Laboratory safety inspection method and device based on Internet of Things

A laboratory and Internet of Things technology, applied in the field of laboratory management, can solve problems such as reduced efficiency, high labor intensity of managers, and unguaranteed time density of manual inspections, and achieve the effect of avoiding human loopholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

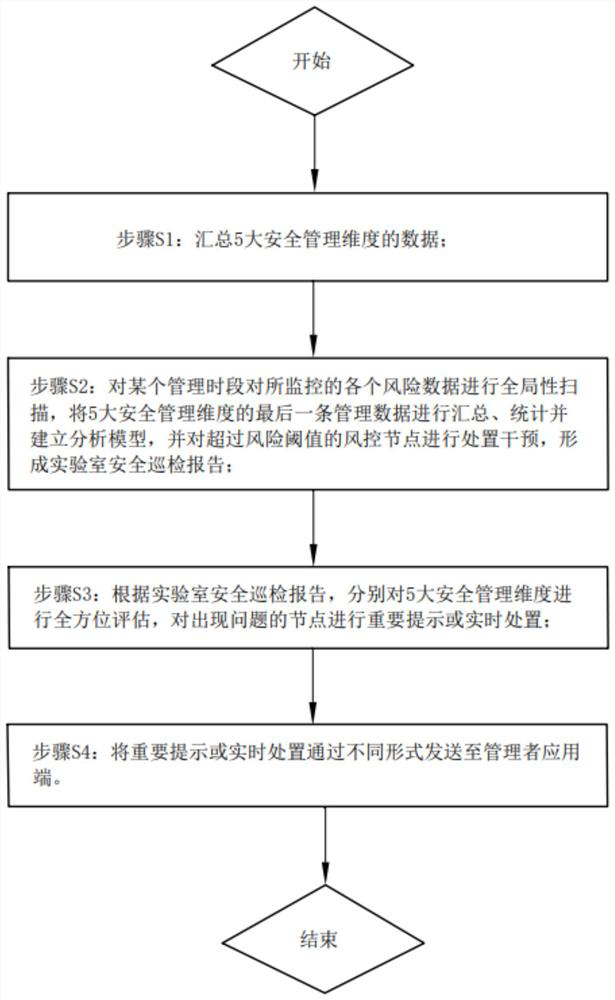

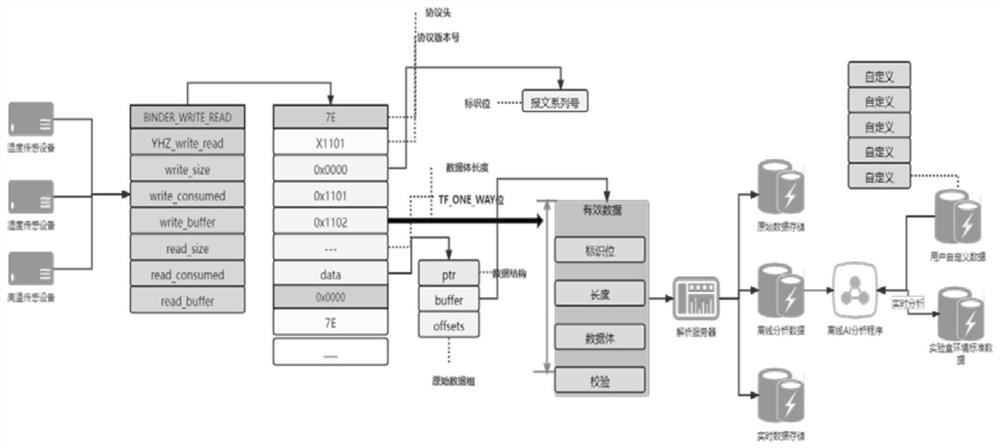

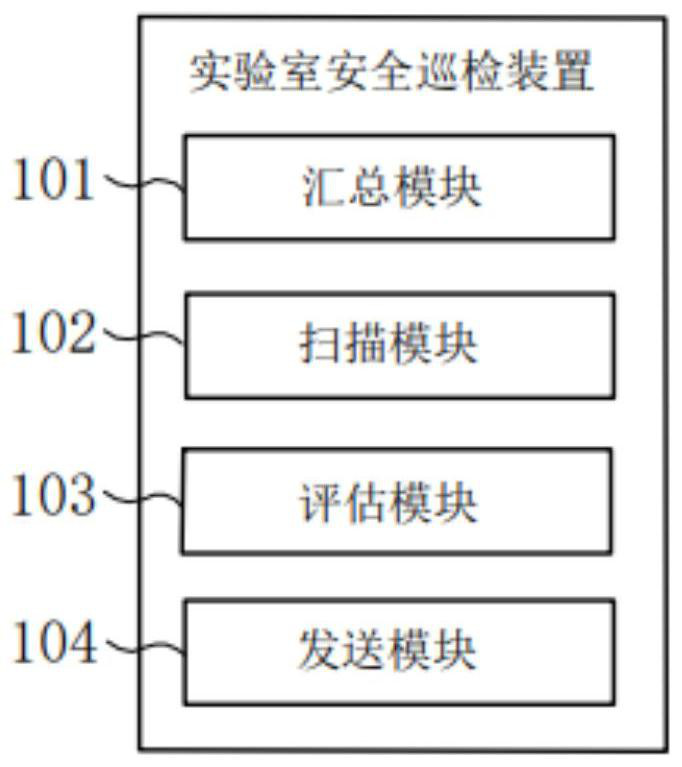

Method used

Image

Examples

Embodiment 1

[0079] Example 1: The access control security device that monitors the safe access of laboratory personnel included in the laboratory safety inspection method, obtains the access authority to enter the laboratory through RFID or face recognition, and records the data of the safe access of these personnel Such as: personnel ID, entry and exit time, authorization status, number of entry and exit times, dressing status, etc. are summarized and reported to the system for various statistical analysis, and finally various data analysis models for laboratory personnel access security are formed to provide different business scenarios for visual display ;

Embodiment 2

[0080] Embodiment 2: The IOT hardware terminal (power management terminal and communication management terminal) included in the laboratory safety inspection method to manage and control the safe operation and maintenance of the instrument Data such as fault diagnosis, maintenance and measurement prompts are reported to the system for various statistical analysis, and finally various data analysis models for safe operation and maintenance of the instrument are formed to provide different business scenarios for visual display;

Embodiment 3

[0081] Example 3: The intelligent management device for the safety management of the use of hazardous chemical materials in the laboratory included in the laboratory safety inspection method, and the real-time situation of the reagent inventory, the status of receiving / returning the reagent, and the authority to use the hazardous chemical during the use of the hazardous chemical. Real-time data such as traceability and storage condition records are reported to the system for various statistical analysis, and finally various data analysis models for the safety monitoring of the use of hazardous chemical materials are formed to provide different business scenarios for safety control;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com