A method for controlling oxygen content in a silicon wafer carrying area of a semiconductor device

A technology of a bearing area and a control method, applied in the field of control devices for realizing the method, can solve the problems of shortening the control target time, easy aging of the actuator, reducing frequent actions, etc., achieving good comprehensive effects, avoiding frequent actions, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

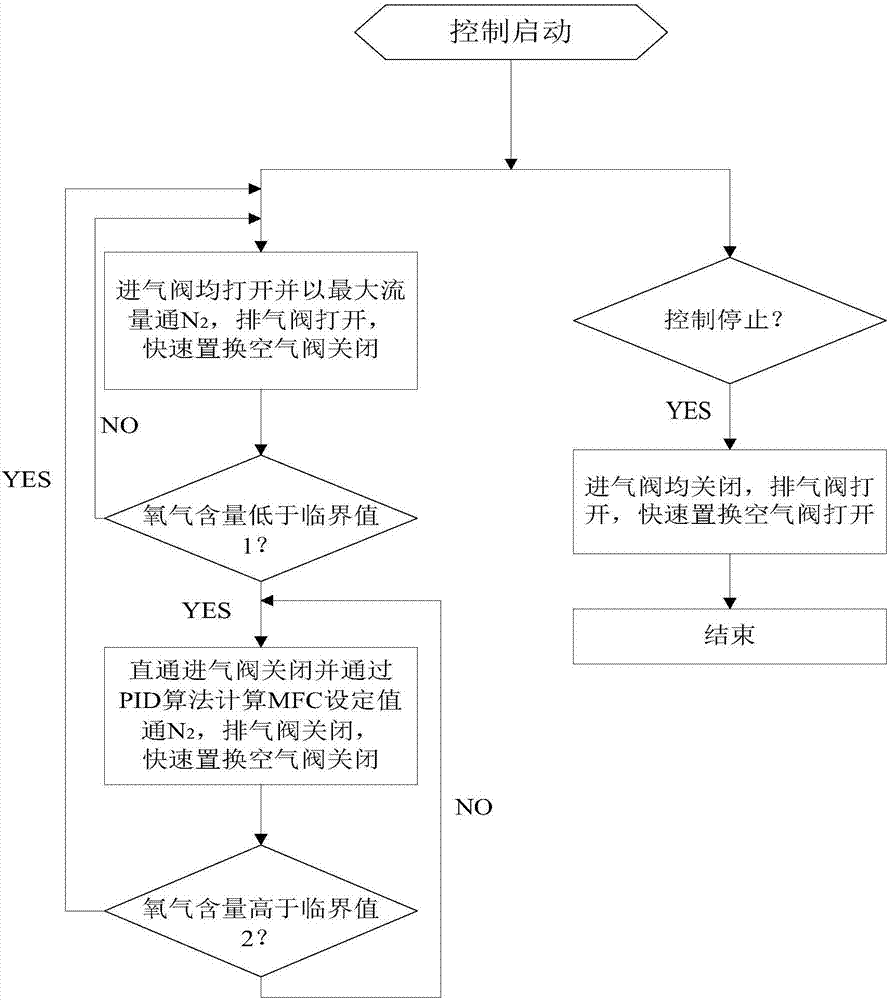

[0022] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] In this example, see figure 1 , figure 1 It is a control flowchart of the oxygen content control method of the present invention. As shown in the left column of the figure, when the present invention controls the oxygen content in the silicon wafer bearing area of the semiconductor diffusion equipment, a staged method is adopted in the control process, and the rapid nitrogen blowing is preset first, and when the oxygen content is lower than a certain value , and then switch to PID control mode to blow nitrogen slowly. Specifically divided into two steps:

[0024] The first step is to enter the stage of rapid nitrogen blowing. At the beginning of the control, start the control system, close the rapid replacement air valve, open the exhaust valve, the straight-through intake valve and the intake valve with MFC,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com