Special pulse bag-type dust collector for purifying tail gas of closed submerged arc furnace

A technology of tail gas purification and pulse bagging, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve problems such as no good solutions, hidden safety hazards, and flash explosion accidents, so as to ensure the horizontal pressure operation of equipment , Prevent flash explosion and protect equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

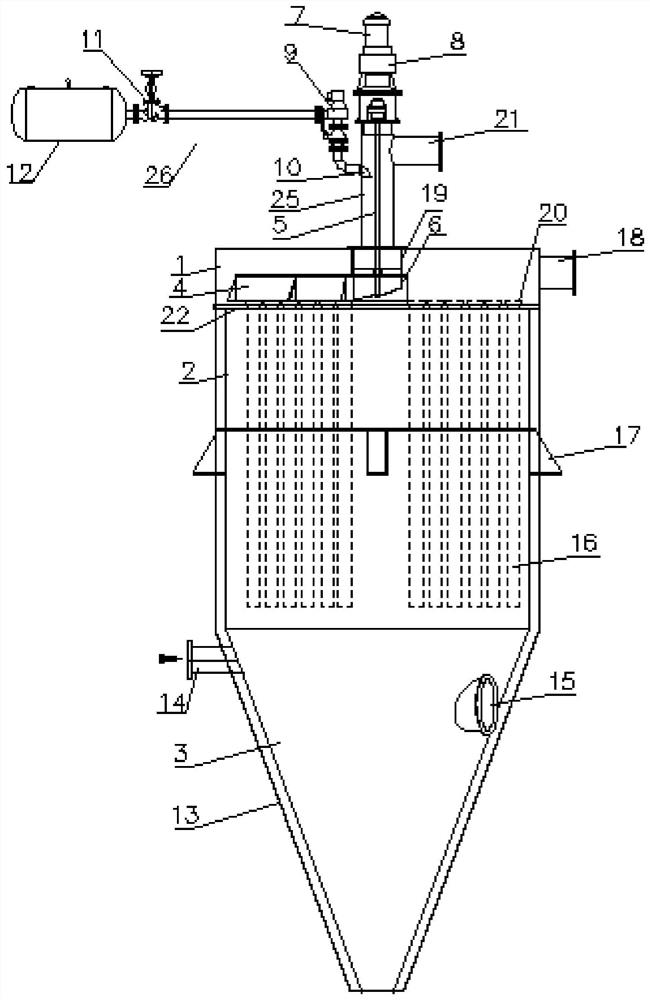

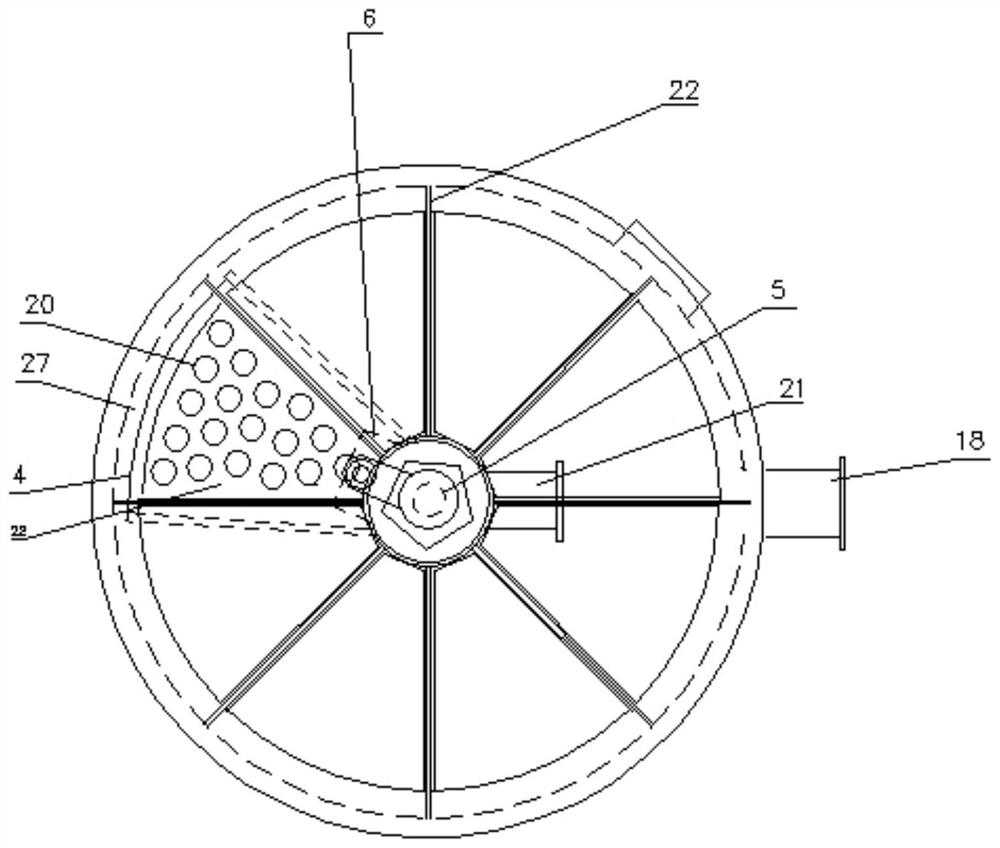

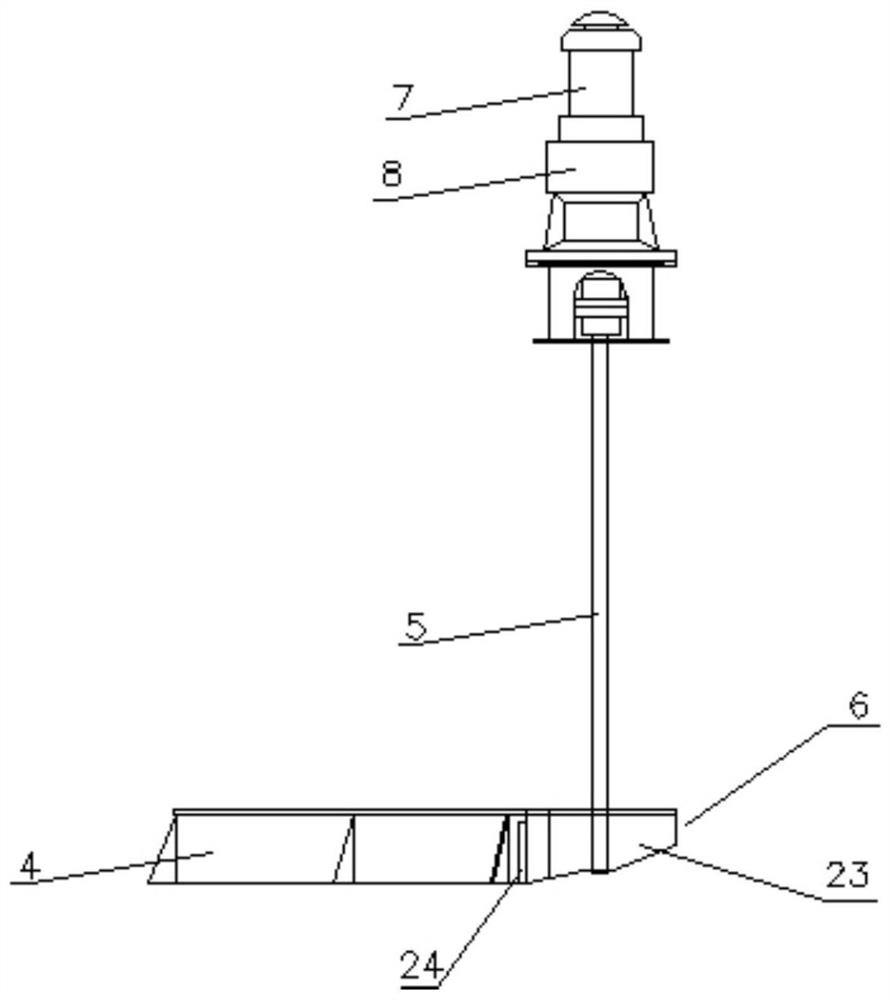

[0023] The main body of the dust cleaning rotary nozzle 6 is a cylinder 23, the left side wall of the cylinder 23 is welded with the enclosure plate at the straight edge of the fan surface of the dust cleaning rotary cover 4, and the cylinder 23 of the dust cleaning rotary nozzle 6 is facing the side of the fan surface A nozzle 24 communicating with the cylinder 23 is provided, and a guide pipe 19 is arranged in the middle of the upper casing 1. The upper end of the guide pipe 19 is vertically welded with the upper casing 1 and communicated with the dust cleaning and blowback pipe 25. The lower end of the flow pipe 19 is provided with a bearing sleeve and the lower end of the bearing rotatably fixed rotating shaft 5 at the position of the tube axis.

Embodiment 2

[0025] The right side of the upper box body 1 is provided with an exhaust gas purification outlet pipe 18, the left side of the ash hopper 3 is provided with an exhaust gas ash accumulation pipe 14, the right side of the ash hopper 3 is provided with an inspection manhole door 15, and the middle end of the middle box body 2 is provided for The column support platform 17 supporting the pulse bag filter for exhaust gas purification of closed submerged arc furnace.

Embodiment 3

[0027] The nitrogen ash cleaning device 26 includes a compressed nitrogen gas storage tank 12 , a control valve 11 , a pulse valve 9 , and a ash cleaning nozzle 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com