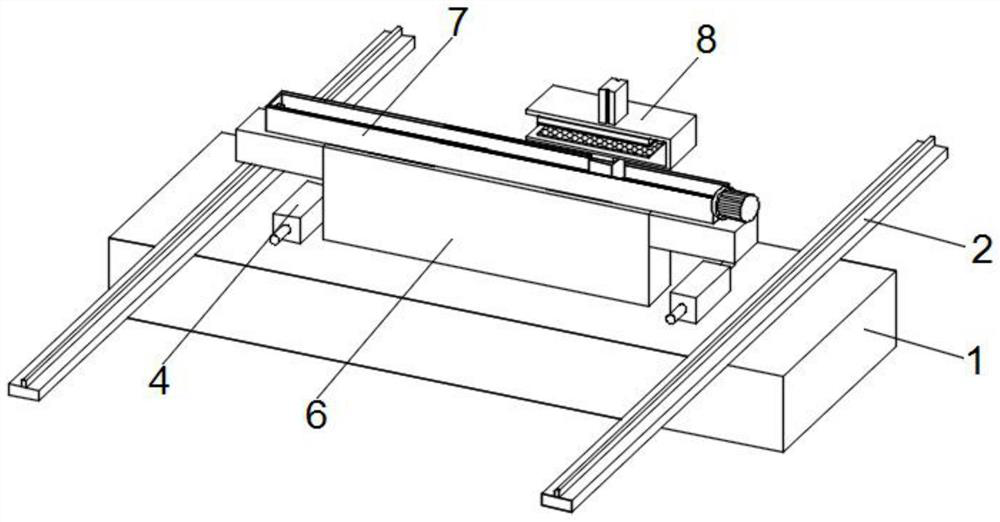

[0039] The above-mentioned PCB copper clad laminate processing and cutting machine also includes two linear guide rails 2, two cutting and blanking mechanisms 3, two bidirectional telescopic devices 4, two cutting mechanisms 5, a lifting seat 6, a linear drive mechanism 7 and a positioning mechanism 8.

[0040] Wherein, each linear guide 2 is fixedly installed on the base 1 .

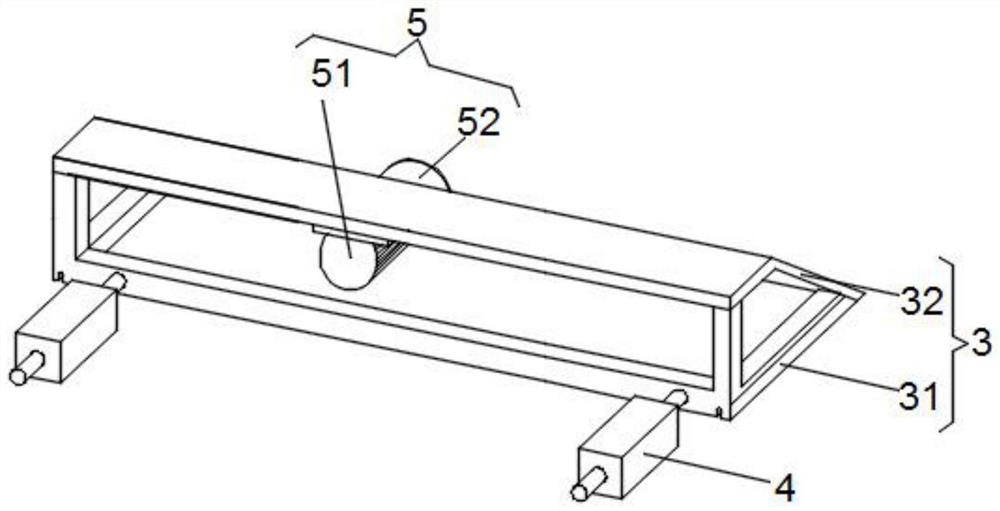

[0041] Wherein, the two cutting and blanking mechanisms 3 are movably connected between the two linear guide rails 2; each cutting and blanking mechanism 3 includes a support frame 31 and a processing blanking plate 32 fixedly installed on the upper part of the support frame 31;

[0042] The lower surface of the support frame 31 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com