Zinc oxide-carbon core-shell nanoparticles and preparation and application thereof

A nanoparticle and zinc oxide technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as limited modification effect, inability to suppress internal defects of zinc oxide, and poor stability of the composite interface layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

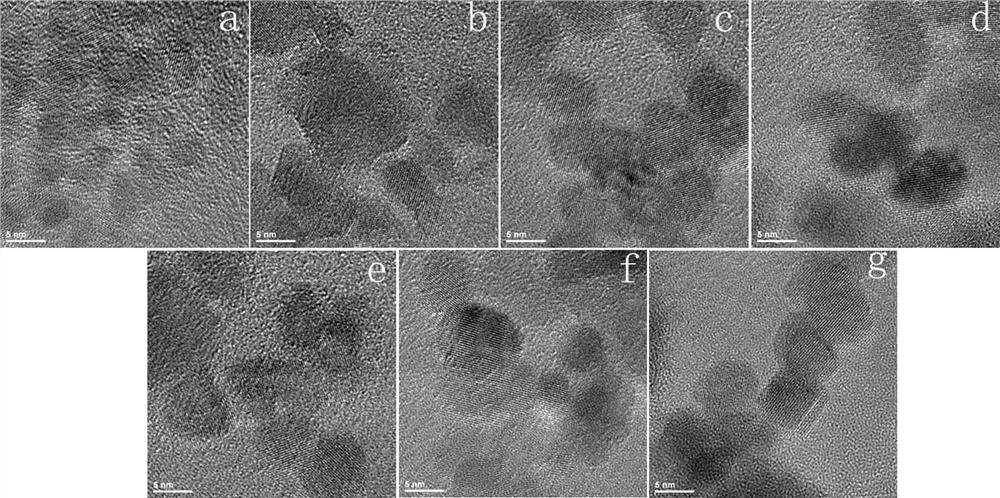

Image

Examples

Embodiment 1

[0048] Weigh 10 mg of o-phenylenediamine, add it to 20 mL of nano-ZnO methanol solution with a concentration of 10 mg / mL, and ultrasonically disperse for 30 min to form a ZnO-o-phenylenediamine mixture with a carbon source material of 5% by mass of nano-ZnO.

[0049] The above-mentioned ZnO o-phenylenediamine mixed solution was placed in a polytetrafluoroethylene sealed tank, placed in a matching reaction kettle, heated to 180° C. in an oven, and subjected to a solvothermal reaction for 10 hours.

[0050] After the reaction was completed, the temperature was naturally cooled, the reaction product was taken out, the supernatant was discarded by centrifugation, and the precipitate was dispersed in methanol as a solvent by strong ultrasonic waves to prepare ZnO@C-5 core-shell nanoparticles.

Embodiment 2

[0052] Weigh 20 mg of o-phenylenediamine, add it to 20 mL of nano-ZnO methanol solution with a concentration of 10 mg / mL, and ultrasonically disperse it for 30 min to form a ZnO-o-phenylenediamine mixture whose carbon source material is 10% by mass of nano-ZnO.

[0053] The above-mentioned ZnO o-phenylenediamine mixed solution was placed in a polytetrafluoroethylene sealed tank, placed in a matching reaction kettle, heated to 180° C. in an oven, and subjected to a solvothermal reaction for 10 hours.

[0054] After the reaction was completed, the temperature was naturally cooled, the reaction product was taken out, the supernatant was discarded by centrifugation, and the precipitate was dispersed in the solvent methanol with strong ultrasonic waves to prepare ZnO@C-10 core-shell nanoparticles.

Embodiment 3

[0056] Weigh 60 mg of o-phenylenediamine, add it to 20 mL of nano-ZnO methanol solution with a concentration of 10 mg / mL, and ultrasonically disperse it for 30 min to form a ZnO-o-phenylenediamine mixture with a carbon source material of 30% by mass of nano-ZnO.

[0057] The above-mentioned ZnO o-phenylenediamine mixed solution was placed in a polytetrafluoroethylene sealed tank, placed in a matching reaction kettle, heated to 180° C. in an oven, and subjected to a solvothermal reaction for 10 hours.

[0058] After the reaction was completed, the temperature was naturally cooled, the reaction product was taken out, the supernatant was discarded by centrifugation, and the precipitate was dispersed in the solvent methanol with strong ultrasonic waves to prepare ZnO@C-30 core-shell nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com