Method for inscribing fiber bragg grating face by face based on high-refractive-index matching liquid

A technology of optical fiber Bragg and high refractive index, applied in cladding optical fiber, optical waveguide light guide, optical, etc., to achieve the effect of improving mechanical properties, uniform distribution of fiber core, and suppressing response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

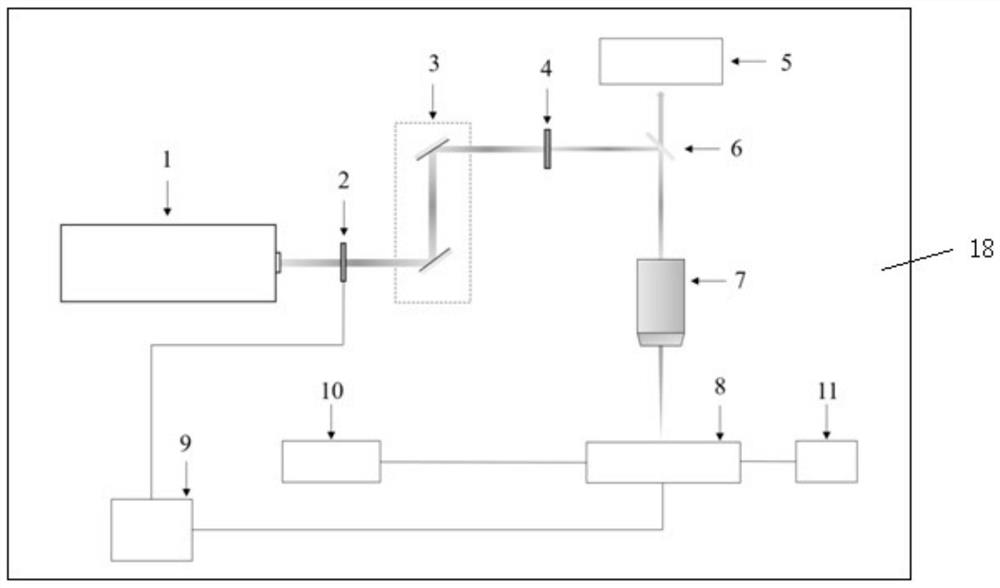

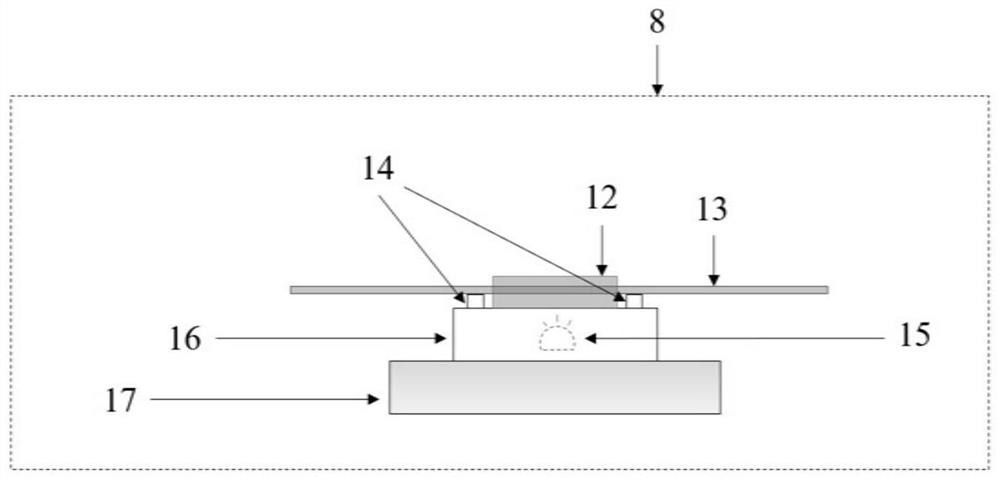

[0032] exist figure 1 , 2 In this embodiment, the device for surface-by-surface writing of fiber Bragg gratings based on high refractive index matching liquid is that the optical platform 18 is provided with a femtosecond laser 1, and the optical platform 18 is provided with an optical switch 2 and a plane mirror reflection group 3 along the laser output direction. , diaphragm 4, plane mirror 6, microlens group 7, 3D micromachining platform 8, CCD camera 5 is installed on microlens group 7, CCD camera 5 is used for real-time monitoring of the grating writing process, 3D micromachining platform 8 A three-dimensional right-angle manual adjustment frame 16 is installed on the three-dimensional electric displacement stage 17. The three-dimensional right-angle manual adjustment frame 16 is equipped with a glass slide, a fiber optic clamp 14 and an LED light 15. The LED light 15 is located under the glass slide, and the fiber clip is clamped on Hold the optical fiber 13 to be writt...

Embodiment 2

[0044] This embodiment provides a method for surface-by-surface writing of ultra-short gratings and ultra-short grating pairs based on a high-refractive-index matching liquid, wherein the repetition frequency of the laser is 200 Hz, the power is 6 μW, the femtosecond laser 1 is turned on, and the laser power is stabilized to pass through The computer 9 controls the three-dimensional electric displacement stage 17 to move the three-dimensional electric displacement stage 17 along the axis of the optical fiber, and sets the grating length to 100 μm. After writing an ultra-short grating, the three-dimensional electric displacement stage 17 is controlled to move 3000 μm along the optical fiber, and the writing The second ultra-short grating with a length of 100 μm; then turn off the optical switch 2 and the three-dimensional electric displacement stage 17, the writing is over, and the written fiber grating is taken out. Other operation steps are the same as in Example 1.

[0045] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Extinction ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com